Automatic gas-liquid separation device and method for chlorine dioxide generator under high negative pressure environment

A chlorine dioxide, gas-liquid separation technology, applied in the direction of separation methods, chemical instruments and methods, chlorine oxide, etc., can solve problems such as failure to use normally, residual liquid cannot be discharged by itself, and restrictions on the promotion and application of chlorine dioxide, etc., to achieve The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

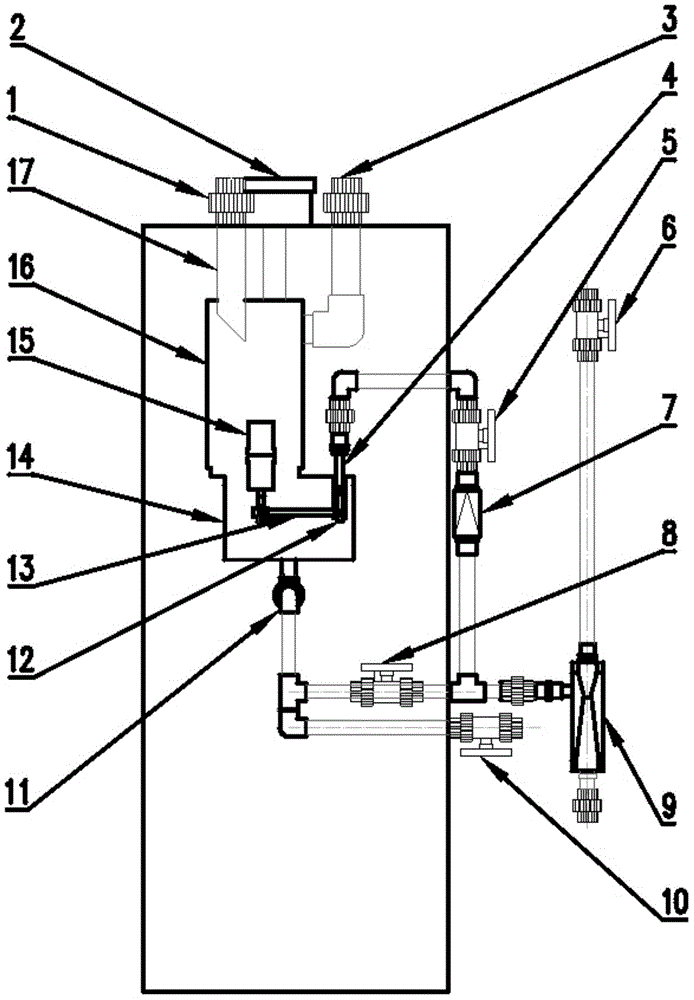

[0024] As shown in the figure, the present invention includes a housing, an automatic gas-liquid separation system and a residual liquid discharge system.

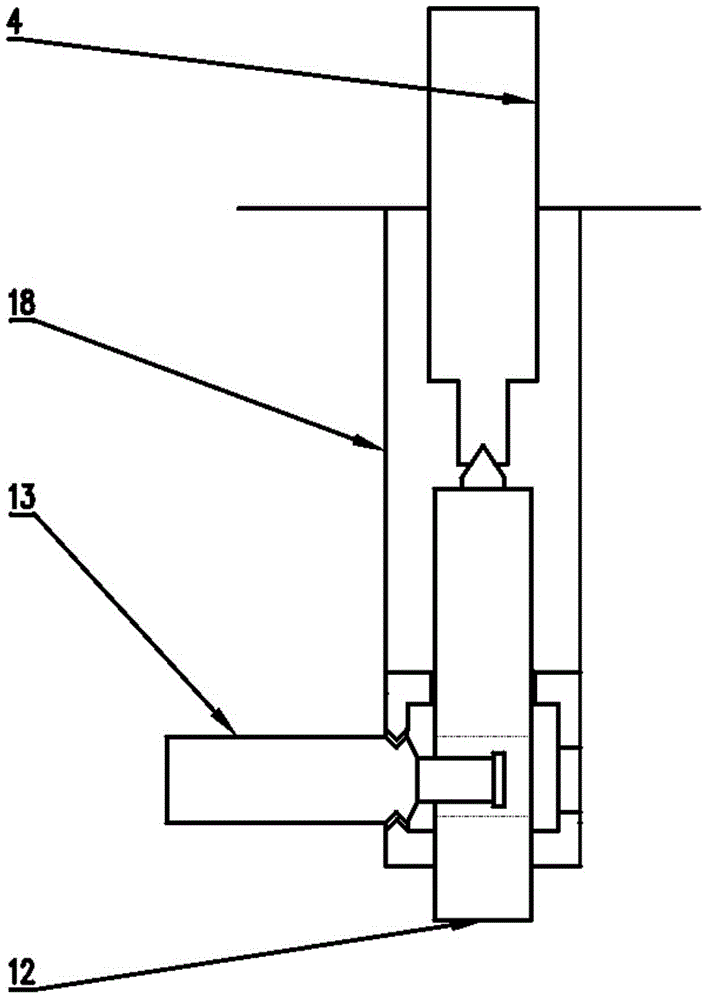

[0025] The gas-liquid automatic separation system includes a gas-liquid mixture inlet 1, an inner tube 17, a gas outlet 3, a separation box 16, a liquid collection box 14, a float 15, a linkage rod 13, a sealing cone 12 and a liquid outlet pipe 4; The liquid mixture is connected to the inlet of the upper part of the separation box 16, the upper part of the separation box 16 is provided with an air outlet 3, the separation box 16 communicates with the liquid collection tank 14, and the float 15 controls the sealing cone 12 to connect with the outlet pipe 4 through the linkage rod 13. The fulcrum of the linkage rod 13 is fixed on the sealing support 18; the sealing support 18 is fixed on the top of the liquid collection tank 14, and the bottom of the liquid collection tank is provided with a sewage outlet 11 and a sewage disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com