Anti-aging cable material and preparation method thereof

An anti-aging and cable technology, applied in the field of materials, can solve problems such as the decline of bearing capacity, accelerated aging of cables, threats to personal safety, etc., and achieve good effects, good aging resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An aging-resistant cable material, prepared from the following components in parts by weight: 15 parts of bisphenol F epoxy resin, 25 parts of hydantoin epoxy resin, 0.3 part of polydimethylsiloxane, and 0.11 part of resveratrol , 0.12 parts of fatty acid potassium soap, 1.5 parts of trimellitic anhydride, 1.1 parts of methyl tetrahydrophthalic anhydride, 0.15 parts of ethylene bis stearic acid amide, 4 parts of carbon fiber, 3 parts of glass fiber, 0.6 part of triethanolamine, 0.3 part of dibutyltin dilaurate 0.11 parts of o-benzoylsulfonimide, 0.15 parts of ascorbyl palmitate, 0.11 parts of ethyl p-hydroxybenzoate, and 0.11 parts of butyl hydroxyanisole.

[0017] The preparation method of the above aging-resistant cable material is as follows: first bisphenol F type epoxy resin, hydantoin epoxy resin, polydimethylsiloxane, resveratrol, fatty acid potassium soap, trimellitic anhydride, methyltetrahydrophthalic anhydride, Ethylene bis stearic acid amide, triethanolamine...

Embodiment 2

[0019] An aging-resistant cable material, prepared from the following components in parts by weight: 25 parts of bisphenol F epoxy resin, 35 parts of hydantoin epoxy resin, 0.4 part of polydimethylsiloxane, and 0.16 part of resveratrol , 0.17 parts of fatty acid potassium soap, 2.5 parts of trimellitic anhydride, 1.6 parts of methyl tetrahydrophthalic anhydride, 0.25 parts of ethylene bis stearic acid amide, 5 parts of carbon fiber, 4 parts of glass fiber, 0.9 part of triethanolamine, 0.4 part of dibutyltin dilaurate 0.16 parts of o-benzoylsulfonimide, 0.25 parts of ascorbyl palmitate, 0.16 parts of ethyl p-hydroxybenzoate, and 0.17 parts of butyl hydroxyanisole.

[0020] The preparation method of the above aging-resistant cable material is as follows: first bisphenol F type epoxy resin, hydantoin epoxy resin, polydimethylsiloxane, resveratrol, fatty acid potassium soap, trimellitic anhydride, methyltetrahydrophthalic anhydride, Ethylene bis stearic acid amide, triethanolamine...

Embodiment 3

[0022] An aging-resistant cable material, prepared from the following ingredients in parts by weight: 10 parts of bisphenol F epoxy resin, 20 parts of hydantoin epoxy resin, 0.2 part of polydimethylsiloxane, and 0.1 part of resveratrol , 0.1 part of fatty acid potassium soap, 1 part of trimellitic anhydride, 1 part of methyl tetrahydrophthalic anhydride, 0.1 part of ethylene bis stearic acid amide, 3 parts of carbon fiber, 2 parts of glass fiber, 0.5 part of triethanolamine, 0.2 part of dibutyltin dilaurate 0.1 part of o-benzoylsulfonimide, 0.1 part of ascorbyl palmitate, 0.1 part of ethyl p-hydroxybenzoate, and 0.1 part of butyl hydroxyanisole.

[0023] The preparation method of the above aging-resistant cable material is as follows: first bisphenol F type epoxy resin, hydantoin epoxy resin, polydimethylsiloxane, resveratrol, fatty acid potassium soap, trimellitic anhydride, methyltetrahydrophthalic anhydride, Ethylene bis stearic acid amide, triethanolamine, dibutyltin dilau...

PUM

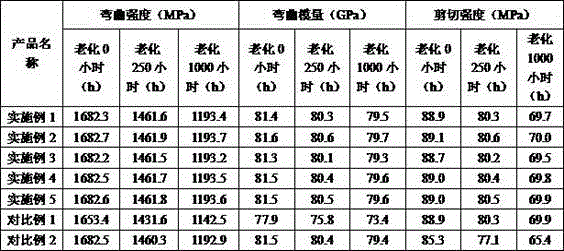

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com