A recovery device for cvi/cvd process tail gas

A technology for recovering device and process tail gas, applied in hydrogen/syngas production, nano-carbon, fibrous fillers, etc., can solve the problem of low utilization rate of source gas, achieve easy control of reaction temperature, prolong residence time, and stabilize reaction environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

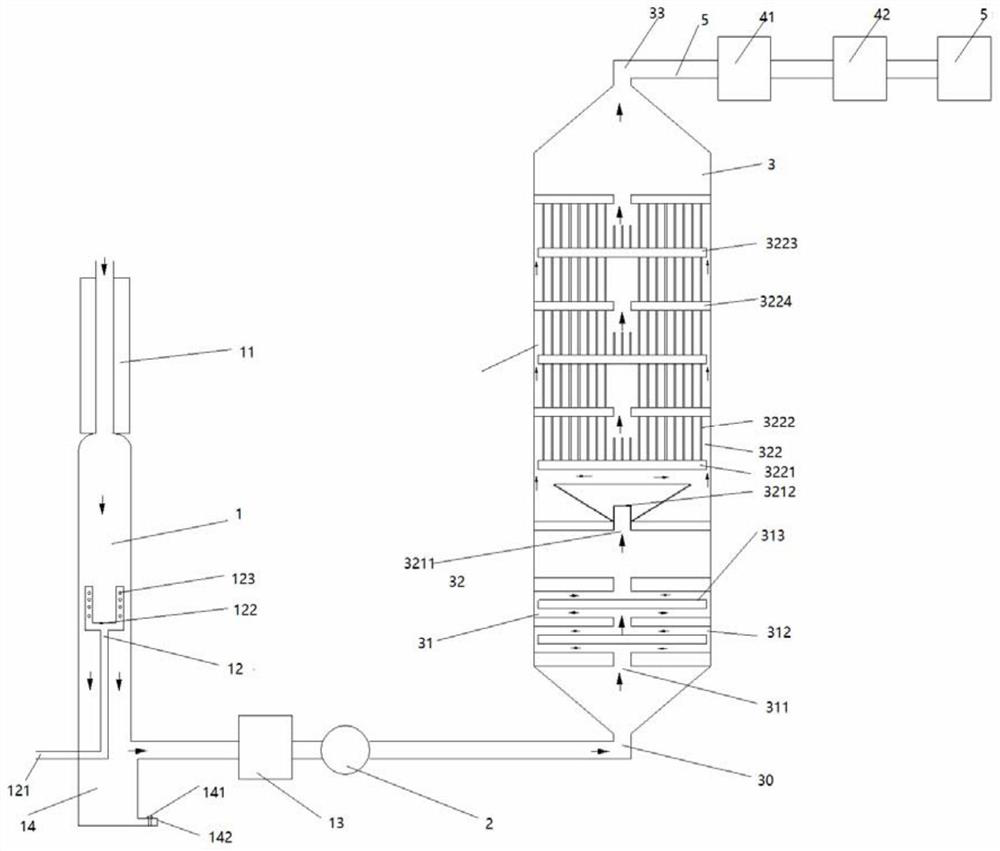

[0030] Such as Figure 1~3 Shown is an embodiment of the present invention,

[0031] (1) Equipment:

[0032] A recovery device for CVI / CVD process tail gas, comprising a cooling filter device 1, a vacuum pump 2, an isothermal cracking furnace 3 and a later comprehensive treatment device 4, the cooling filter device 1 includes a circulating liquid cooling module 11, an oil filter 12 and a drying Filter 13; the cooling and filtering equipment also includes an oil tank 14, which communicates with the oil filter 12, and a butterfly valve 141 and a waste oil outlet 142 are arranged at the end of the oil tank. The vacuum pump 2 is arranged between the cooling filter equipment 1 and the isothermal cracking furnace 3; the bottom of the isothermal cracking furnace 3 is provided with a preheating zone module 31, and an isothermal zone module 32 is arranged above the preheating zone module 31; The hot zone module 31 is a multilayer labyrinth graphite plate 313; the bottom of the isothe...

