Patents

Literature

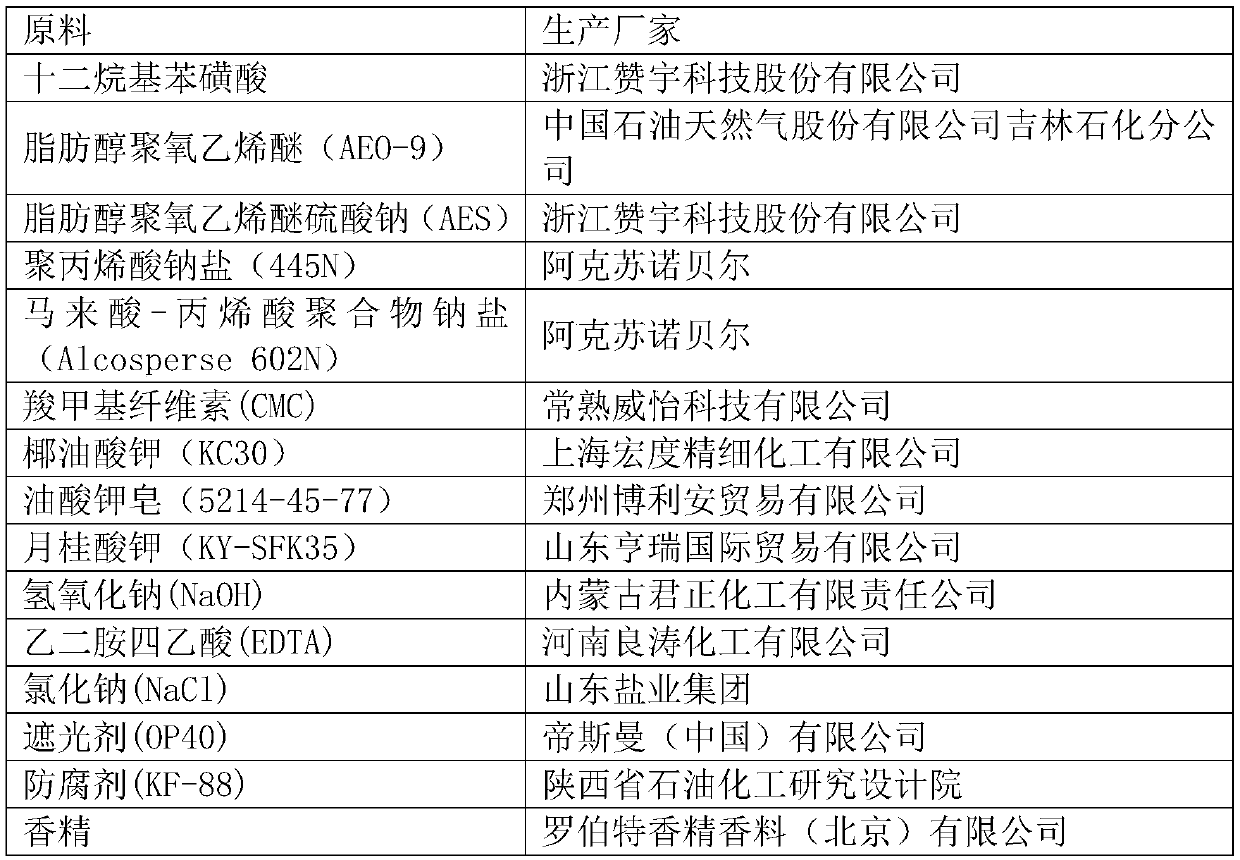

114 results about "Potassium soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium Hydroxide is a type of lye specifically used to make liquid soap. It is also known as potash, lye or even KOH. This is the chemical that induces saponification of the fats and oils to create liquid soap.

Process for separating unsaponifiable valuable products from raw materials

Disclosed are processes for separating valuable products, including unsaponifiable materials, from any given matrix of raw materials that is mainly composed of saponifiable components and unsaponifiable components. Preferred methods include converting sodium or potassium soaps obtained from the saponification of a starting material into metallic soaps which have a lower melting point, and when melted, have viscosity sufficiently low to enable processing such as by distillation / evaporation processes. Preferred raw materials include animal or vegetable products, as well as by-products, residues, and waste products from the processing of animal or vegetable products, such as from food processing, cellulose processing and the like. Valuable products which may be obtained by the disclosed processes include sterols, vitamins, flavonoids, and tocopherols.

Owner:RESITEC PARTICIPACOES

Natural laundry soaps

ActiveUS20170121641A1Good synergyAid removalInorganic/elemental detergent compounding agentsSoap detergents with organic compounding agentsNatural productPotassium

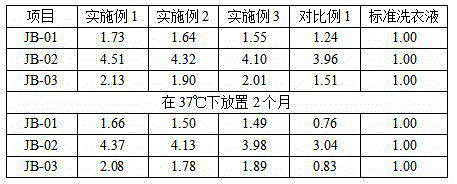

A series of natural soaps, both liquid and solid, and methods of making thereof, which have a synergistic effect when formulated with anti-redeposition ingredients in laundry applications both in synthetic and natural textiles and fabrics. The fatty acids and / or natural oils based series of natural soaps include both sodium and potassium soap products that interact synergistically with, preferably, known, natural anti-redeposition agents and alkaline builders creating highly effective, natural solid (bar or powdered) and liquid laundry cleaning products. Solid forms soaps are dried to an acceptable amount of moisture content for milling. Further blending is then performed with various natural anti-redeposition agents or natural products which exhibit said characteristics and / or alkaline builders. The solid forms may be formed into single dose tablets. Effervescent additives may further be included.

Owner:VANGUARD SOAP LLC

Process for separating unsaponifiable valuable products from raw materials

InactiveUS6846941B2Fatty oils/acids recovery from wasteFatty acids production/refiningDistillationEvaporation

Disclosed are processes for separating valuable products, including unsaponifiable materials, from any given matrix of raw materials that is mainly composed of saponifiable components and unsaponifiable components. Preferred methods include converting sodium or potassium soaps obtained from the saponification of a starting material into metallic soaps which have a lower melting point, and when melted, have viscosity sufficiently low to enable processing such as by distillation evaporation processes. Preferred raw materials include animal or vegetable products, as well as by-products, residues, and waste products from the processing of animal or vegetable products, such as from food processing, cellulose processing and the like. Valuable products which may be obtained by the disclosed processes include sterols, vitamins, flavonoids, and tocopherols.

Owner:RESITEC PARTICIPACOES

Anti-tritium glove and preparation method thereof

The invention provides an anti-tritium glove and a preparation method thereof. Compound latex adopted for the anti-tritium glove is prepared from, by weight, 200 parts of butyl rubber emulsion, 0.10-0.25 part of polyoxyethylated castor oil, 0-5 parts of potassium hydroxide and 20 parts of dispersoid. The butyl rubber emulsion is prepared from, by weight, 160 parts of butyl rubber, 1.0-1.5 parts of oleic acid, 4.0-7.2 parts of potassium hydroxide, 5.5-6.4 parts of monopotassium phosphate, 35-50 parts of polyvinyl alcohol, 0.8-1.0 part of polyoxyethylene castor oil potassium soap and 94-100 parts of soft water. The dispersoid is prepared from, by weight, 4 parts of sulphur, 5 parts of accelerant Px, 10 parts of accelerant ZDC, 8 parts of zinc oxide, 2 parts of antiager DBH, 0.4 part of green pigment, 5 parts of dispersant NF, 0.8 part of stabilizer KOH, 0.1 part of carbon black, 1.5-5.0 parts of anti-tritium material and 50 parts of water. Compared with the prior art, the anti-tritium glove has the advantages that the tritium permeability coefficient, air tightness, mechanical performance, hot air aging resistance, sulfuric acid solution resistance and sodium hydroxide solution resistance are excellent, and the requirements of relevant military units are met.

