Antistatic fiber fabric and production method thereof

A technology of antistatic fiber and antistatic agent, which is applied in the field of antistatic fiber fabrics and its preparation, can solve the problems of using single, composite fabrics without antistatic and antioxidation, and without preparation methods, so as to achieve high production efficiency and improve various In terms of performance, the effect of product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

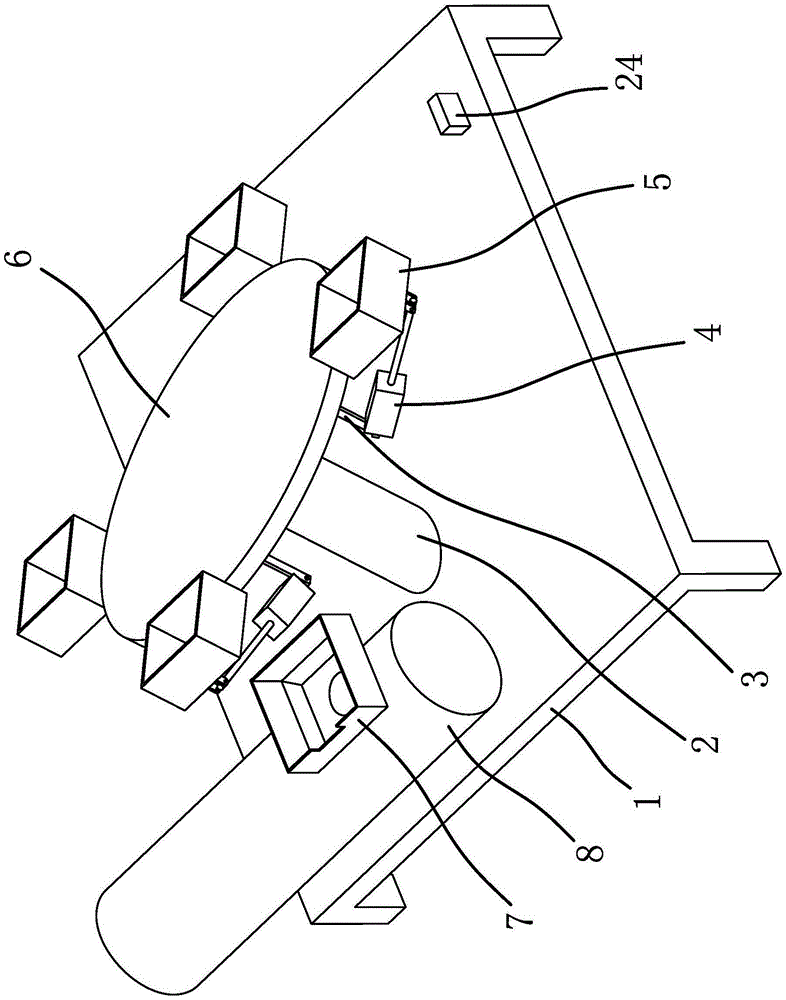

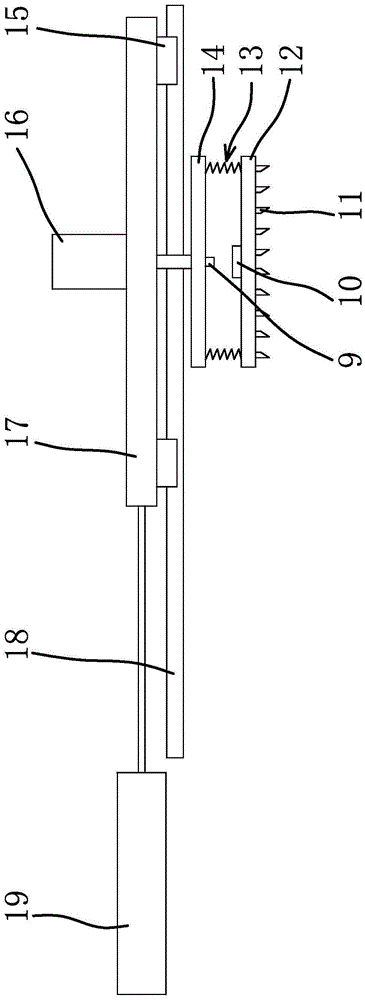

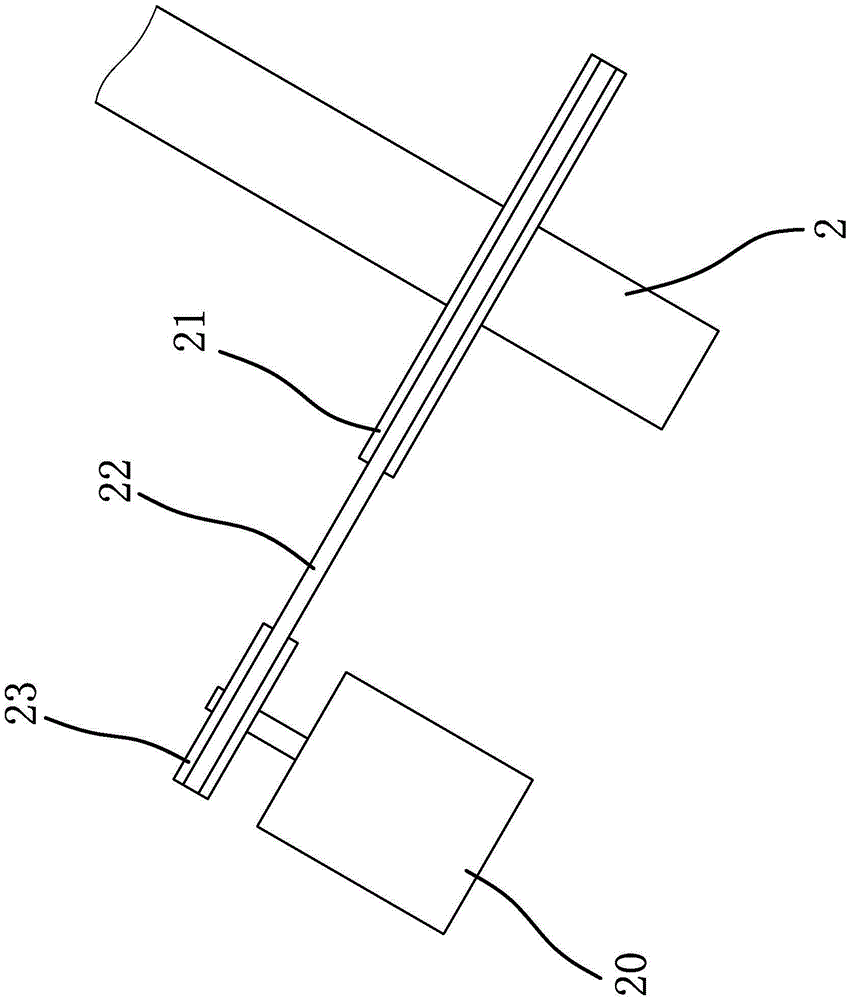

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0040] The antistatic fiber fabric comprises a base fabric layer, on which there is a protective layer, and the protective layer is composed of the following components by weight: 30-50 parts of polyvinyl chloride resin, 1.8-3.6 parts of azodicarbonamide, talc 7 to 8 parts of powder, 1.6 to 4.8 parts of white oil, 6 to 12 parts of antistatic agent, 2 to 4 parts of light stabilizer, 1 to 3 parts of antioxidant and 0.8 to 2.4 parts of plasticizer; in this embodiment , the antistatic agent adopts anionic antistatic agent, the light stabilizer adopts light stabilizer 622, the antioxidant adopts antioxidant DLTP, and the plasticizer adopts liquid plasticizer; The main ingredients are added with an appropriate amount of azodicarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com