Embodiment 2

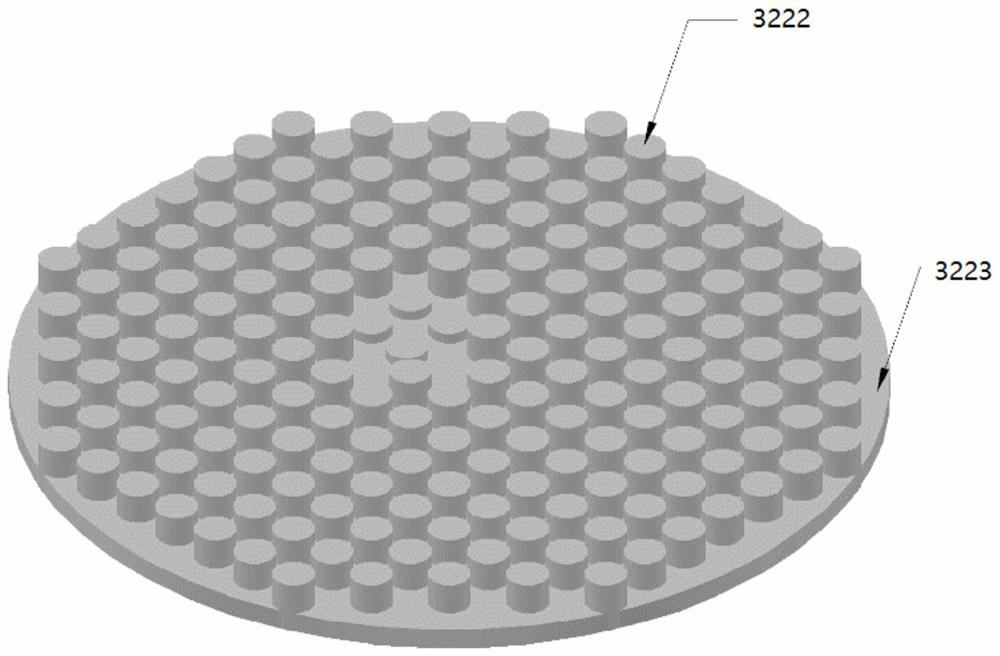

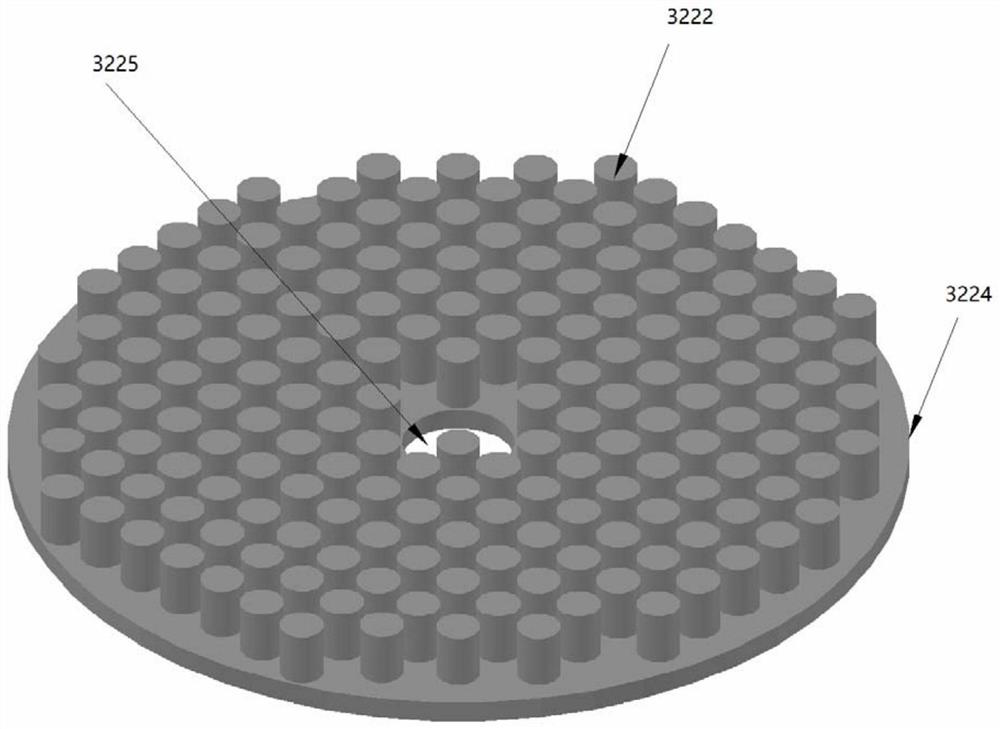

[0041] Such as Figure 4~6 Shown is an embodiment of the present invention,

[0042] (1) Equipment:

[0043] A recovery device for CVI / CVD process tail gas, comprising a cooling filter device 1, a vacuum pump 2, an isothermal cracking furnace 3 and a later comprehensive treatment device 4, the cooling filter device 1 includes a circulating liquid cooling module 11, an oil filter 12 and a drying Filter 13; the cooling and filtering equipment also includes an oil tank 14, which communicates with the oil filter 12, and a butterfly valve 141 and a waste oil outlet 142 are arranged at the end of the oil tank. The vacuum pump 2 is arranged between the cooling filter equipment 1 and the isothermal cracking furnace 3; the bottom of the isothermal cracking furnace 3 is provided with a preheating zone module 31, and an isothermal zone module 32 is arranged above the preheating zone module 31; The hot zone module 31 is a multilayer labyrinth graphite plate 313; the bottom of the isothe...

Embodiment 3

[0052] Such as Figure 7-9 Shown is an embodiment of the present invention,

[0053] (1) Equipment:

[0054] A recovery device for CVI / CVD process tail gas, comprising a cooling filter device 1, a vacuum pump 2, an isothermal cracking furnace 3 and a later comprehensive treatment device 4, the cooling filter device 1 includes a circulating liquid cooling module 11, an oil filter 12 and a drying Filter 13; the cooling and filtering equipment also includes an oil tank 14, which communicates with the oil filter 12, and a butterfly valve 141 and a waste oil outlet 142 are arranged at the end of the oil tank. The vacuum pump 2 is arranged between the cooling filter equipment 1 and the isothermal cracking furnace 3; the bottom of the isothermal cracking furnace 3 is provided with a preheating zone module 31, and an isothermal zone module 32 is arranged above the preheating zone module 31; The hot zone module 31 is a multilayer labyrinth graphite plate 313; the bottom of the isothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com