Owner:GUANGZHOU DOUBLE ONE LATEX PROD CO LTD

Long-acting bacteriostatic washing soap liquid and preparation method thereof

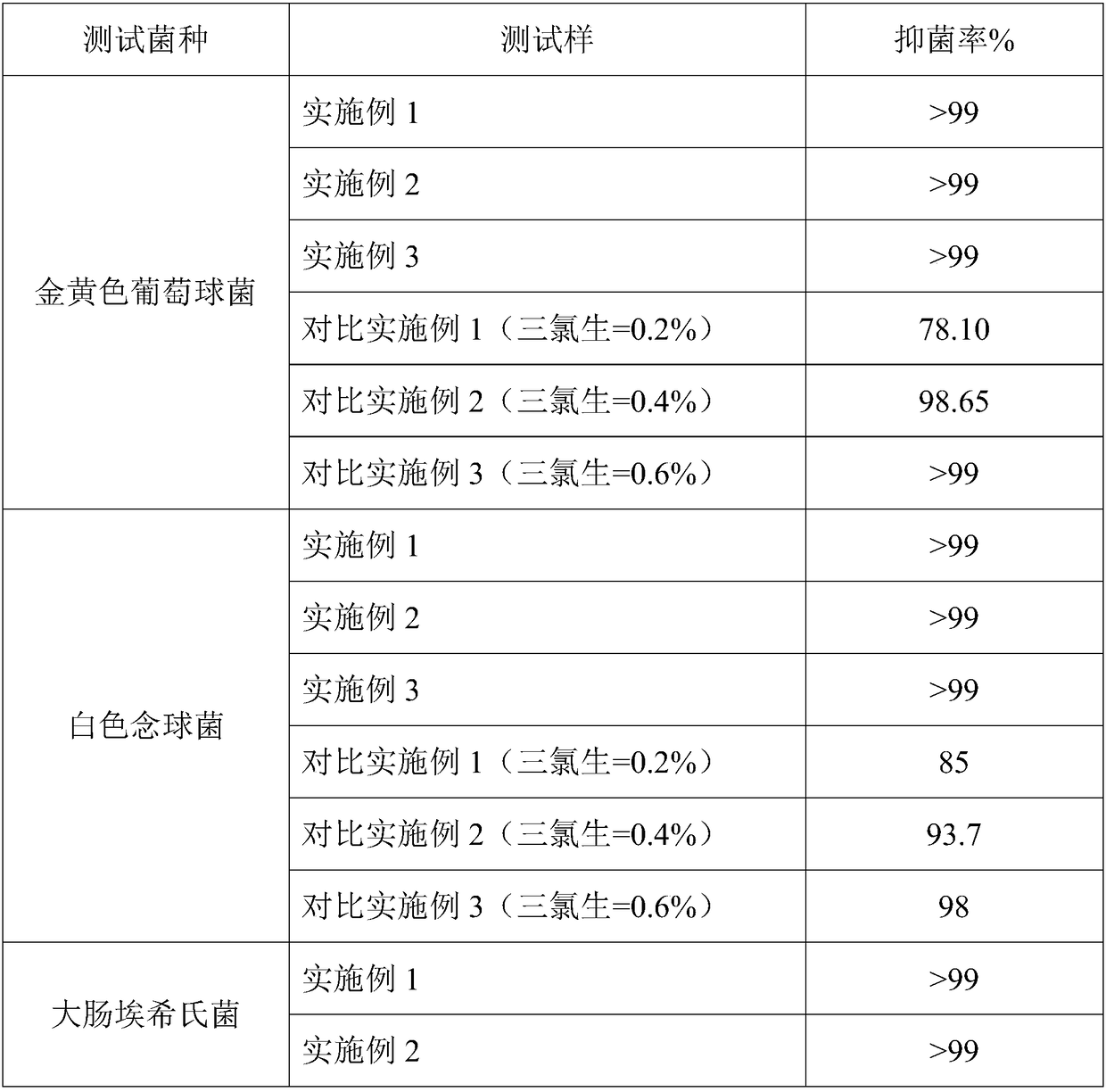

ActiveCN109181914AImprove stabilityAvoid influenceSurface-active non-soap compounds and soap mixture detergentsAmpholytes/electroneutral surface-active compoundsTetrasodium glutamate diacetateWormwood extract

The invention provides a long-acting bacteriostatic washing soap liquid which is prepared from the following components in percent by weight: 3-5% of a potassium aliphatate soap, 10-13.5% of fatty alcohol-polyoxyethylene ether sodium sulfate, 5-7% of fatty alcohol-polyoxyethylene ether, 4-6% of cocoalkanoylamido propyl betaine, 1.5-2.5% of sodium polyacrylate, 0.2-0.3% of protease, 2-3% of propylene glycol, 0.5-1.5% of tetrasodium glutamate diacetate, 0.20-0.35% of silver ions, 0.1-0.3% of wormwood extract, 1-2% of a vinyl pyrrolidone-vinyl imidazole copolymer, 0.5-2.2% of citric acid, 0.1-1%of a thickener, 0.05-0.2% of a preservative, 0.3-0.6% of essence and the balance deionized water. The long-acting bacteriostatic washing soap liquid provided by the invention still plays a sterilizingand bacteriostatic role to a washed fabric and is excellent in decontaminating effect. The invention also provides a preparation method of the long-acting bacteriostatic washing soap liquid.

Owner:中山市妙洁精细化工有限公司

Agricultural extraction products and processes

InactiveUS20080124443A1Fatty oils/acids recovery from wasteInorganic/elemental detergent compounding agentsHigh sodiumFish oil

The inventive developments disclosed in this application include the following features and combinations thereof: extracting oil from spent bleaching earths for animal feed; using earths and acid water as soil amendment / fertilizer; efficient extraction of substances valuable to plants, animals, and humans from plant, animal, and fish oil soapstock, especially using the “interphase” emulsion from soapstock acidulation; use of “black paste” from oil refining as fertilizer component (nutrient source); use of interphase from agricultural oil refining, especially refining of non-degummed oils, as animal feed; use of “oil refining by-products to fertilizers” process and / or KOH refining in conjunction with “Miscella”-type hexane refining or “Zenith” process refining; fertilizers containing silica / silicates from by-products of agricultural oil refining; use of higher-sodium oil refining by-products as fertilizer for sodium-tolerant plants; using by-products of sugar beet refining as nutrient source; agriculturally useful potassium soaps from oil refining; products of the refining of non-degummed agricultural oils having useful biocidal or other biological properties; the use, as a feed additive, of potassium soapstock from the caustic refining of agricultural oils using a potassium caustic (KOH), especially with non-degummed oils, which has unexpected advantages over the use of soapstock from sodium caustic (NaOH) refining, especially from degummed oils.

Owner:DANIELS AGROSCI

Color-adsorbing laundry sheet and manufacturing method thereof

InactiveCN106281819AImprove adsorption capacityCause secondary pollutionNon-ionic surface-active compoundsDetergent mixture composition preparationLauryl ether sulfatePotassium

The invention discloses a color-adsorbing laundry sheet and a manufacturing method thereof and belongs to the technical field of washing products and manufacturing methods. The color-adsorbing laundry sheet comprises a color-adsorbing cloth body and is characterized in that a clothes-washing substance layer is attached to the color-adsorbing cloth body and comprises, by weight, 50-60 parts of deionized water, 2-8 parts of lauryl sodium sulfate, 1-5 parts of C12-14 alkyl glycoside, 0.05-0.2 part of ethylene diamine tetraacetic acid disodium, 5-15 parts of ammonium lauryl ether sulfate, 5-10 parts of sodium alpha-olefin sulfonate, 1-5 parts of isomeric alcohol ethoxylates, 1-5 parts of coconut fatty acid diethanol amide, 1-5 parts of potassium soap base, 0.5-2.5 parts of sodium polyacrylate, 1-5 parts of penetrating agent, 1-10 parts of cocoamido propyl hydroxy sulfobetaine, 0.05-0.5 part of preservative, 0.1-0.5 part of citric acid, 0.1-0.8 part of essence and 2-10 parts of DFE. The color-adsorbing cloth is used as a carrier, is high in tensile strength and not prone to damage, and can effectively adsorb faded colors in the washing process of clothes.

