Automatic guided vehicle (agv) charging method, mobile charging pile, and charging system

A mobile charging pile and automatic guidance technology, applied in transportation and packaging, secondary battery charging/discharging, electric vehicles, etc., can solve the problems of high cost, idle charging piles, inflexibility, etc., and achieve high equipment utilization, Ensure the timeliness of charging and the effect of the connection of the charging interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

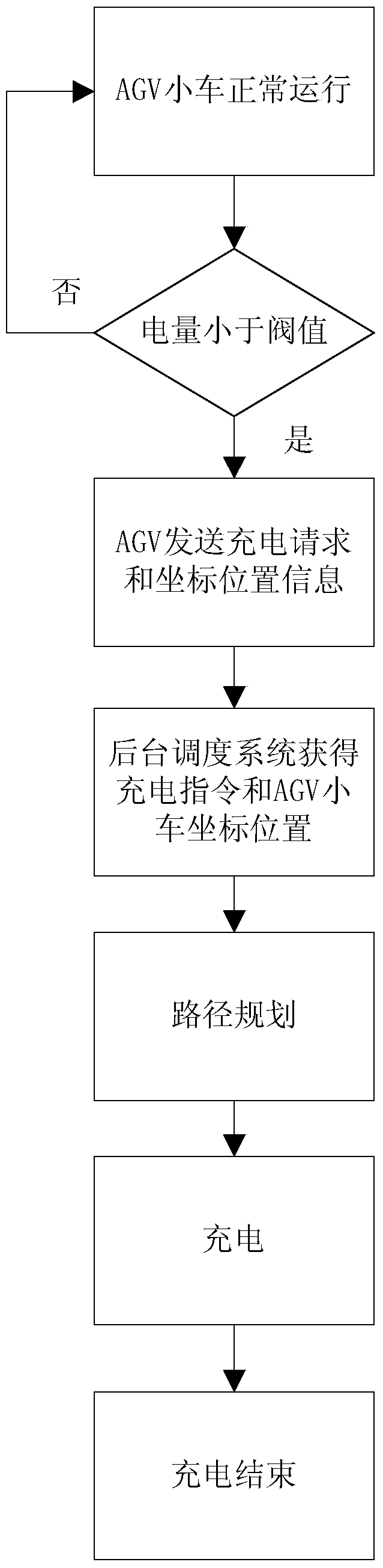

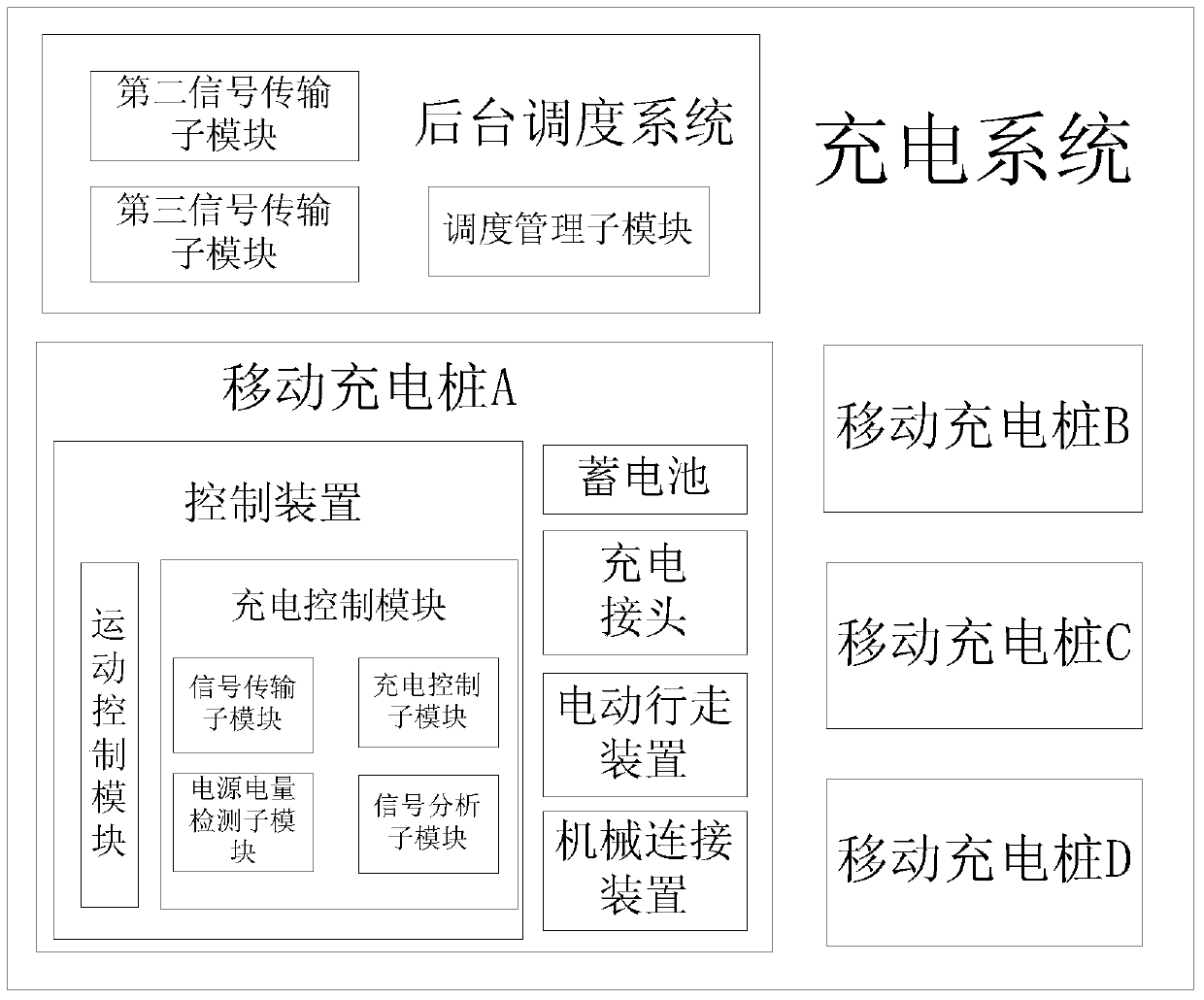

[0032] Refer to attached picture. The charging method of the automatic guided vehicle (AGV) provided by the present invention includes the following steps:

[0033] (1) When the power of the automatic guided vehicle (AGV) is less than the threshold, its control device sends a coordinate position signal with its identity information through the network, and the automatic guided vehicle (AGV) and the mobile charging pile Once the position changes before the connection, its control device will send the new coordinate position with its identity information through the network;

[0034] (2) The mobile charging pile obtains the coordinate position of the charging command and the identity information of the automatic guided vehicle (AGV) that needs to be charged through the background dispatching system;

[0035] (3) The mobile charging pile calculates the route with the automatic guided vehicle (AGV) that needs to be charged through the navigation system, and updates it in real tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com