Automatic production device for precise machining of rotating pin holes of ratchet wrench heads

An automatic production, wrench head technology, applied in metal processing equipment, drilling/drilling equipment, metal processing and other directions, can solve the problems of flying knife, large drilling position error, reduce production efficiency, etc., to reduce manual operation, The effect of realizing the processing position and ensuring the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

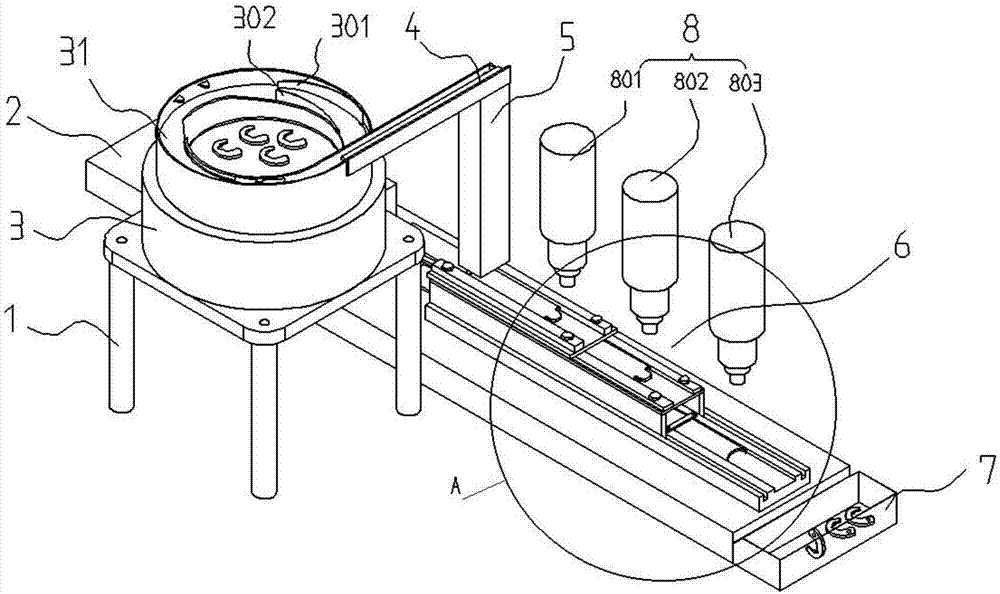

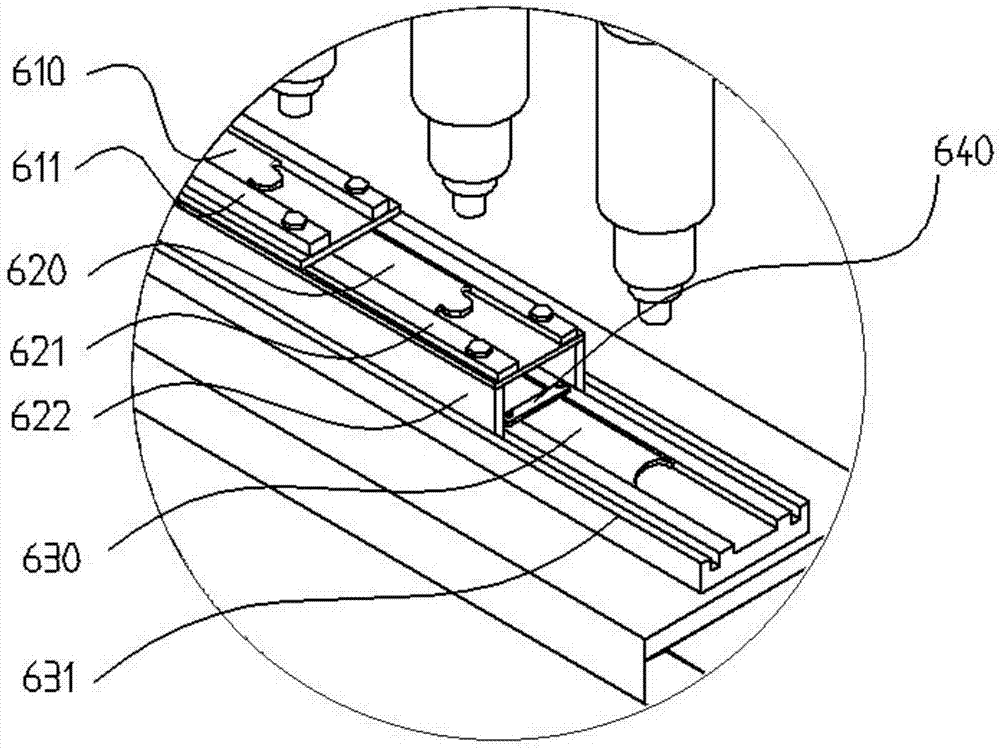

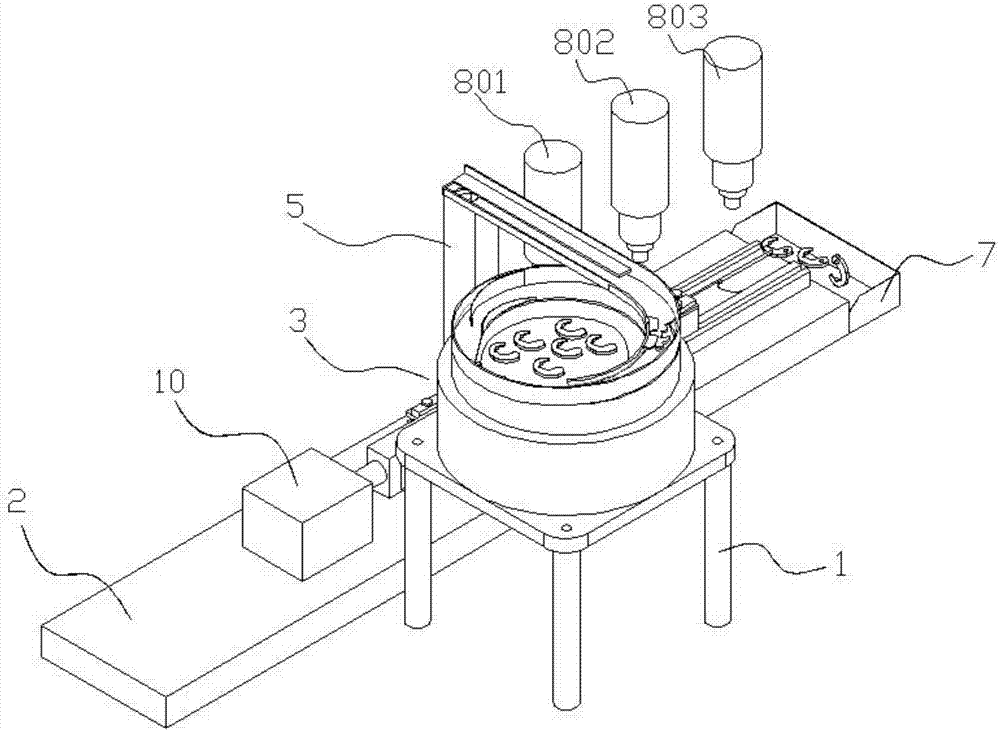

[0027] Such as Figure 1-Figure 7 Shown, the concrete structure of the present invention is: a kind of finishing automatic production equipment that is used for ratchet wrench head repinning hole, it comprises the vibrating feeding tray 3 that is arranged on the frame 1 and the drilling machine device 8; Said vibrating feeding tray 3 is provided with a spiral surrounding feeding plate 31; the spiral surrounding feeding plate 31 is provided with a limited layer guide plate 301, a discharge trough 303, and a material selection trough 304 in sequence along the moving direction of the parts; The baffle pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com