Owner:冯鲜花

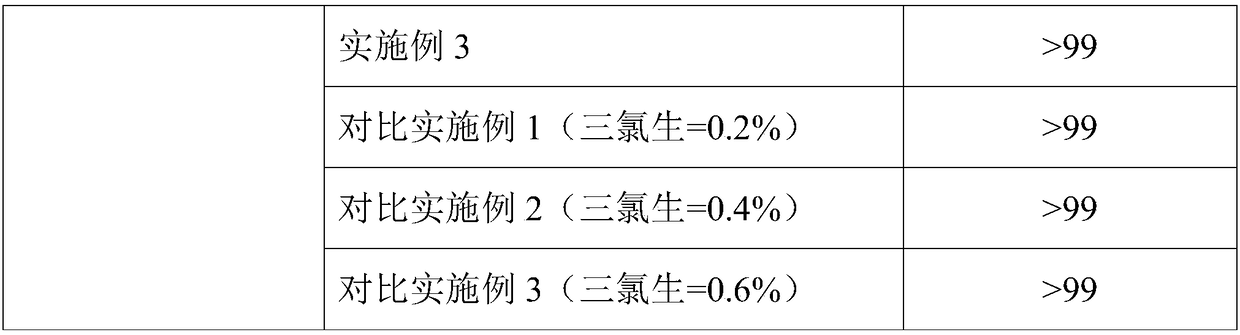

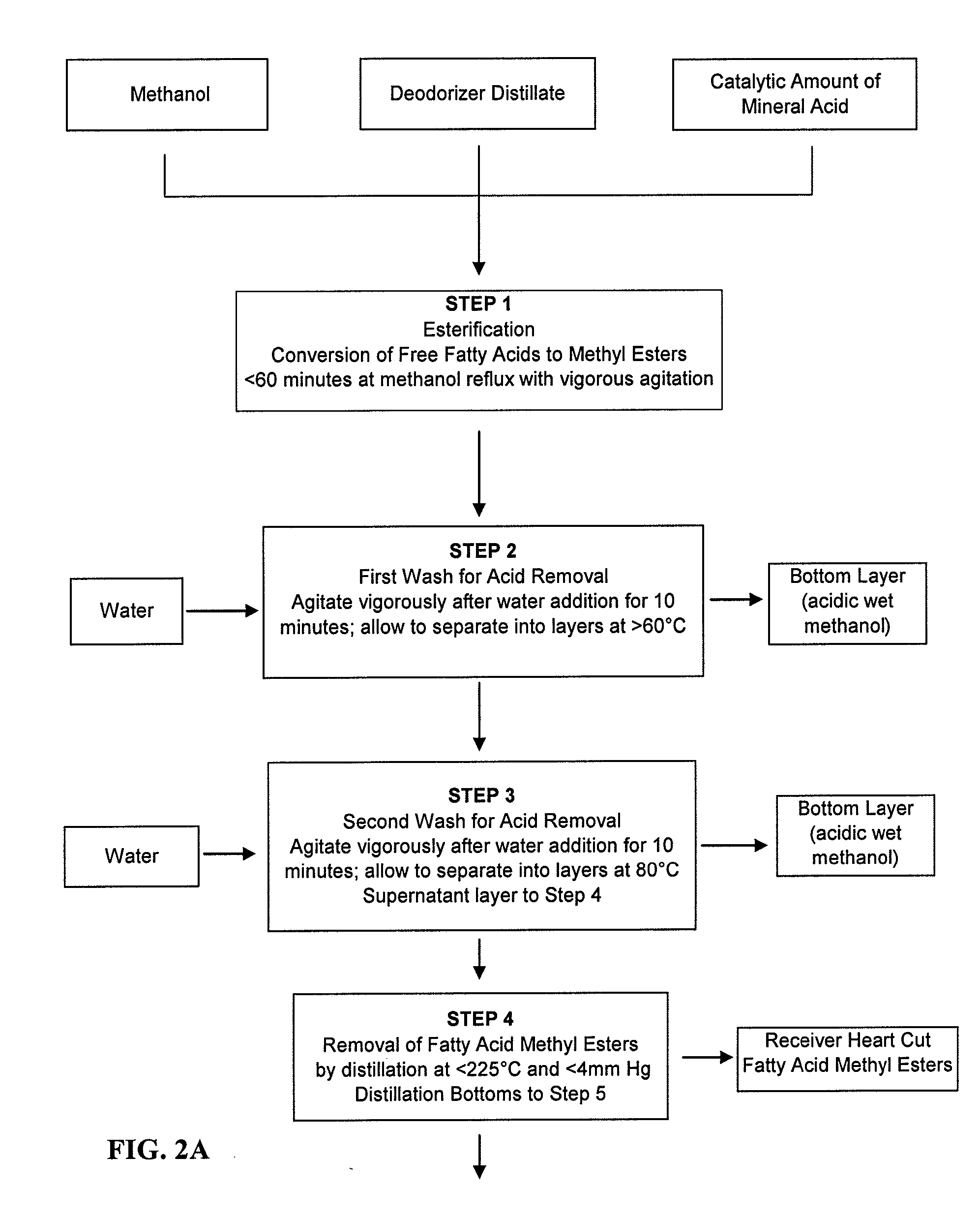

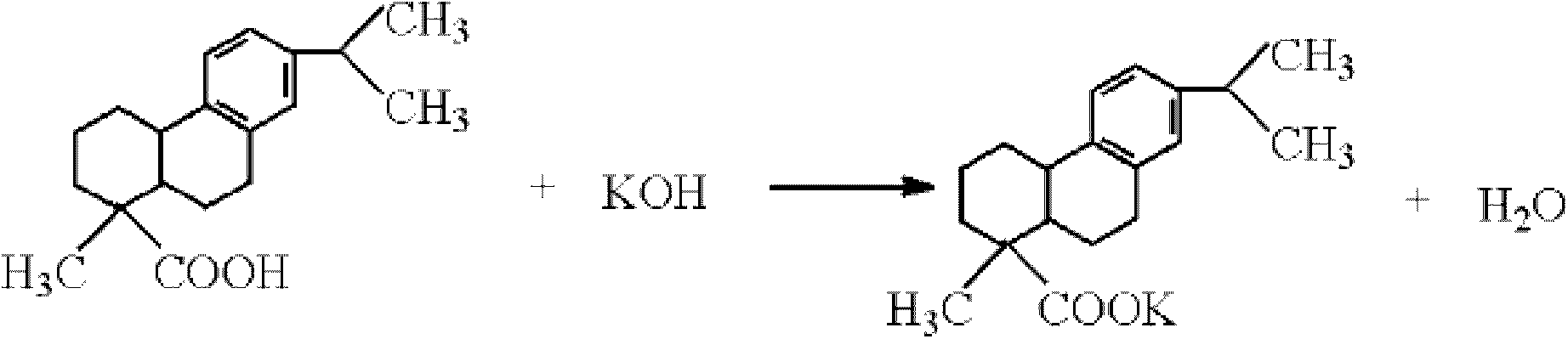

Process for isolating phytosterols and tocopherols from deodorizer distillate

InactiveUS20080015367A1Easy to handleFatty acid esterificationFatty acids production/refiningPlant sterolDistillation

A process is described for efficiently recovering at least one of phytosterols and tocopherols in substantially pure form from the deodorizer distillates that may be obtained as by-products of the refining of edible oils. The phytosterol fatty acid esters present in deodorizer distillate are saponified with potassium hydroxide in a solvent medium containing methanol and water, thereby forming a solvent medium containing methanol, water, and the potassium soaps of fatty acids. Unsaponiable matter including tocopherols remain dissolved in this medium, allowing recovery of substantially pure phytosterols. Tocopherols in substantially pure form may be recovered by distillation under reduced pressure.

