Needleless electrostatic spinning device

An electrospinning, needle-free technology, which is applied in the direction of electrospinning, textiles and papermaking, filament/thread forming, etc., can solve the problems of incapable polymer solution electrospinning, easy clogging of needles, and difficulty in cleaning, etc., and achieves improvement The effect of spinning efficiency, avoiding mutual interference, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

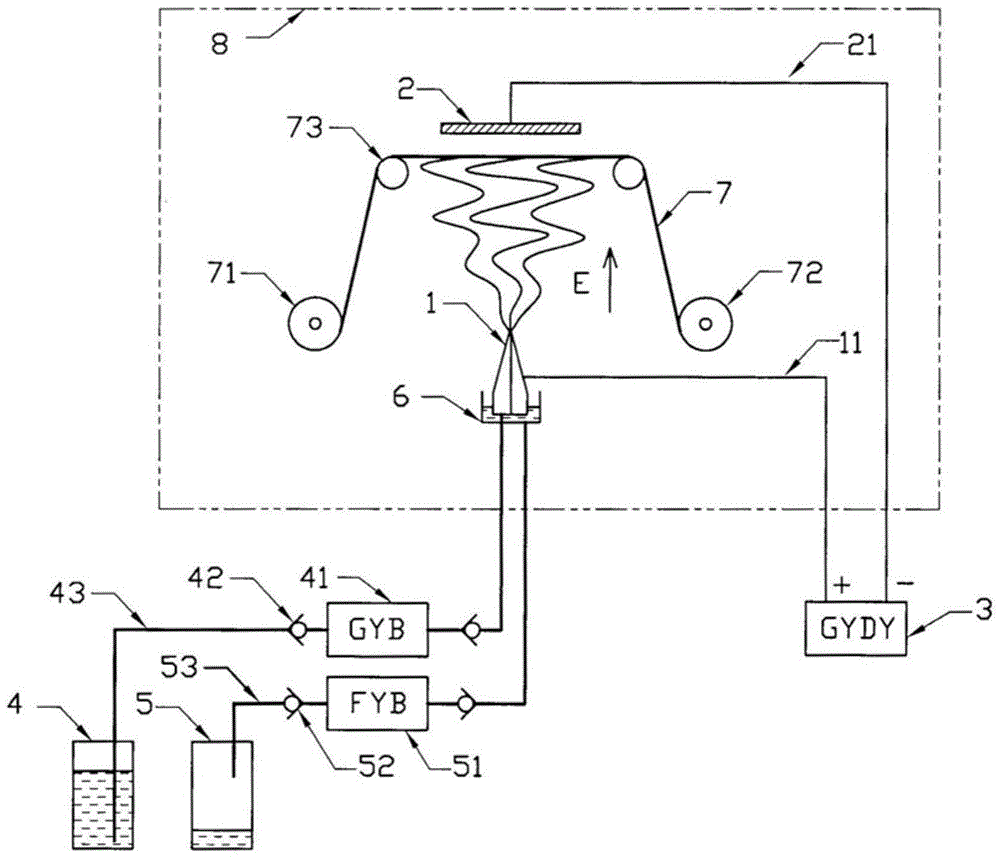

[0041] exist figure 1 The configuration of the needle-free electrospinning device for electrospinning a polymer solution according to the present invention is shown in . It consists of a slit-type spinneret 1, a receiving electrode 2, a high-voltage power supply GYDY (3), a solution tank 4 for storing polymer solutions, a waste liquid tank 6, a substrate 7 and its winding system, etc.

[0042] 1. The slit-type spinneret 1 is connected to the positive pole of the high-voltage power supply 3 through the positive pole high-voltage cable 11; the high-voltage power supply 3 provides the positive pole high voltage.

[0043] The receiving electrode 2 located directly above the spinneret is connected to the negative pole of the high voltage power supply 3 through the negative high voltage cable 21; the high voltage power supply 3 provides negative high voltage.

