Anhydrous laundry detergent and preparation method thereof

An anhydrous laundry detergent and non-ionic surface technology, applied to chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problems of energy consumption, high production cost, and time-consuming production, and achieve extended The effect of shelf life, reduction of production cost, and system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

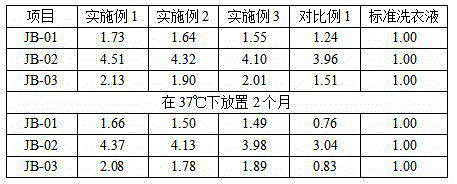

Examples

Embodiment 1

[0024] Embodiment 1, anhydrous laundry detergent of the present invention and its preparation

[0025] Formula: fatty alcohol polyoxyethylene ether sodium sulfate 100g, nonionic surfactant 200g (the weight ratio of fatty acid methyl ester ethoxylate and fatty alcohol polyoxyethylene (9) ether is 3:1), fatty acid potassium soap 30g, Enzyme 2g (the weight ratio of protease and amylase is 2:1), sodium citrate 1g, essence 1g, preservative 0.8g, pigment 0.7g, solvent 664.5g (the weight ratio of ethanol and glycerin is 1 : 23).

[0026] Preparation: Add non-ionic surfactant to the solvent, stir evenly, then add fatty acid potassium soap, sodium fatty alcohol polyoxyethylene ether sulfate, stir evenly, finally add sodium citrate, enzyme, preservative, essence, pigment, stir evenly and serve Can.

Embodiment 2

[0027] Embodiment 2, anhydrous laundry detergent of the present invention and preparation thereof

[0028] Formula: fatty alcohol polyoxyethylene ether sodium sulfate 80g, nonionic surfactant 240g (the weight ratio of fatty acid methyl ester ethoxylate and fatty alcohol polyoxyethylene (9) ether is 5:1), fatty acid potassium soap 20g, Enzyme 5g (the weight ratio of protease and amylase is 2:1), sodium citrate 1g, essence 1g, preservative 0.2g, pigment 1.4g, solvent 651.4g (the weight ratio of ethanol and glycerol is 1:20).

[0029] Preparation: Add non-ionic surfactant to the solvent, stir evenly, then add fatty acid potassium soap, sodium fatty alcohol polyoxyethylene ether sulfate, stir evenly, finally add sodium citrate, enzyme, preservative, essence, pigment, stir evenly and serve Can.

Embodiment 3

[0030] Embodiment 3, anhydrous laundry detergent of the present invention and its preparation

[0031] Formula: fatty alcohol polyoxyethylene ether sodium sulfate 120g, nonionic surfactant 160g (the weight ratio of fatty acid methyl ester ethoxylate and fatty alcohol polyoxyethylene (9) ether is 1:1), fatty acid potassium soap 60g, Enzyme 1g (the weight ratio of protease and amylase is 2:1), sodium citrate 3g, essence 5g, preservative 1.2g, pigment 0.3g, solvent 649.5g (the weight ratio of ethanol and glycerin is 1 : 25).

[0032] Preparation: Add non-ionic surfactant to the solvent, stir evenly, then add fatty acid potassium soap, sodium fatty alcohol polyoxyethylene ether sulfate, stir evenly, finally add sodium citrate, enzyme, preservative, essence, pigment, stir evenly and serve Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com