Owner:WILEY ORGANICS

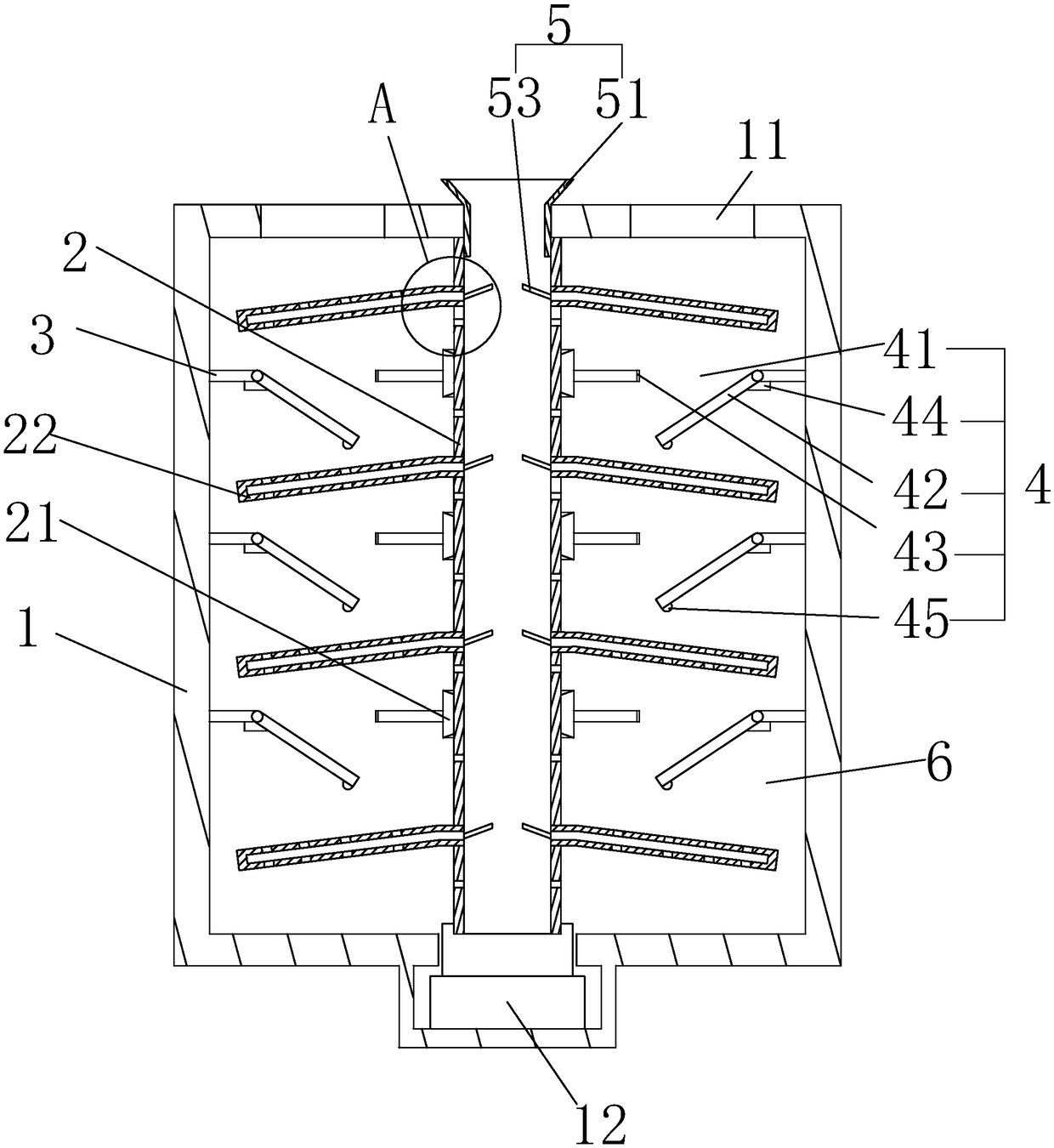

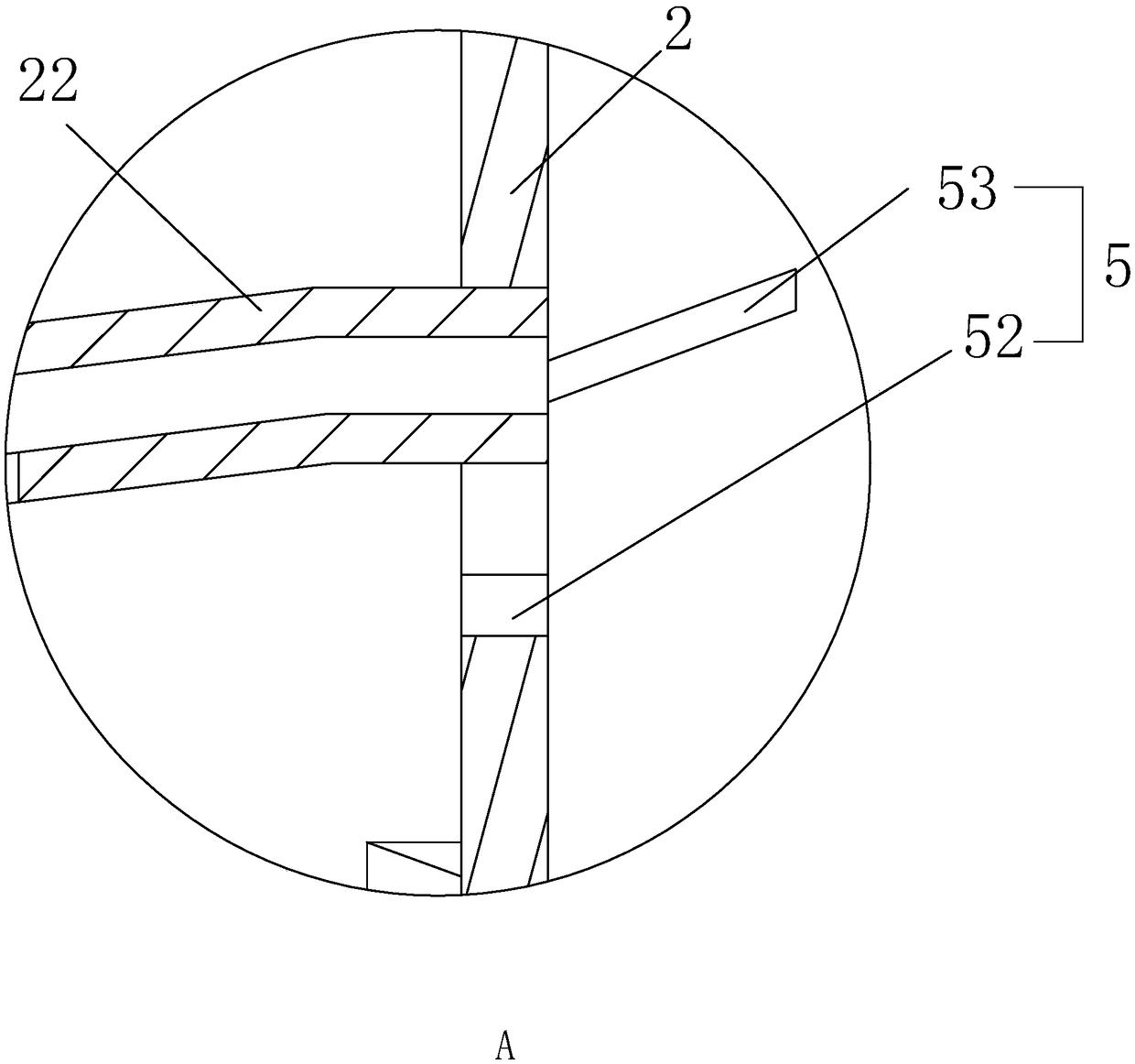

Intelligent disproportionated rosin potassium soap rubber additive blender and using method thereof

InactiveCN108786641ALow running costImprove mixing efficiencyRotary stirring mixersTransportation and packagingEngineeringRosin

The invention discloses an intelligent disproportionated rosin potassium soap rubber additive blender and a using method thereof. The intelligent disproportionated rosin potassium soap rubber additiveblender comprises a charging barrel; a stirring shaft, which is controlled to rotate by means of a driving mechanism, is arranged in the middle of the interior of the charging barrel; a plurality ofconnecting bearings are arranged in an array way on the outer circumference surface of the stirring shaft along the height direction; a plurality of spacer plates are arranged in an array way in the charging barrel along the height direction; the outer side edges of the spacer plates are separately connected and fixed with the inner wall of the charging barrel; the outer rings of the connecting bearings are fixedly connected in the spacer plates; the spacer plates are separately provided with a control mechanism for controlling the blanking amount of a rubber raw material; a plurality of stirring rods are fixedly arranged in a circular array way at the middle position between every two spacer plates on the stirring shaft; the stirring shaft is provided with a disproportionated rosin potassium soap rubber additive blanking mechanism. The intelligent disproportionated rosin potassium soap rubber additive mixer can shorten the blender running time and improve the working efficiency whileenabling a great deal of the rubber raw material-disproportionated rosin potassium soap rubber additive to be fully mixed.

Owner:NANJING WUSONG FORESTRY CHEM

A kind of disinfectant and preparation method thereof

InactiveCN102293199AEfficient killingPrevention and Control of TransmissionSoap detergents with organic compounding agentsBiocideDisinfectantPotassium hydroxide

The invention relates to a disinfectant and a preparation method thereof. The formula of the disinfectant is: p-chloro-m-xylenol, coconut oleic acid, potassium hydroxide, isopropanol, pine oil and deionized water, and its weight percentage is, 5.0 -7.0: 6.5-9.5: 3.7-5.4: 15.0-25.0: 3.0-6.0: margin. The preparation includes: (1) adding deionized water and potassium hydroxide, stirring, heating up to 90°C-100°C, and then adding coconut oleic acid to make potassium coconut oleate soap; (2) mixing p-chloro-m-xylenol with Mix isopropanol, heat up to dissolve, then add deionized water and the above-mentioned potassium coconut oleate soap, stir; cool to 30°C-35°C, add pine oil, stir, add deionized water and continue stirring, and the product is ready. The disinfectant solution of the invention can effectively kill 99.999% of intestinal pathogenic bacteria, pyogenic cocci and pathogenic yeasts; the preparation method is simple, the cost is low, and it is suitable for industrial production.

Owner:SHANGHAI SOAP GRP RUGAO

Butyl latex and preparation method thereof as well as preparation method of gloves prepared from butyl latex

InactiveCN109503963ASolve problems such as low conversion rateImprove conversion rateGlovesCoatingsPolymer sciencePolyvinyl alcohol

The invention discloses butyl latex. The butyl latex is prepared from the following raw materials in parts by weight: 100 parts of butyl rubber paste, 11-19 parts of an emulsifier mixture, 13-18 partsof a mixed dispersing system and 0-0.5 part of a stabilizer KOH (potassium hydroxide); the emulsifier mixture is prepared from the following raw materials in parts by weight: 4-6 parts of oleic acid,2-4 parts of the stabilizer KOH, 1-3 parts of potassium dihydrogen phosphate, 2-4 parts of polyvinyl alcohol and 2-4 parts of potassium soap, the potassium soap is prepared from the following raw materials by mass percent: 75-85% of castor oil, 10% of the stabilizer KOH and the balance of an aqueous solution. Solid butyl rubber is prepared into the butyl latex, the emulsifier and the like are added in a preparation process, gel particles or gum residue generated by mechanical action in the preparation process of latex are reduced, the problem that the conversion rate of the butyl latex is lowis solved, the conversion rate of the butyl latex can be increased by 12% or above compared with that of existing butyl latex, the process stability is good in the production process of the gloves, and the prepared gloves have excellent tensile strength.

Owner:GUANGZHOU DOUBLE ONE LATEX PROD CO LTD

Preparation method of disproportionated rosin potassium soap

InactiveCN103058857AReduce consumptionLight colorCarboxylic acid salt preparationPotassium soapRosin

The invention relates to a preparation method of disproportionated rosin potassium soap, and provides a safe, environment-friendly, low-consumption, time-saving, low-production-cost disproportionated rosin potassium soap preparation method utilizing low temperature and normal pressure. The method comprises the steps of: potassium hydroxide dissolving, precipitating, preheating, saponification reaction, cooling, impurity removing, and canning.

