Parallel connection plate wrapping mechanism of storage battery pole plate

A battery and chip packaging technology, which is applied in lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. Compact, easy to operate, the effect of reducing the hazard of lead dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

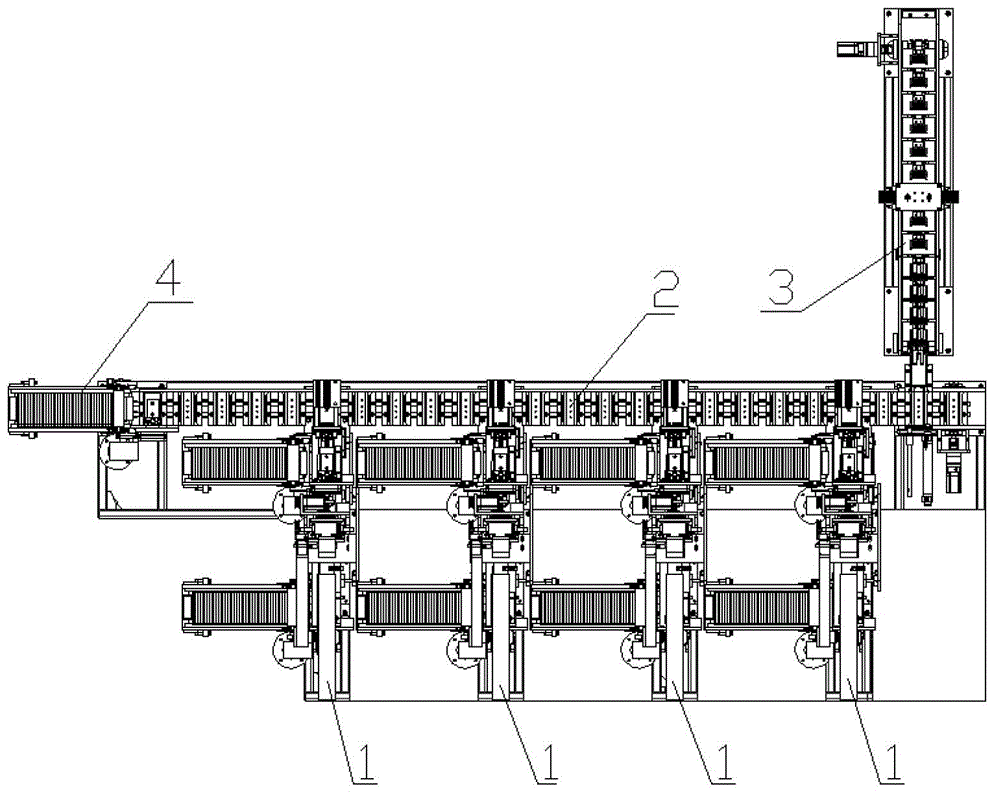

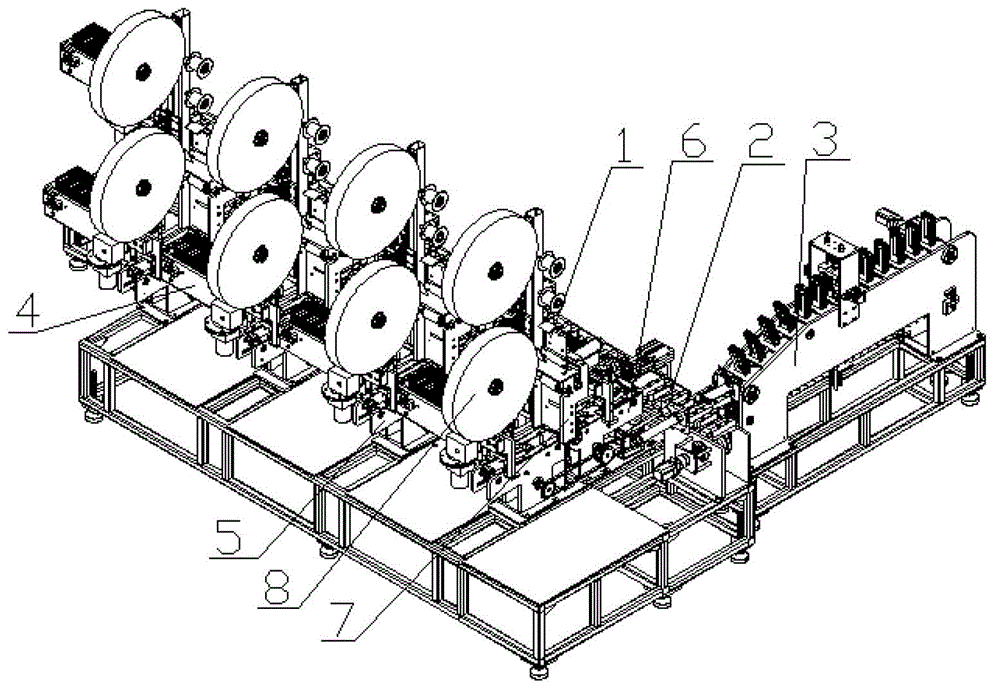

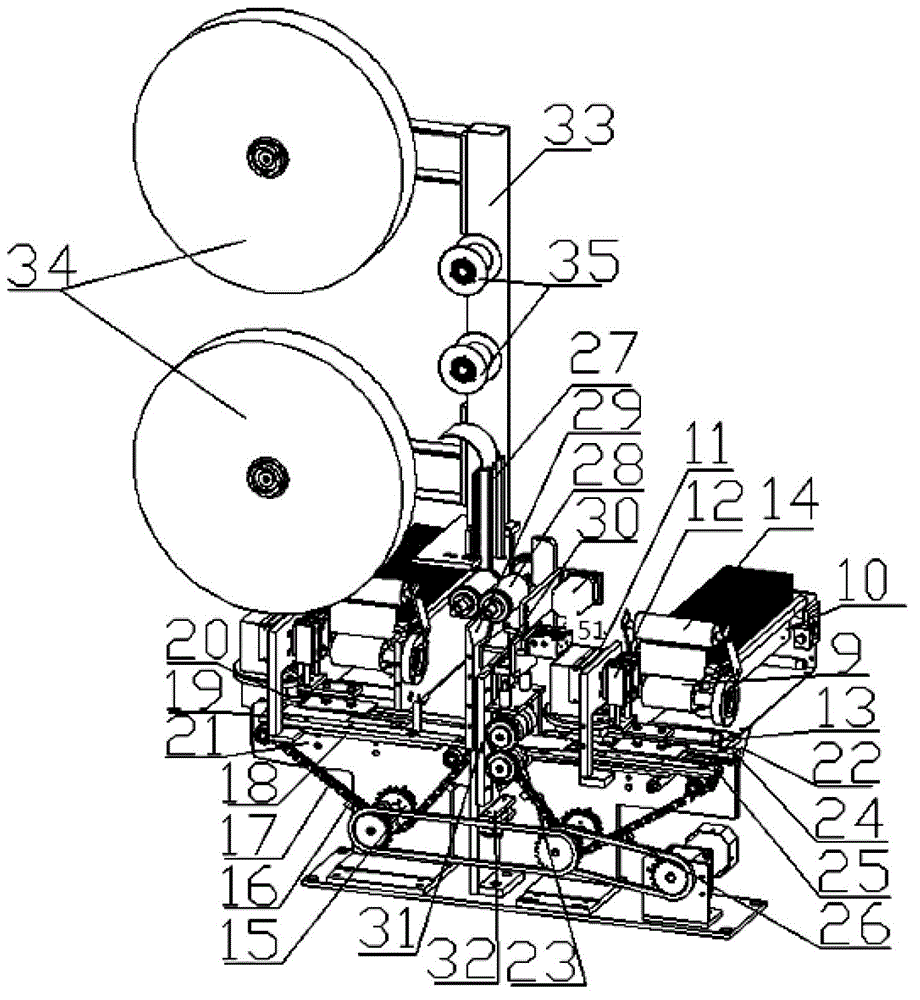

[0026] Embodiment: Take the 5+4 wrapping mechanism as an example

[0027] Such as figure 1 , 2 As shown, in this embodiment, a parallel wrapping mechanism for battery pole plates includes as a whole: a pole plate feeding mechanism 4 for providing the first pole plate, and a spaced stacking of the first pole plate and the second plate after wrapping is realized. It is composed of an independent conveying mechanism 1 installed as a wrapping group, a stacking mechanism 2 for realizing 5+4 clusters, and an erecting mechanism 3 for erecting and sorting the clusters. Wherein, the lamination mechanism 2 is a long and narrow channel formed by a chain, and a pole plate feeding mechanism 4 is arranged at the front end to provide the first pole plate, and four independent conveying mechanisms 1 are arranged at equal intervals on the side of the channel. The heights of the four independent conveying mechanisms 1 have an equidistant drop in sequence (the drop is determined by the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com