Shaft seal structure of low temperature pump and sealing gas control system of shaft seal

A cryogenic pump and shaft seal technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, which can solve the problems of unreliable sealing, small molecular weight, easy leakage, etc. , reasonable structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

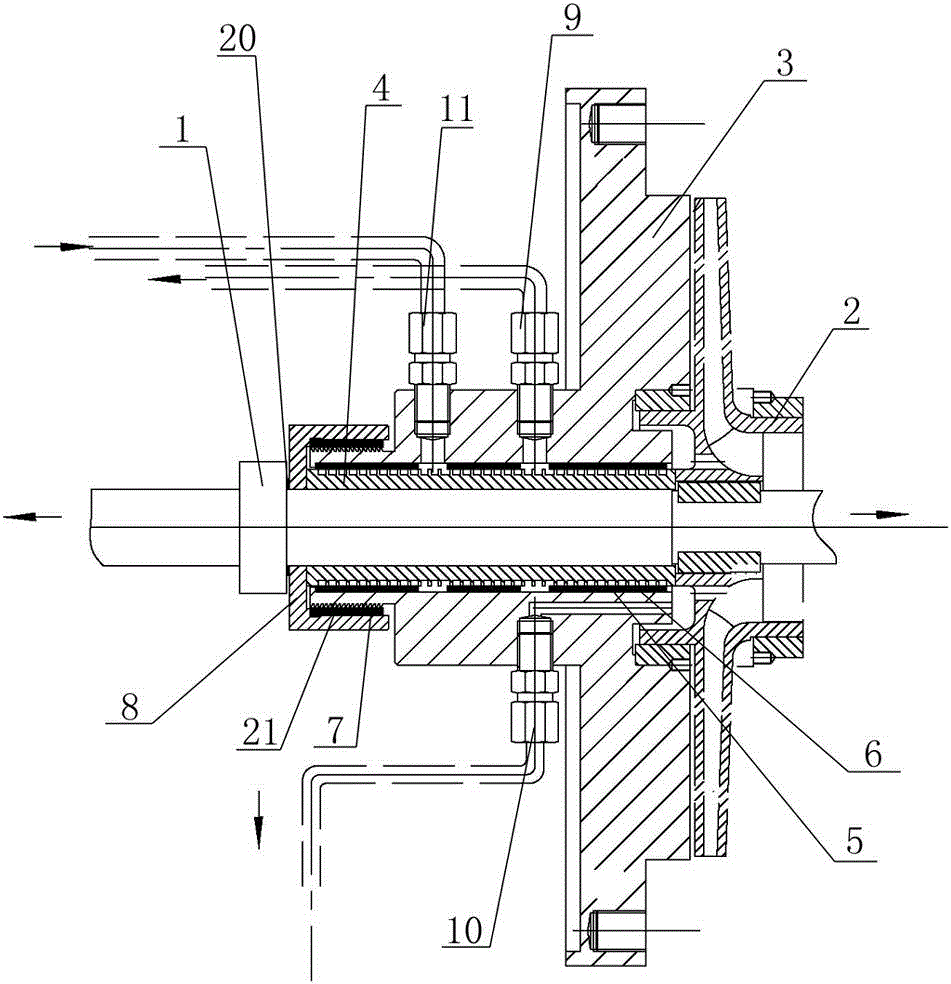

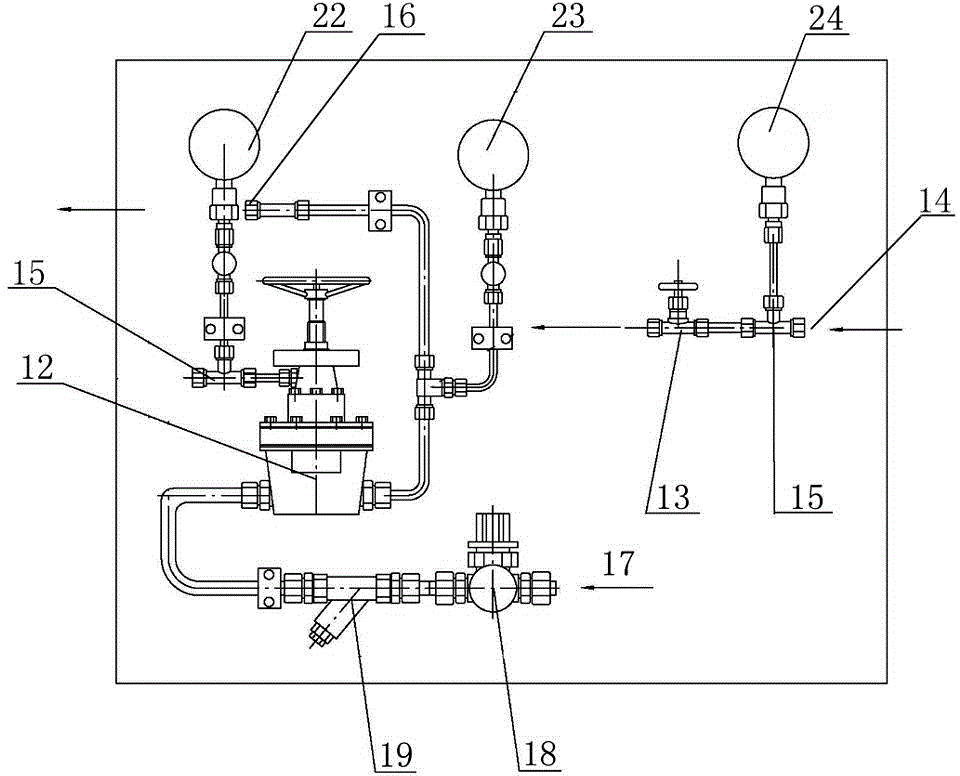

[0012] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the shaft seal structure of the cryopump according to the present invention includes a seal seat 3 which is sleeved on the pump shaft 1 through a shaft hole and is closely attached to the pump body 2, and the seal seat 3 and the pump shaft 1 There is a labyrinth 4 and a first sealing lining 5 which is located outside the labyrinth 4 and is embedded in the shaft hole of the sealing seat. A labyrinth seal pair 6 is formed in cooperation with the seal grooves that run out of the structure due to mutual rotation and running-in; the outer end of the seal seat 3 is provided with a sleeve-type retaining ring 8 with a second seal lining 7; 3 are respectively provided with three air source interfaces communicating with the labyrinth-shaped sealing pair 6, and the three air source interfaces are respectively connected to the mixing air pipe joint 9, the labyrinth u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com