Owner:ERCHUANG FUJIAN CHEM TECH

Sterilization type clothes washing agent

InactiveCN102041185ASimple recipeCationic surface-active compoundsDetergent compounding agentsCoconut oilPotassium

The invention relates to a sterilization type clothes washing agent which is characterized by being prepared from the raw materials in percent by weight: 30-40 percent of sodium dodecyl benzene sulfonate, 10-20 percent of caustic soda flake, 5-15 percent of coconut oil fatty acid diethanolamide, 20-30 percent of terpinol, 2-3 percent of potassium soap, 1-2 percent of isopropanol and 4-6 percent of water. The sterilization type clothes washing agent can be made according to a making method of the conventional washing agent. The invention has reasonable formula, better cleaning effect and better sterilization and disinfection effect, and is beneficial to the maintaining of the health of people.

Owner:程聪

Potassium soaps that can be thickened with chloride salts

ActiveUS20160376526A1Improve clarityHigh viscosityCosmetic preparationsFatty acids production/refiningPotassium hydroxideOleic Acid Triglyceride

Natural liquid potassium soap compositions and methods of manufacturing and using the same are provided with thickening by the addition of chloride salts, such as sodium chloride and potassium chloride. The natural liquid potassium soap compositions may contain one or more fatty acids with carbon length ranging from four (C4) to twenty-two (C22) or natural fatty acid mixtures with coconut oil, olive oil, tallow, sunflower oil, safflower oil, and / or tall oil fatty acids which are saponified with lye. The saponification lye is preferably potassium hydroxide. Preferred embodiments contain potassium salts of fatty acids comprising at least oleic acid (C18:1 cis-9), olive oils, coconut oils or mixtures thereof. The chloride salt is added in either solid or liquid form following saponification and neutralization.

Owner:VANGUARD SOAP LLC

Cleaning agent

ActiveCN101144052AEasy to operateLow costAlkali/ammonium soap compositionsIndustrial equipmentCleansing Agents

The present invention relates to cleaning agent for removing oil materials and organic materials. The components include that disproportionated rosin potassium soap is 2 to 5 percent, sodium carbonate is 1 to 2 percent, organic silica antifoam agent is 0.002 to 0.007 percent, and others are water. The cleaning agent provided by the present invention has the advantages that the source of the raw material is convenient, the operation is simple, the cost is low, etc., and the cleaning agent is especially suitable for cleaning the organic materials and the oil stain of the inner wall of the industrial equipment, the pipeline of the drainage system or the pipe wall of the culvert.

Owner:PETROCHINA CO LTD

Cement concrete water reducing agent suitable for machine-made sand

Belonging to the technical field of environmental protection building materials, the invention in particular relates to a cement concrete water reducing agent suitable for machine-made sand. According to a technical scheme, the cement concrete water reducing agent suitable for machine-made sand is composed of the following components by weight: 8-60 parts of carboxylated styrene butadiene rubber powder, 5-20 parts of potassium aliphatate soap, 10-30 parts of starch, and 10-40 parts of a sodium hydroxide solution. The water reducing agent provided by the invention has very good volume compatibility with machine-made sand, can effectively ensure dispersion of the water reducing agent in concrete, has high water reducing rate and good fluidity, and can obviously improve the fluidity and workability of cement concrete for machine-made sand.

Owner:UNIV OF JINAN

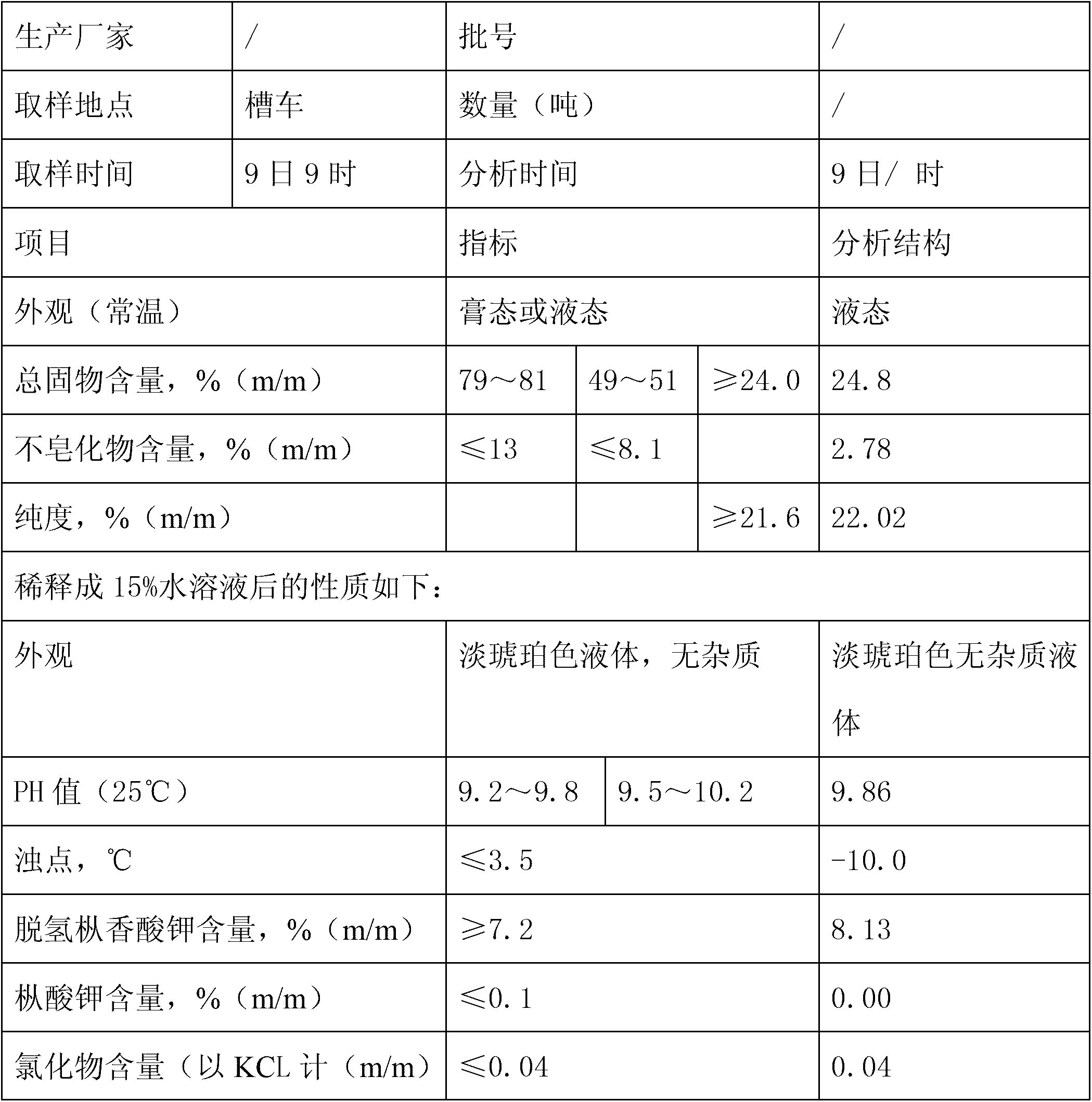

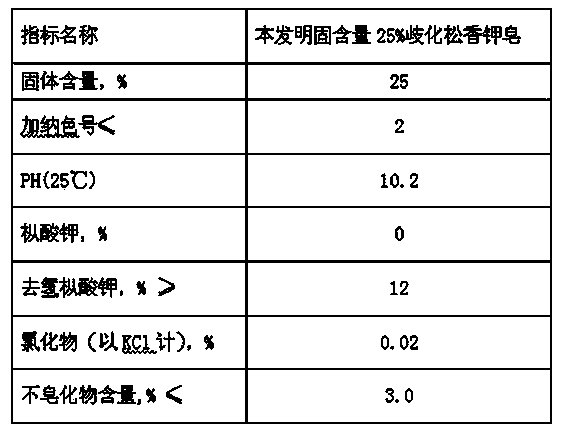

Preparation method of disproportionated rosin potassium soap with solid content of 25 percent

InactiveCN103451051AImprove conversion rateReduce the presence of impuritiesResin soap manufacturingReaction temperaturePotassium hydroxide

The invention discloses a preparation method of disproportionated rosin potassium soap with the solid content of 25 percent, and relates to the technical field of deep processing of rosin. The preparation method comprises the following steps: performing vacuum distillation on gum rosin to obtain refined gum rosin; adding a palladium / carbon catalyst to perform a disproportionation reaction for 2.5-3.5 hours at the reaction temperature of 270-280 DEG C; filtering to remove the palladium / carbon catalyst after the reaction is finished to obtain solid disproportionated rosin; putting the obtained solid disproportionated rosin and a 45-50% potassium hydroxide solution in a reactor to perform a saponification reaction so as to obtain the disproportionated rosin potassium soap with the solid content of 25 percent, wherein the reaction time is 0.5-1 hour and the reaction temperature is 62-68 percent. Compared with the prior art, the preparation method has the advantages of low production cost and more stable, safer and more efficient preparation process; the disproportionated rosin potassium soap as a finished product is lighter in color and better in quality.

