Red jujube pick-up machine

A technology for picking machines and red dates, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low degree of automation, time-consuming, time-consuming and labor-intensive, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

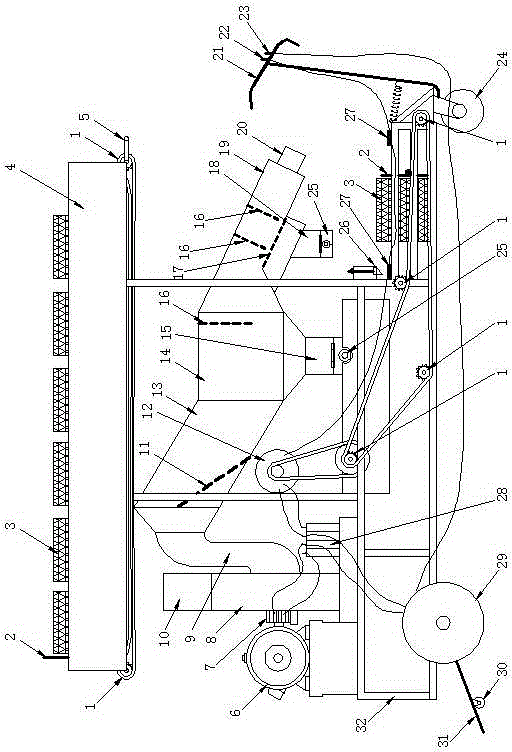

[0024] Embodiment 1: as figure 1 As shown, the jujube picking machine has a frame 32, the front end of the bottom of the frame 32 is provided with a direction wheel 24 and an operating handle 21, the bottom rear end is provided with a walking wheel 29 driven by a motor, and the operating handle 21 is provided with a walking control button 23 The frame 32 is provided with the storage battery 28 that provides electric energy for the traveling wheel 29 driving motors; the frame 32 bottom is provided with the support 31 that places the collection basket 3, and the frame 32 top is provided with a jujube suction container; the jujube suction container is divided into front, The middle and rear three chambers 19, 14, 13, the front chamber 19 has a smaller diameter and is inclined backward and upward, and is provided with a suction tube connection part 20; the middle chamber 14 has a larger diameter and a lower jujube chamber 15 in the lower part , the lower jujube cavity 15 has an ob...

Embodiment 2

[0027] Embodiment 2: On the basis of Embodiment 1, this embodiment further improves the cleaning structure.

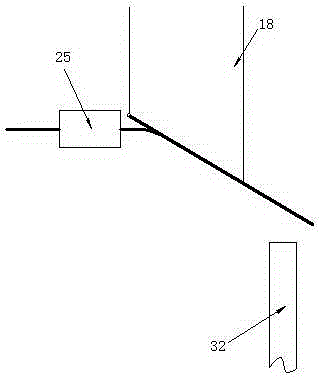

[0028] Specifically, such as image 3 As shown, the bottom of the front section chamber 19 is provided with a cleaning grid 17, and the cleaning grid 17 is provided with a cleaning chamber 18, and the cleaning chamber 18 has an oblique cleaning port, and the cleaning port is provided with an extension frame The counterweight door 25 of 32 sides. When jujube and sundries were inhaled, sundries fell into the cleaning chamber through cleaning grid plate 17, and sundries overcome counterweight door 25 and slide to frame 32 outsides.

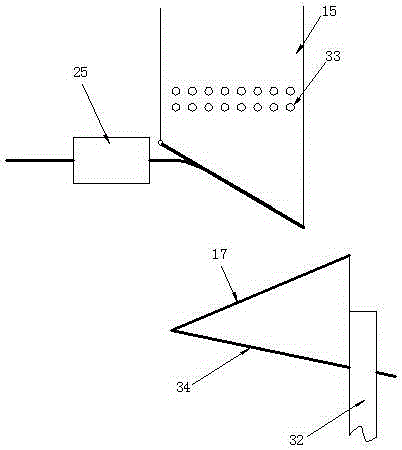

[0029] Such as figure 2 Shown, be provided with the slant plate that makes red jujube slide to collection basket 3 below the lower jujube mouth, slant plate is cleaning grate 17, and the cleaning grate 17 below is provided with the cleaning that makes sundry slide to frame 32 sides. plate 34.

[0030] Such as Figure 4-5 As shown, the s...

Embodiment 3

[0031] Embodiment 3: on the basis of embodiment 1 or 2, present embodiment carries out following improvement in order to prevent red jujube from being sucked out by suction blower 8 suction jujube container: figure 1 As shown, the cleaning grid 17 of the front section chamber 19 is provided with two rubber baffles 16, and the top of the middle section chamber 14 is provided with rubber baffles 16; Ramp 11 of section chamber 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com