Rubber anti-aging agent composition and application thereof

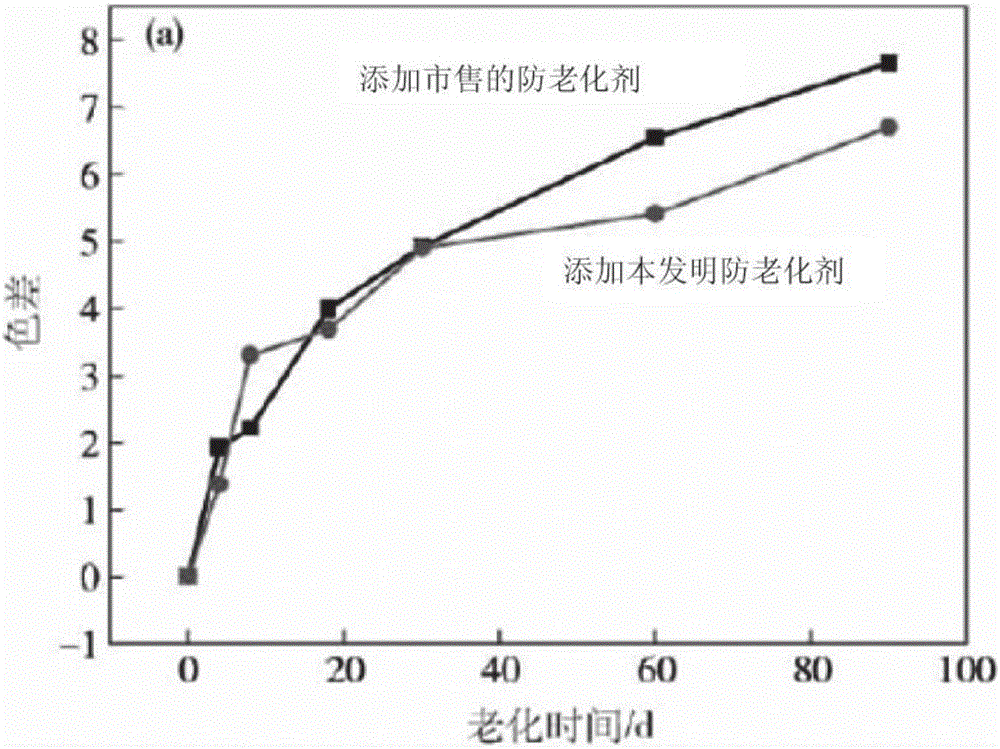

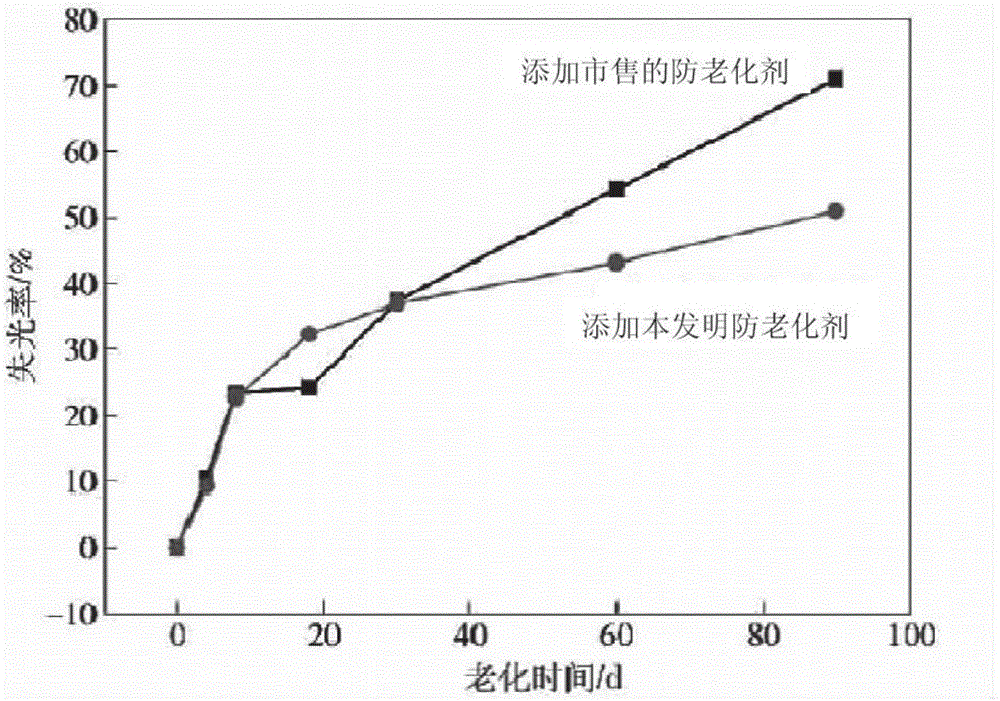

An anti-aging agent and composition technology, which is applied in the field of rubber preparation, can solve the problems of prone to blooming, lack of solubilizing genes, ideal anti-aging effect, etc., and achieve the effects of extremely low toxicity, stable storage, and excellent anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Rubber antiaging agent composition of the present invention

[0019] The rubber antiaging agent composition is prepared from the following active components: 10 parts of zinc stearoyl lactylate, 6 parts of polybutylbisphenol, 40 parts of tris(nonylphenyl) phosphite, disproportionated potassium abietate 3 parts of soap, 2 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 5 parts of vinylated phenol, 5 parts of xylene formaldehyde resin and 5-(3,5-di-tert-butyl-4 -8 parts of -hydroxy-benzyl)-1,3-dimethylpyrimidine-2,4,6(1H,3H,5H)-trione and 5 parts of antioxidant A.

Embodiment 2

[0020] Embodiment 2 Rubber antiaging agent composition of the present invention

[0021] The rubber antiaging agent composition is prepared from the following active components: 12 parts of zinc stearoyl lactylate, 15 parts of polybutyl bisphenol, 50 parts of tris(nonylphenyl) phosphite, disproportionated potassium abietate 8 parts of soap, 7 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 10 parts of vinylated phenol, 10 parts of xylene formaldehyde resin and 5-(3,5-di-tert-butyl-4 8-12 parts of -hydroxy-benzyl)-1,3-dimethylpyrimidine-2,4,6(1H,3H,5H)-trione and 8 parts of antioxidant A.

Embodiment 3

[0022] Embodiment 3 rubber antiaging agent composition of the present invention

[0023] The rubber antiaging agent composition is prepared from the following active components: 11 parts of zinc stearoyl lactylate, 10.5 parts of polybutylbisphenol, 45 parts of tris(nonylphenyl) phosphite, disproportionated potassium abietate 5.5 parts of soap, 4.5 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 7.5 parts of vinylated phenol, 7.5 parts of xylene formaldehyde resin and 5-(3,5-di-tert-butyl-4 10 parts of -hydroxy-benzyl)-1,3-dimethylpyrimidine-2,4,6(1H,3H,5H)-trione and 6.5 parts of antioxidant A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com