Owner:WUZHOU PINE CHEM

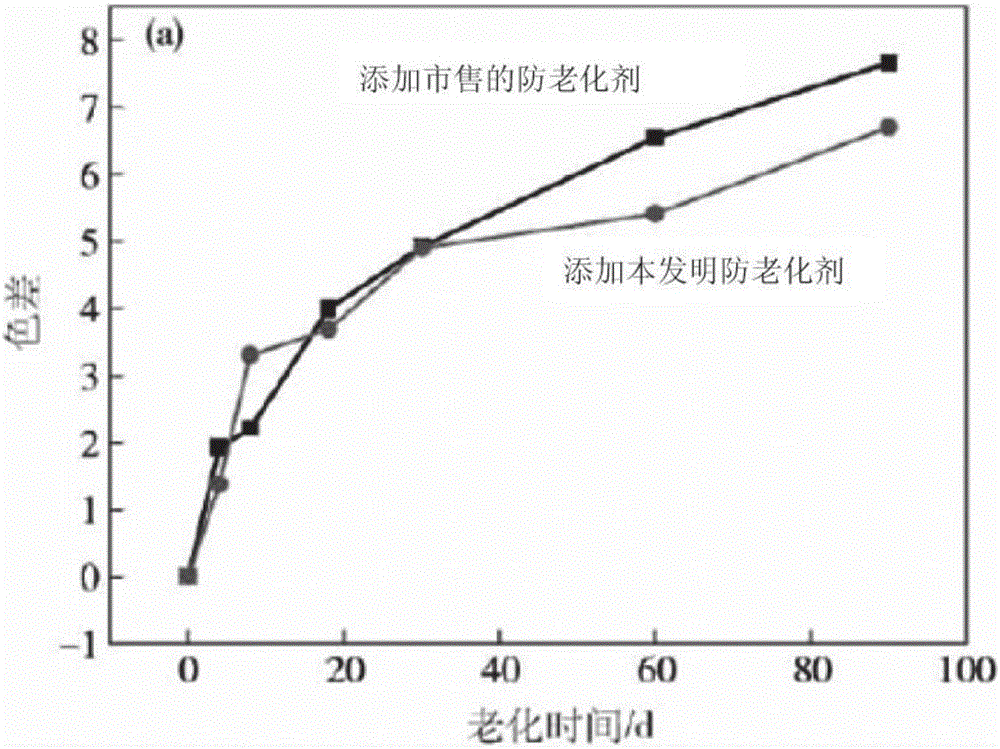

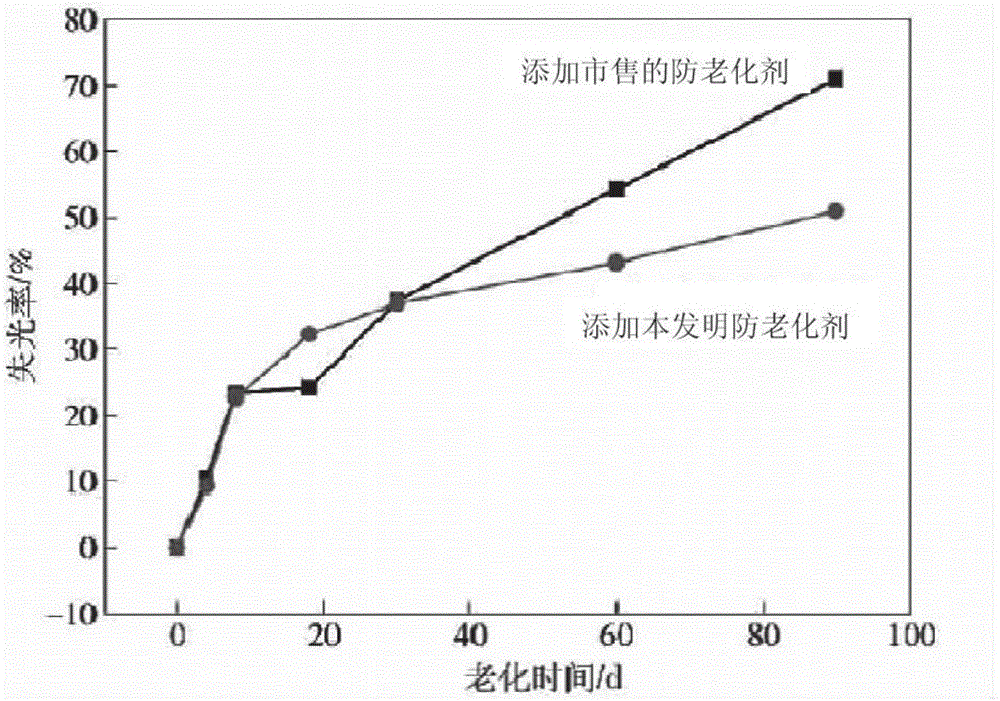

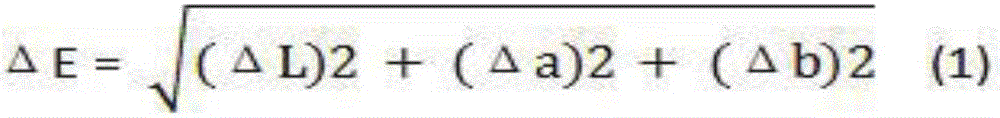

Rubber anti-aging agent composition and application thereof

The invention relates to a rubber anti-aging agent composition and belongs to the field of rubber preparation.The rubber anti-aging agent composition aims at overcoming the technical defects that a great number of existing rubber anti-aging agents are toxic and poor in storage stability.The rubber anti-aging agent composition is prepared from active components, including 10-12 parts of zinc stearyl lactylate, 6-15 parts of poly butyl bisphenol, 40-50 parts of tri (nonylphenyl) phosphite ester, 3-8 parts of disproportionated rosin potassium soap, 2-7 parts of N-isopropyl-N'-phenylenediamine, 5-10 parts of vinylation phenol, 5-10 parts of xylene formaldehyde resin, 8-12 parts of 5-(3, 5-bi-tert-butyl-4-hydroxy-benzyl)-1, 3-dimethyl pyrimidine-2, 4, 6 (1H, 3H, 5H)-triketone and 5-8 parts of an anti-aging agent.The rubber anti-aging agent composition is excellent in aging resistance and quite suitable for being applied and popularized in the rubber industry.

Owner:GUANGZHOU HUANGLONG BIOTECH CO LTD

Liquid perfumed soap

InactiveCN102746959AStrong decontaminationEmollientSurface-active non-soap compounds and soap mixture detergentsLiquid soapsPotassiumFatty alcohol

The invention discloses a liquid perfumed soap. The liquid perfumed soap is prepared from 18-30% of a potassium soap, 3-5% of sodium dodecyl sulfate, 6-10% of fatty alcohol polyoxyethylene ether, 6-14% of fatty alcohol polyoxyethylene ether sodium sulfate, 12-16% of coconut oil fatty acid monoethanol amide, 0.4-1.8% of disodium ethylenediamine tetraacetate, 1-3% of acetylated lanolin, 0.2-1.0% of citric acid, 0.5-2% of glycol monostearate, 0.5-2.5% of sodium chloride, 0.001-0.003% of a pigment, 0.02-0.04% of an essence, 0.02-0.05% of methylparaben, and the balance water. The liquid perfumed soap provided in the invention has the effects of good decontamination property, skin moistening, hard water resistance and the like.

Owner:NANTONG HONGLIDA KNITTING

Shower gel containing rice vinegar

ActiveCN100444826CReduce starch contentReduce sedimentCosmetic preparationsToilet preparationsCarboxymethyl cellulosePreservative

The invention provides a shower cream containing rice vinegar, wherein the raw materials include (by weight percent) potash soap 20-40%, lycine 2-4%, carboxymethyl cellulose 0.5-1.5%, rice vinegar 0.5-1.5%, perfume compound 0.5-1.5%, distilled water 48-68%, preservative agent 0.5-1% and penetrating agent 0.2-1%.

Owner:重庆灵方生物技术有限公司

Nanometer graphite lubricant for copper and aluminum wiredrawing and preparation method thereof

InactiveCN103351921AAvoid unwanted distractionsImprove the lubrication effectLubricant compositionPolyesterEpoxy

The invention provides a nanometer graphite lubricant for copper and aluminum wiredrawing and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 2-3 parts of castor oil potassium soap, 12-13 parts of chlorinated paraffin, 1-2 parts of boric acid, 1-2 parts of ricinoleic acid polyester, 1-2 parts of cyanuric acid zinc, 2-3 parts of methyl triethoxysilane, 1-2 parts of an anti-scorching agent CTP, 2-3 parts of epoxy linseed oil, 0.1-0.2 parts of nanometer graphite, 2-3 parts of a film forming auxiliary agent and 12-130 parts of water. According to the invention, the nanometer graphite is used as a lubricating component, thereby improving a lubricating effect and obviously increasing a wiredrawing speed. The anti-scorching agent is added in the formula, so as to prevent adverse interferences of heat on lubricant performances during the wiredrawing, thereby prolonging a using period.

