Continuous electrolytic cell for potassium ferrate

A technology of potassium ferrate and electrolyzer, applied in electrolysis process, electrolysis components, cells, etc., can solve the problems of high reaction temperature, affecting production efficiency, low utilization rate, etc., achieve high electrolysis efficiency, improve production efficiency, and scientific design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

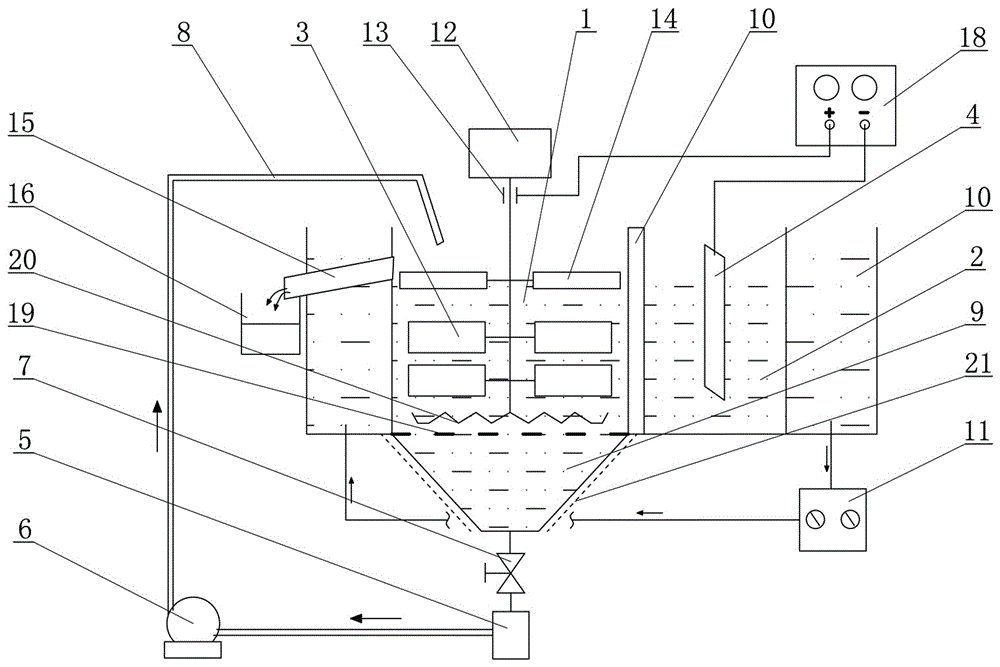

[0027] Such as figure 1 Shown, a kind of potassium ferrate continuous electrolyzer, it comprises electrolyzer and electrolysis electrode, described electrolyzer lower end communicates with sediment collection chamber 9, and described mud collection chamber 9 is connected with sediment bin 5 by valve 7, so The high position of the sedimentation bin 5 communicates with the electrolytic cell through a return pipe 8 , and the return pipe 8 is provided with return power by a circulation pump 6 .

[0028] This part realizes the automatic cleaning of the sludge. After the sludge has accumulated to a certain extent in the sludge collection chamber 9, the valve 7 is opened, and the sludge enters the sludge bin 5 to clarify the electrolyte. The clarified electrolyte plays a role in the circulating pump 6. Down flow back into the electrolytic cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com