Preparation method of disproportionated rosin potassium soap with solid content of 25 percent

A technology of disproportionated rosin potassium soap and disproportionated rosin, which is applied in chemical instruments and methods, resin soap manufacturing, detergent compositions, etc., can solve the problem of difficult control of the addition amount and addition rate of potassium hydroxide solution and disproportionated rosin liquid, Improve production costs, cleaning work difficulty and other issues, to achieve the effect of reducing impurities and by-products, improving success rate and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Gum rosin is vacuum-distilled to obtain refined gum rosin; then add palladium / carbon catalyst to carry out disproportionation reaction for 2.5 hours, the reaction temperature is 280°C, after the reaction finishes, filter and remove palladium / carbon catalyst to obtain solid disproportionated rosin; obtain solid disproportionated rosin and The potassium hydroxide solution of 48% is put into reactor and carries out the saponification reaction of 0.5 hour to obtain this solid content 25% disproportionated rosin potassium soap, and reaction temperature is 62 ℃;

[0022] The mass ratio of described solid disproportionated rosin to potassium hydroxide solution is: 2.8:1; 2 Protect.

Embodiment 2

[0024] Gum rosin is vacuum distilled to obtain refined gum rosin; then add palladium / carbon catalyst to carry out disproportionation reaction for 3 hours, the reaction temperature is 275 ° C, after the reaction finishes, filter and remove palladium / carbon catalyst to obtain solid disproportionated rosin; obtain solid disproportionated rosin and 45% potassium hydroxide solution is put into reactor and carries out the saponification reaction of 0.5 hour to obtain this solid content 25% disproportionated rosin potassium soap, and reaction temperature is 65 ℃;

[0025] The mass ratio of described solid disproportionated rosin to potassium hydroxide solution is: 3:1; 2 Protect.

Embodiment 3

[0027] Gum rosin is vacuum distilled to obtain refined gum rosin; then add palladium / carbon catalyzer and carry out disproportionation reaction for 3.5 hours, the reaction temperature is 270 ℃, filter and remove palladium / carbon catalyzer after reaction finishes, obtain solid disproportionated rosin; obtain solid disproportionated rosin and 50% potassium hydroxide solution is put into the reactor and carries out the saponification reaction of 1 hour to obtain this solid content 25% disproportionated rosin potassium soap, and the reaction temperature is 68 ℃;

[0028] The mass ratio of described solid disproportionated rosin to potassium hydroxide solution is: 3.0:1; 2 Protect.

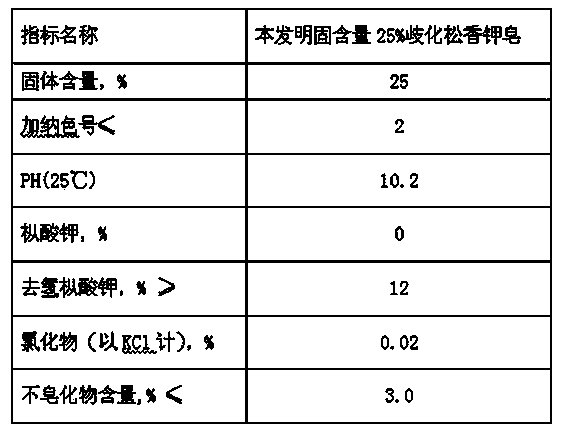

[0029] Solid content 25% disproportionated rosin potassium soap technical index of the present invention is as table 1.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com