Owner:安徽富华电子集团有限公司

Anhydrous laundry detergent and preparation method thereof

ActiveCN104818167AExtended shelf lifeConvenient and quick laundry modeSurface-active non-soap compounds and soap mixture detergentsActive agentPreservative

The invention discloses anhydrous laundry detergent and a preparation method thereof. The anhydrous laundry detergent comprises 8 to 12% of ethoxylated lauryl alcohol sulfate, 16 to 24% of non-ionic surfactant, 2 to 6% of potassium aliphatate soap, 0.1 to 0.5% of enzyme, 0.1 to 0.3% of sodium citrate, 0.1 to 0.5% of essence, 0.02 to 0.12% of preservative, 0.03 to 0.14% of pigment and 57 to 73% of solvent. The anhydrous laundry detergent is mild and free of stimulation, the consumption is less, the efficiency is high and the cleaning capability is high, the production cost is low, and the popularization and the application can be achieved.

Owner:WALCH GUANGZHOU COMMODITY

Preparation method of light-colour disproportionated rosin potassium soap with solid content of 80%

InactiveCN103435473AGood lookingImprove the level ofCarboxylic compound separation/purificationRosinSolid content

The invention discloses a preparation method for light-colour disproportionated rosin potassium soap with a solid content of 80%, which relates to the technical field of rosin deep processing. The preparation method comprises the following steps of adding the disproportionated rosin potassium soap with the solid content of 80% in a reaction container and heating, when the temperature rises to 70-90 DEG C, dripping a decolourant for a decolouration reaction, wherein the decolourant is peroxide K, and the mass percentage of the decolourant to the disproportionated rosin potassium soap with the solid content of 80% is (0.002 to 0.005): 1; stirring for 20-40 minutes; and after stirring, cooling, discharging when the temperature is reduced to be lower than 40 DEG C, so as to obtain the light-colour disproportionated rosin potassium soap with the solid content of 80%. The 1-3 Garner colour numbers of the light-colour disproportionated rosin potassium soap with the solid content of 80% are reduced compared with the Garner colour number of the disproportionated rosin potassium soap with the solid content of 80% and without any colour processing, so that the light-colour disproportionated rosin potassium soap with the solid content of 80% is improved in appearance, the level of the product is increased, and the needs of the market are met.

Owner:WUZHOU PINE CHEM

Plasticine

The invention belongs to the field of teaching and living, and particularly relates to plasticine. The plasticine comprises the following components in weight percent: liquid petrolatum, paint, isopropyl alcohol, spice, potash soap, and the balance of clay. The plasticine can effectively reduce manufacturing cost, and is simple and convenient to manufacture.

Owner:YANTAI DAYANG PHARMA GRP

Compound antioxidant for ABS latex

The invention discloses a compound antioxidant for ABS latex, comprising the following components of A-L polyphenol and dilauryl thiodipropionate; according to weight ratio of 1:0.8 to 1:2, the dilauryl thiodipropionate and the A-L polyphenol are mixed and melted, deionized water and rosin potassium soap with the weight percentage concentration of 80 to 90 percent are added, the obtained mixture is homogenized and emulsified at high speed, and then is filtered so as to obtain nano-grade milky A-L / DLTDP compound emulsified liquid with solid particle size of less than 1 micrometer; the solid weight content of the A-L / DLTDP compound emulsified liquid is 40 to 60 percent, the ratio of the added weight of the deionized water and the weight of the A-L polyphenol is 1.5 to 2:1, and the ratio of the added weight of the rosin potassium soap and the weight of the A-L polyphenol is 0.2 to 0.3:1. The compound antioxidant has better oxidation resistance and anti-aging performance, is economical andeffective and is used for ABS latex.

Owner:陶雷

Preparation method of disproportionated rosin potassium soap with light-color solid content of 25 percent

The invention discloses a preparation method of disproportionated rosin potassium soap with the light-color solid content of 25 percent and relates to the technical field of resin deep processing. The preparation method comprises the steps of adding the disproportionated rosin potassium soap with the solid content of 25 percent into a reaction container for heating, increasing the temperature to 60 to 80 DEG C, dropping hydrogen peroxide for a decolorizing reaction, wherein the mass ratio of the hydrogen peroxide to the disproportionated rosin potassium soap with the solid content of 25 percent is (0.003-0.005):1, and then performing agitation for 5 to 10min; after stopping the agitation, reducing the temperature and discharging when the temperature is lower than 40 DEG C to obtain the disproportionated rosin potassium soap with the light-color solid content of 25 percent. The Gardner color number of the disproportionated rosin potassium soap with the light-color solid content of 25 percent disclosed by the invention is 1 to 3 color numbers lower than the Gardner color number of disproportionated rosin potassium soap with the solid content of 25 percent not subjected to any color treatment, thereby the appearance of the disproportionated rosin potassium soap with the light-color solid content of 25 percent disclosed by the invention is improved, and the grade of a product is improved and the market demands are satisfied.

Owner:广西梧州通轩林产化学有限公司

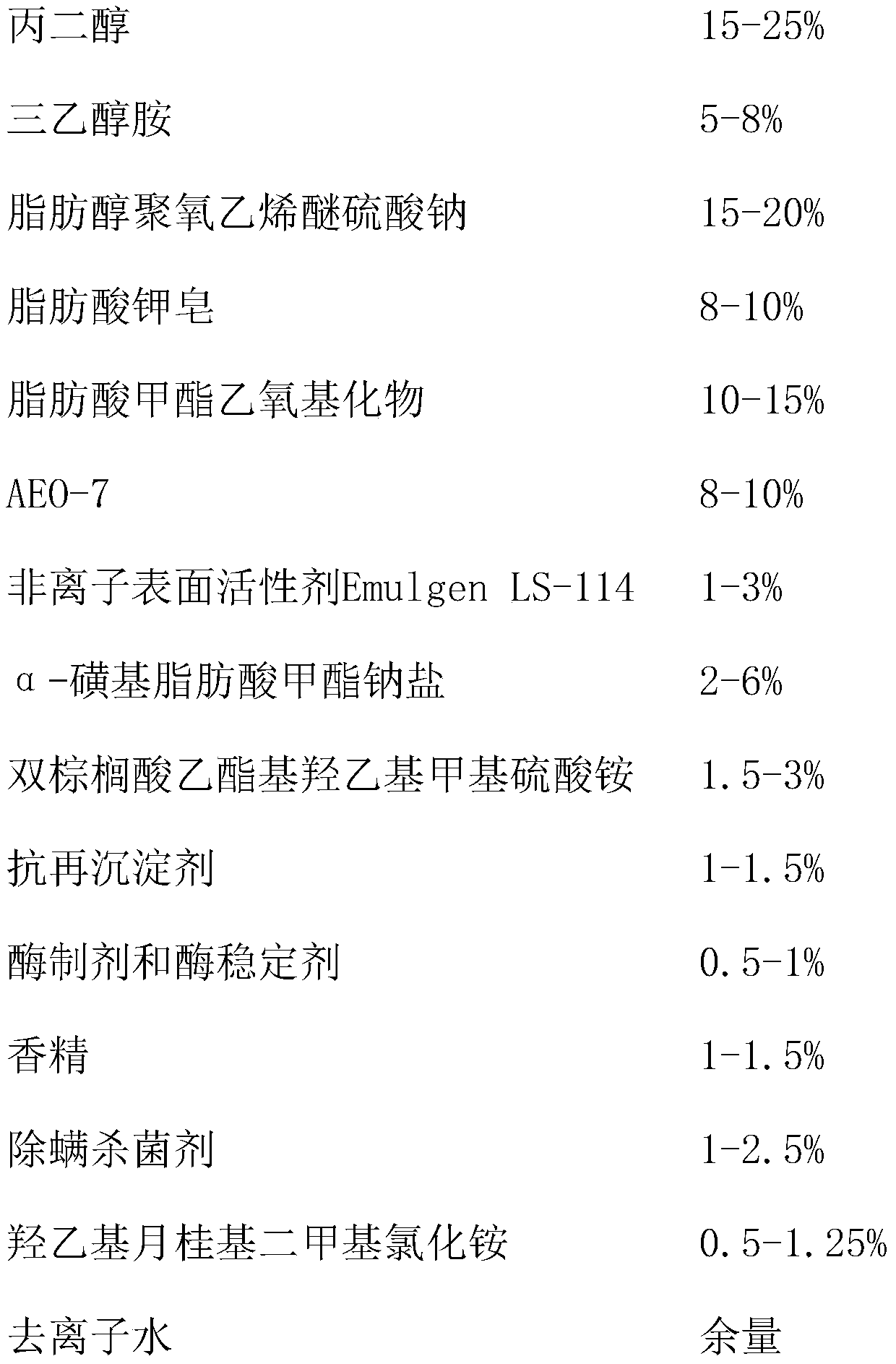

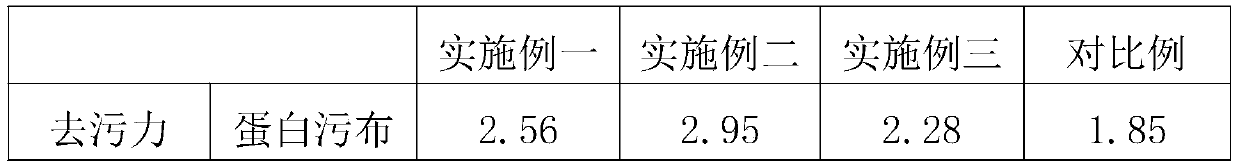

Underwear type laundry condensate beads and preparation method thereof

InactiveCN111471543ANo pollution in the processGood decontamination effectCationic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsEthyl palmitateFatty alcohol

The invention relates to the field of daily chemical detergents. The invention provides underwear type laundry condensate beads and a preparation method thereof. The underwear type laundry condensatebeads comprise the following components in percentage by mass: 15 to 25% of propylene glycol, 15 to 20% of fatty alcohol-polyoxyethylene ether sodium sulfate; 8 to 10% of fatty acid potassium soap; 10to 15% of fatty acid methyl ester ethoxylate; 8 to 10% AEO-7, 1-3% of nonionic surfactant Emulgen LS-114, 2 to 6% of alpha-sulfo fatty acid methyl ester sodium salt, 1.5%-3% of dipalmitic acid ethylester hydroxyethyl methyl ammonium sulfate, 1%-1.5% of an anti-reprecipitation agent, 0.5%-1% of an enzyme preparation and enzyme stabilizer, 1%-1.5% of an essence, 1%-2.5% of an acarus killing bactericide, 0.5%-1.25% of hydroxyethyl lauryl dimethyl ammonium chloride and the balance deionized water. The problems that existing laundry condensate beads only have efficient decontamination capacity and cannot give consideration to bacteriostasis and acarus killing are solved.

