Polycarboxylic acid slump retaining agent modified by phenyl hydroxyl composite ATRP method and preparation method thereof

A technology of phenyl hydroxyl and phenyl hydroxyl block, which is applied in the field of building material concrete admixture, can solve the problem of low sensitivity, and achieve the effect of excellent performance, good adaptability, and gentle reaction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

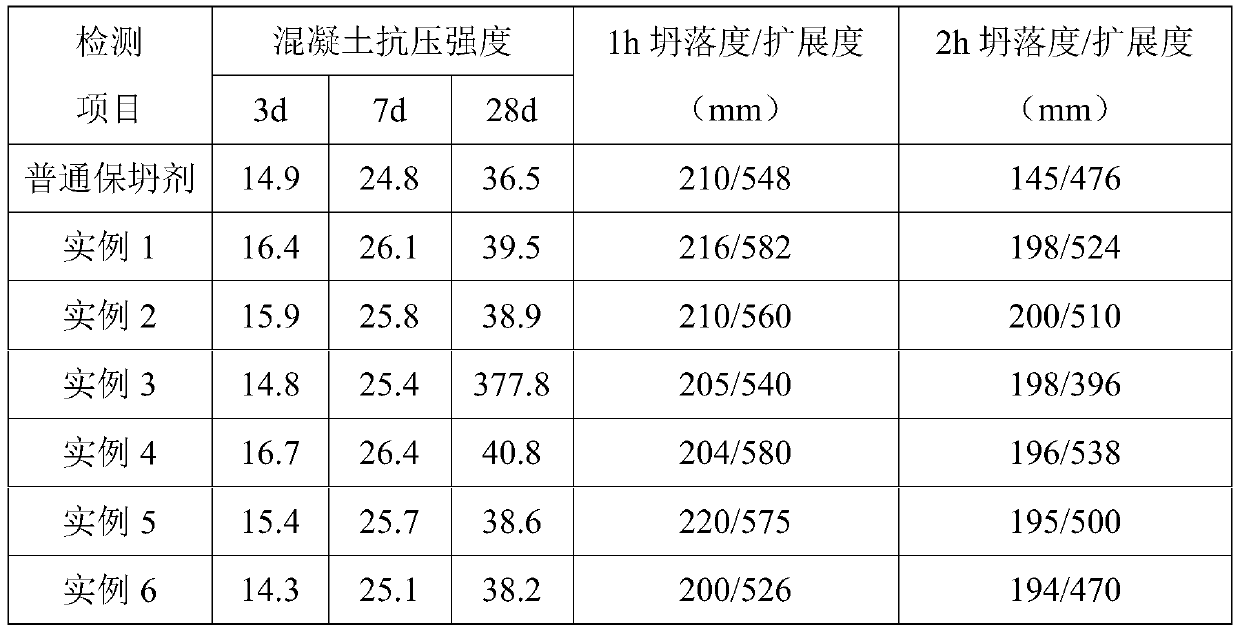

Examples

example 1

[0038] A kind of preparation method of the polycarboxylate slump-retaining agent modified by phenyl hydroxyl composite ATRP method, the total mass of raw material of the present invention is 1000 parts, and mass fraction is 40%, and each component process parameter is as follows:

[0039] Vinyl butyl ether polyoxyethylene ether: 350 parts;

[0040] Hydroxyethyl acrylate: 21 parts;

[0041] Styrene: 9 parts;

[0042] The composition of allyl alcohol and methacryl alcohol with a mass ratio of 1:1: 15 parts;

[0043] N,N,N',N",N'-pentamethacrylate-divinyltriamine: 1.3 parts;

[0044] Cuprous bromide: 0.06 parts;

[0045] Phenylphenol polyoxyethylene ether: 3 parts;

[0046] 1-Bromo-3-methyl-2-butene: 1.6 parts;

[0047] The rest is water.

[0048] Step 1: Mix 9 parts of styrene, 15 parts of a composition of allyl alcohol and methacrylic alcohol with a mass ratio of 1:1, and 1.3 parts of N,N,N',N",N'-pentamethacrylate Add divinyltriamine, 0.06 parts of cuprous bromide, 3 part...

example 2

[0052] A kind of preparation method of the polycarboxylate slump-retaining agent modified by phenyl hydroxyl composite ATRP method, the total mass of raw material of the present invention is 1000 parts, and mass fraction is 40%, and each component process parameter is as follows:

[0053] Vinyl butyl ether polyoxyethylene ether: 348 parts;

[0054] Hydroxypropyl acrylate: 24 parts;

[0055] 1-allyl-4-fluorobenzene: 7 parts;

[0056] Prenol: 14 parts;

[0057] N,N,N',N',N″,N″-hexamethacrylate triethylenetetramine: 1.6 parts;

[0058] Ferrous bromide: 0.04 parts;

[0059] Sodium 2-acrylamide-2,2-dimethylethanesulfonate: 4 parts;

[0060] Methallyl chloride: 1.9 parts;

[0061] The rest is water.

[0062] Step 1: 7 parts of 1-allyl-4-fluorobenzene, 14 parts of isopentenol, 1.6 parts of N,N,N',N',N",N"-hexamethacrylate Add vinyltetramine, 0.04 parts of ferrous bromide, 4 parts of 2-acrylamide-2,2-dimethylethanesulfonate sodium and 300 parts of water into the No. Nitrogen 3...

example 3

[0066] A kind of preparation method of the polycarboxylate slump-retaining agent modified by phenyl hydroxyl composite ATRP method, the total mass of raw material of the present invention is 1000 parts, and mass fraction is 40%, and each component process parameter is as follows:

[0067] Vinyl butyl ether polyoxyethylene ether: 354 parts;

[0068] Composition of hydroxyethyl acrylate and hydroxypropyl acrylate with a mass ratio of 2:1: 18 parts;

[0069] 4-methoxy-2-vinylaniline: 5 parts;

[0070] Methacryl alcohol: 16 parts;

[0071] 2,2,-bipyridine: 0.8 parts;

[0072] Cuprous chloride: 0.02 parts;

[0073] Fatty alcohol polyoxyethylene ethers: 5 parts;

[0074] 2-Bromo-3-methylbutenoic acid methyl ester: 1.4 parts;

[0075] The rest is water.

[0076] Step 1: Mix 5 parts of 4-methoxy-2-vinylaniline, 16 parts of methacryl alcohol, 0.8 part of 2,2,-bipyridyl, 0.02 part of cuprous chloride, 5 parts of fatty alcohol polyoxyethylene ether Add 300 parts of water into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com