[0044] 2. Storage of polymer solution for electrospinning in solution tank 4 . The solution tank 4 is connected to the sl...

Embodiment 2

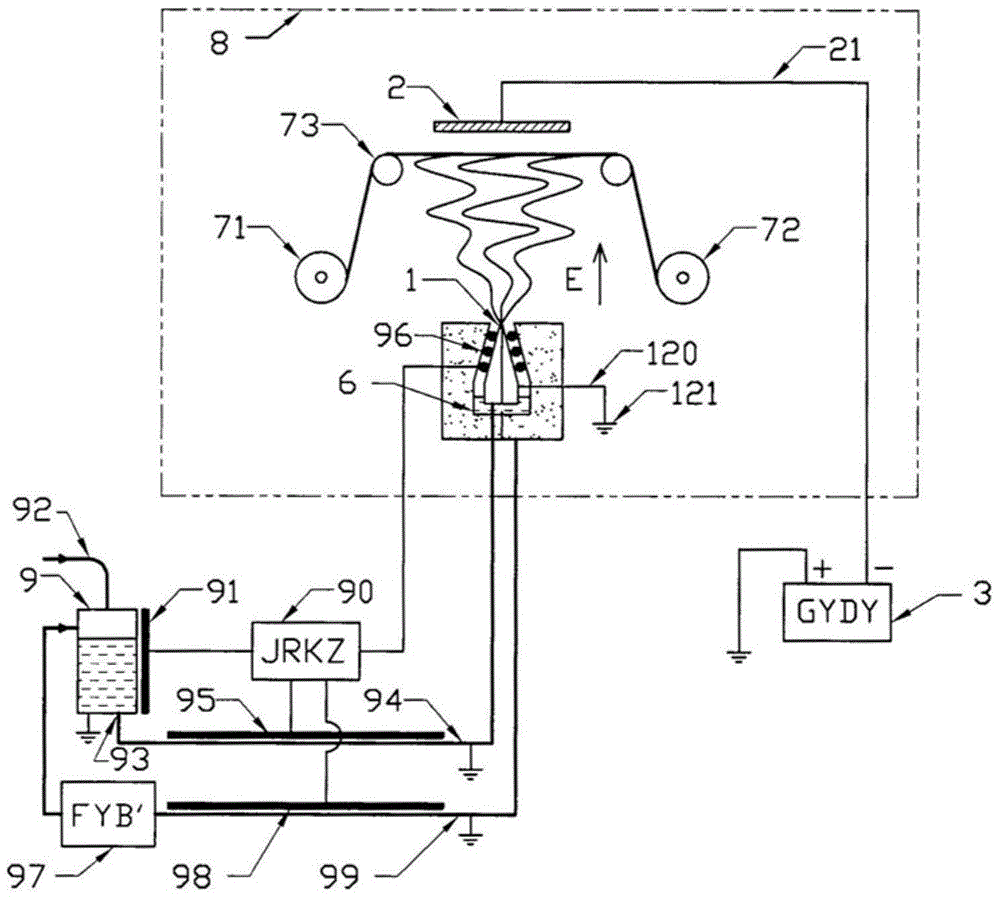

[0085] exist figure 2 The composition of a needle-free electrospinning device for electrospinning polymer melts is shown in . It consists of a slit-type spinneret 1, a receiving electrode 2, a high-voltage power supply GYDY (3), a liquid storage tank 9 for storing polymer melts, a waste liquid tank 6, a substrate 7 and its winding system, and a heating device and Its electric heating control device JRKZ (90) and other components.

[0086] 1. The slit spinneret 1 is connected to the ground 121 through the ground wire 120 . The receiving electrode 2 is connected to the high-voltage power supply GYDY (3) through the negative high-voltage cable 21, and the high-voltage power supply 3 provides negative high voltage.

[0087] 2. The polymer melt used for electrospinning is stored in the liquid storage tank 9 . The top of the liquid storage tank 9 is connected to a compressed air source through a compressed air pipeline 92; the outlet 93 at the bottom of the liquid storage tank 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com