Owner:FUJIAN HENGAN HLDG CO LTD +1

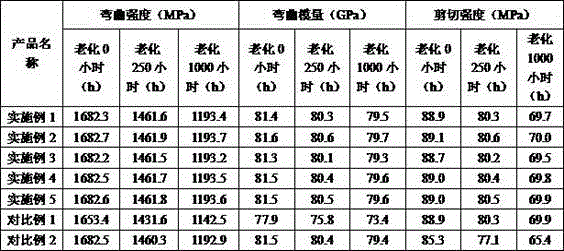

Anti-aging cable material and preparation method thereof

InactiveCN105733190AGood effectEffect: the aging-resistant cable material of the present invention has good mechanical properties before agingPlastic/resin/waxes insulatorsInsulated cablesBenzoic acidPolymer science

The invention provides an anti-aging cable material and a preparation method thereof. The preparation method comprises the following steps: mixing bisphenol F-type epoxy resin, hydantoin epoxy resin, polydimethyl siloxane, resveratrol, potassium aliphatate soap, trimellitic anhydride, methyl tetrahydrophthalic anhydride, ethylidene bis-stearamide, triethanolamine, dibutyltindilaurate, o-benzoic sulfimide, o-palmitoyl-L-ascorbic acid, ethyl p-hydroxybenzoate and butylated hydroxyanisole to obtain a mixture, stirring with a magnetic stirring machine under the rotating speed of 60 to 80 r / min for 30 to 50 min, pouring the mixture into a resin soaking tank, and adding carbon fibers and glass fibers to completely soak the mixture; putting the fibers into a die, curing in a drying oven under the temperature of 170 to 190 DEG C for 2 to 3 hours for forming, and finally performing drawing extrusion on a cured material. Before being aged, the anti-aging cable material is higher in mechanical performance, but even if the anti-aging cable material is aged for 1,000 hours, the mechanical performance is not changed greatly; therefore, the anti-aging cable material is excellent in aging resistance effect.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Low-foam easily-bleached degerming laundry detergent and preparation method thereof

InactiveCN111534388AControllable odorAdjust textureSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsDioxyethylene EtherFatty alcohol

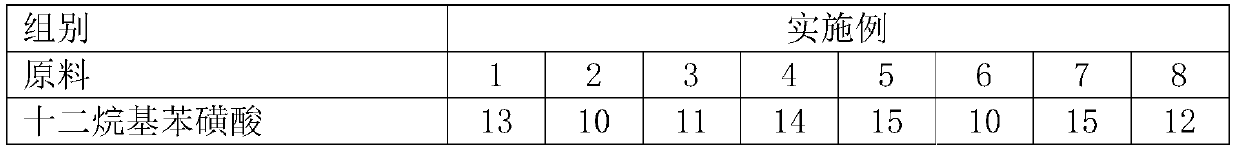

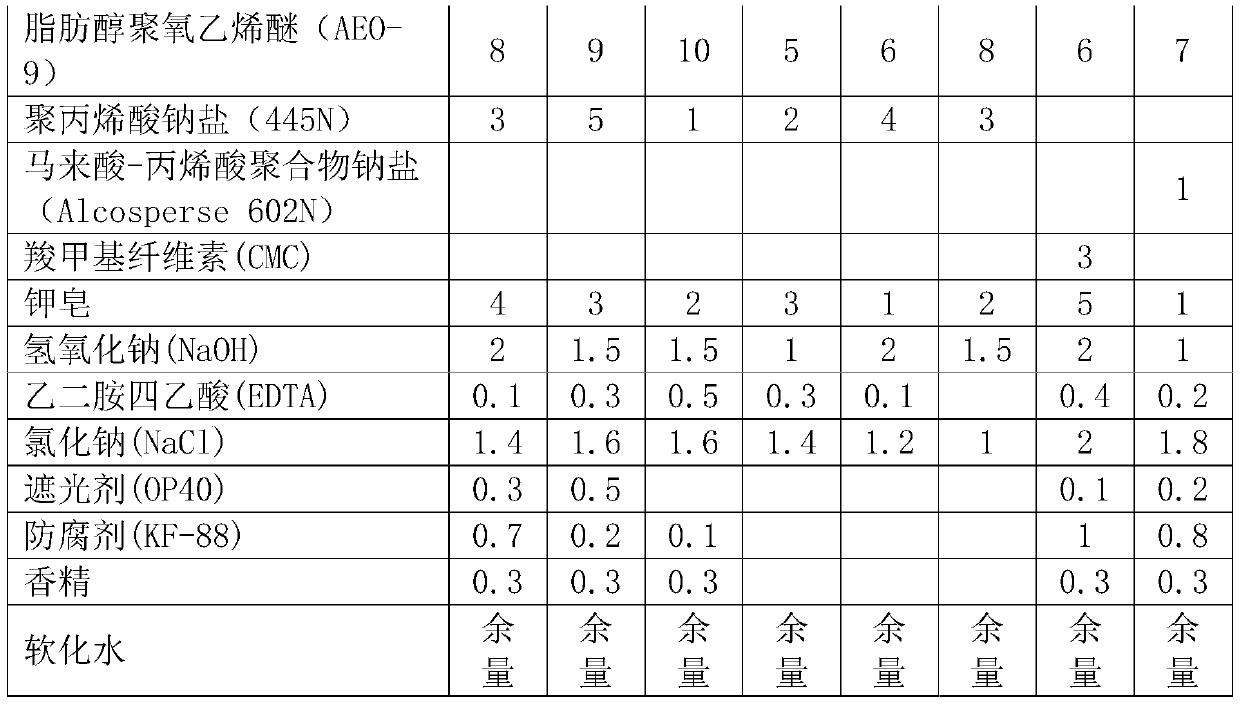

The invention discloses a low-foam easily-bleached degerming laundry detergent and a preparation method thereof, and belongs to the technical field of mixtures of non-ionic compounds and anionic compounds. The low-foam easy-to-bleach degerming laundry detergent is prepared from the following raw materials in percentage by mass: 10-15% of dodecylbenzene sulfonic acid, 5%-10% of fatty alcohol-polyoxyethylene ether, 1%-5% of a water-based high-molecular polymer, 1%-5% of potassium soap, 1%-2% of sodium hydroxide, 0%-0.5% of a chelating agent, 1%-2% of sodium chloride, 0%-0.5% of a preservative, 0.3% of essence and the balance of water. The preparation method comprises the following steps: preparing the dodecylbenzene sulfonic acid, the fatty alcohol-polyoxyethylene ether, the water-based high-molecular polymer, the potassium soap, the sodium hydroxide, the chelating agent, the sodium chloride, the preservative, the essence and the water in proportion, adding water into a batching kettle,adding sodium hydroxide, then adding dodecylbenzene sulfonic acid to enable the pH value to be 8.5-9.5, adding fatty alcohol-polyoxyethylene ether, sodium polyacrylate and potassium soap, adjusting the pH value to 8.0-10.0 and carrying out cooling and standing. The laundry detergent disclosed by the invention has the effects of low foam, easiness in bleaching and sterilization.

Owner:北京金鱼科技有限责任公司

Citronella, ginger and tea bran mixed bath cream

InactiveCN103054781AEmollientWith sterilizationCosmetic preparationsToilet preparationsPotassium soapChemistry

The invention relates to citronella, ginger and tea bran mixed bath cream which is characterized by comprising the following components according to parts by weight: 20-25 parts of the citronella liquid, 15-25 parts of the tea bran liquid, 15-23 parts of the ginger liquid, 22-35 parts of the amino potash soap and 5-15 parts of the potassium glycinate. The citronella, ginger and tea bran mixed bath cream provided by the invention has obvious effects of moistening skin, sterilizing, relieving itching, dispelling wind, dispelling cold, removing acarus and the like.

Owner:李海祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com