A warehouse layout management method and system

A management method and management system technology, applied in data processing applications, logistics, computing, etc., can solve the problems of adding, deleting, and modifying storage locations, inability to distinguish between storage areas and storage locations, and inability to effectively differentiate, and achieve fast The effect of sorting, saving management costs and reducing management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 (a storage layout management method)

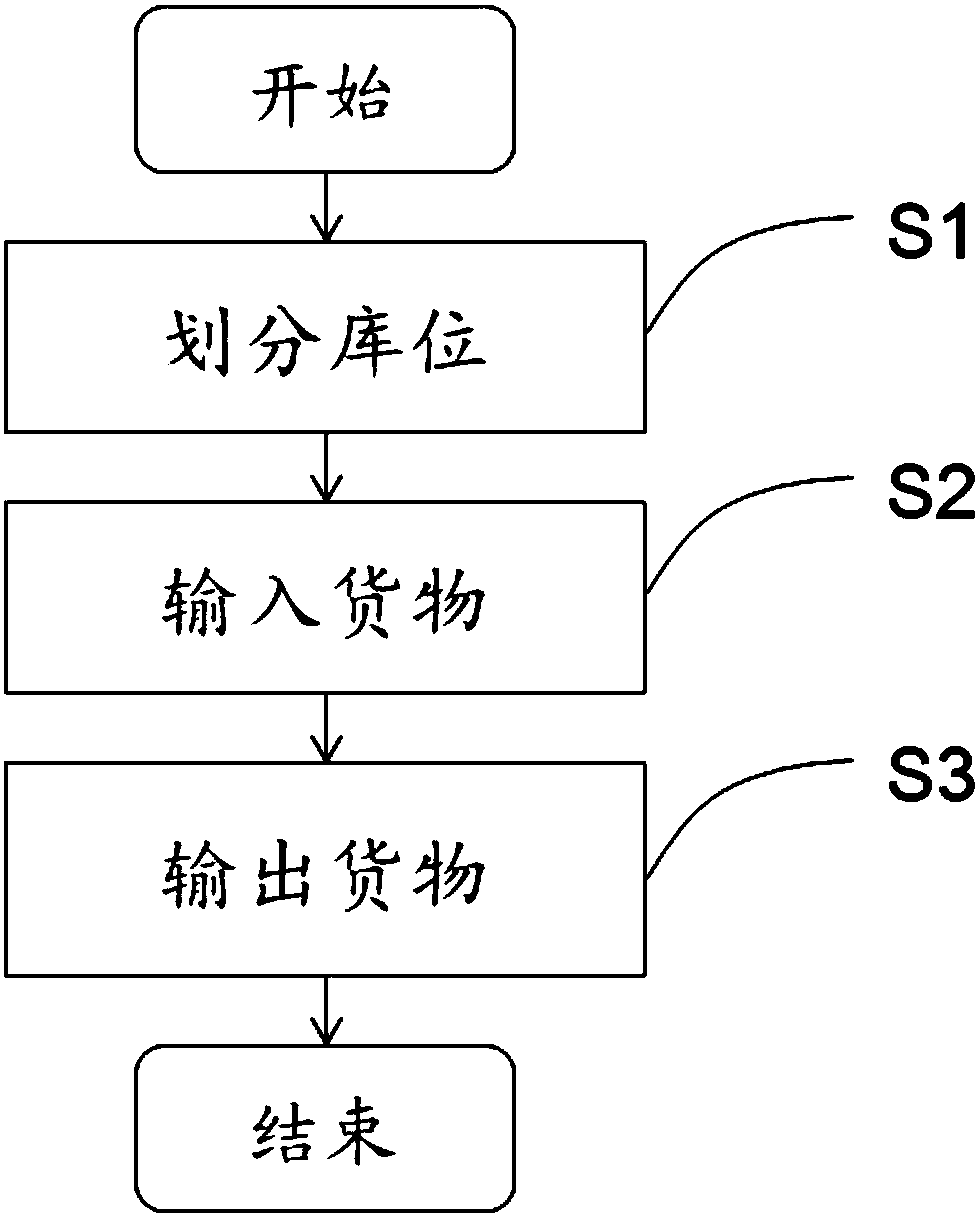

[0051] Such as figure 1 Shown is a schematic flow chart of a more preferred implementation of the storage layout management method of the present invention, the method includes the following steps:

[0052] Divide warehouse locations: divide the warehouse into several sub-warehouses, each of which includes several warehouse areas, each of which corresponds to a commodity type, and each of the warehouse areas is provided with several warehouse locations;

[0053] Input goods: identify the identification code of the goods to be input, and match the barcode with the type of goods in the storage area. If the match is successful, perform the first determination procedure; if the match is unsuccessful, perform warehouse building;

[0054] Export goods: Obtain demand information and match it with inventory information. If the match is successful, the goods will be exported; if the match is unsuccessful, the demand informatio...

Embodiment 2

[0057] Embodiment 2 (a storage layout management method)

[0058] In combination with the above basic implementation manners, this embodiment is another preferred implementation manner.

[0059] The difference between this embodiment and the foregoing embodiment is:

[0060] The first determination procedure performs the following steps:

[0061] Obtain the storage area information corresponding to the product type, obtain the usage of the storage location, and determine whether there is a vacant storage location; if there is, the goods will be put into the warehouse, if not, the warehouse will be built and the goods will be put into the warehouse.

[0062] Through this step, it is possible to distinguish whether the warehouse area and the warehouse location are in the same operation process, so as to invest different resources for management accordingly to meet the needs of actual warehouse management.

[0063] The rest of the implementation manners are the same as the abov...

Embodiment 3

[0064] Embodiment 3 (a storage layout management method)

[0065] In combination with the above basic implementation manners, this embodiment is another preferred implementation manner.

[0066] The difference between this embodiment and the foregoing embodiment is:

[0067] The demand information includes one or more of product name, quantity, model, and identification code information.

[0068] Through the division of demand information, the content of customer demand can be clarified, so as to conveniently and effectively prepare for the matching of the subsequent process, improve the efficiency of matching in the subsequent process, and improve the efficiency of warehousing and logistics operation and management.

[0069] The rest of the implementation manners are the same as the above-mentioned embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com