Low-foam easily-bleached degerming laundry detergent and preparation method thereof

A technology of laundry detergent and water-based polymer, applied in the direction of chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problems of low cost, difficult preparation of raw materials, high cost, etc., and achieve moderate viscosity and low odor Controllable, fluid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

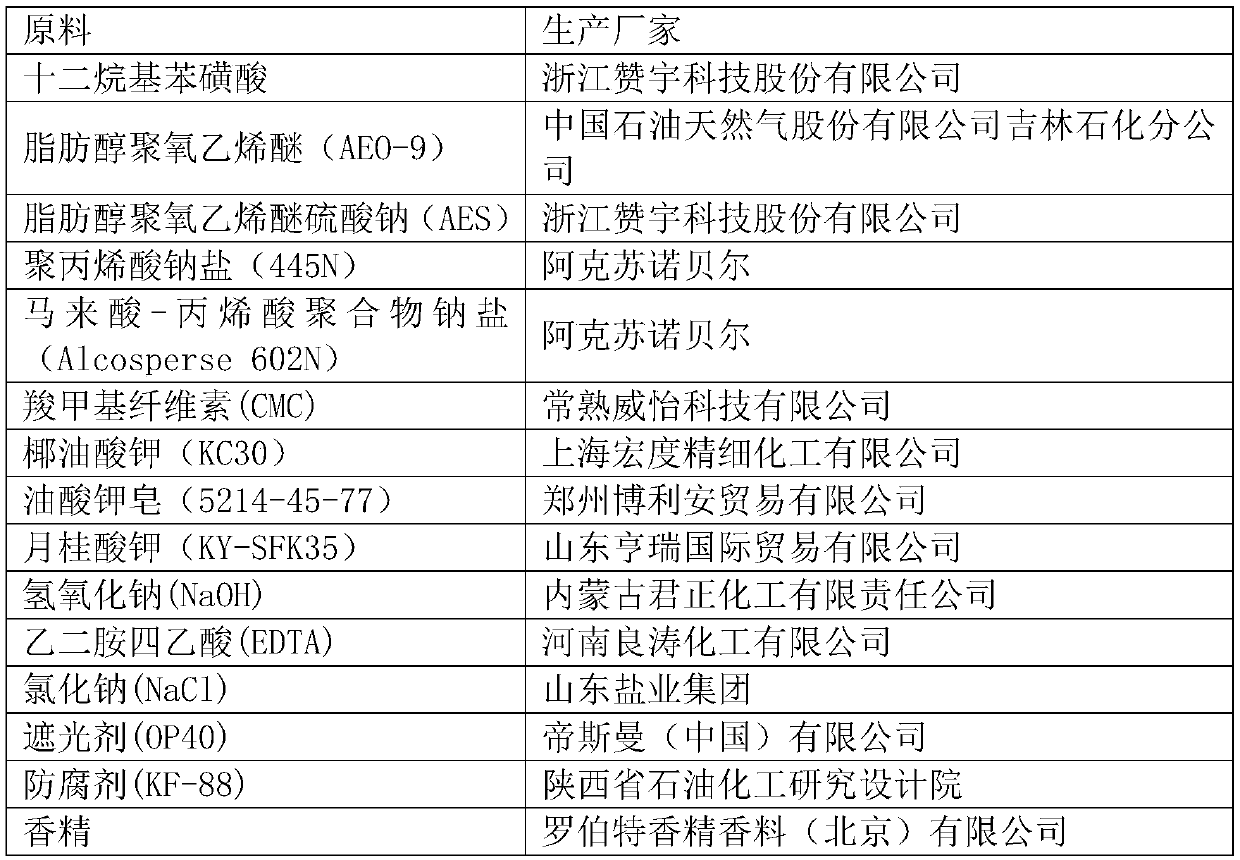

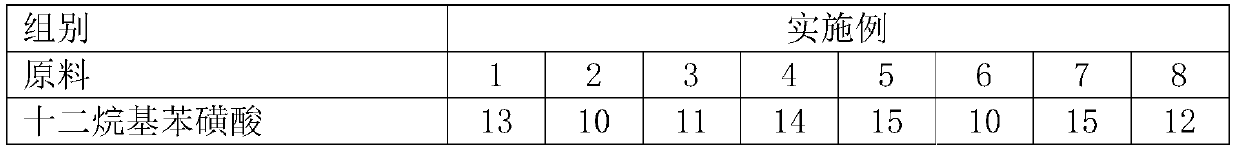

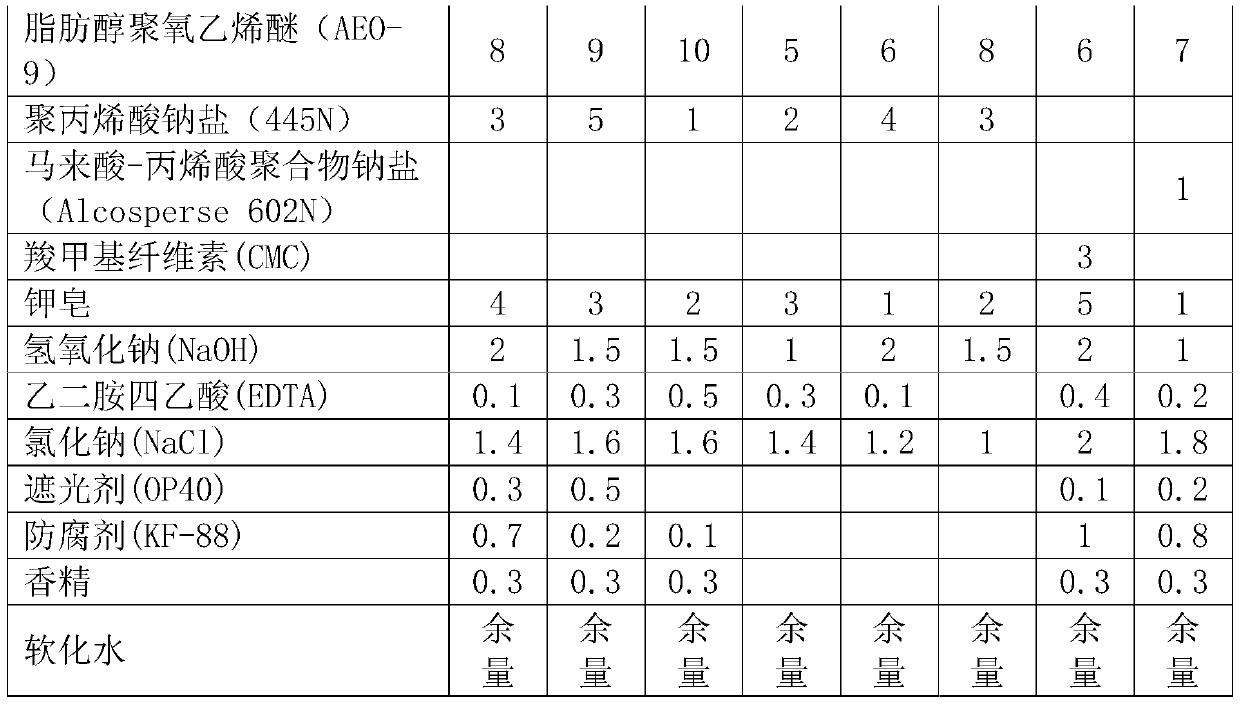

[0059] The mass percent of raw materials used in this embodiment is dodecylbenzenesulfonic acid 13, fatty alcohol polyoxyethylene ether 8, polyacrylic acid sodium salt 3, potassium cocoate (KC30) 4, sodium hydroxide 2, ethylenediaminetetra Acetic acid 0.1, sodium chloride 1.4, sunscreen 0.3, preservative 0.7 and essence 0.3.

[0060] The preparation method of low-foaming easy-to-bleach antibacterial laundry detergent is:

[0061] (1) Prepare dodecylbenzenesulfonic acid, fatty alcohol polyoxyethylene ether, polyacrylic acid sodium salt, potassium cocoate, sodium hydroxide, ethylenediaminetetraacetic acid, sodium chloride, sunscreen, and preservatives according to the ratio , essence and water; the water is deionized water.

[0062] (2) Add water to the batching kettle, add chelating agent and sodium hydroxide, start stirring, heat to 40°C, add dodecylbenzenesulfonic acid, make the pH value 9;

[0063] This step guarantees the pH value so that the laundry liquid prepared by th...

Embodiment 2

[0072] The kind of raw material of embodiment 2 is exactly the same as that of embodiment 1, and difference only is that raw material consumption is different. The raw material percentage of embodiment 2 is as shown in table 2 namely dodecylbenzenesulfonic acid 10, fatty alcohol polyoxyethylene ether 9, polyacrylic acid sodium salt 5, lauryl potassium soap 3, sodium hydroxide 1.5, ethylenediaminetetra Acetic acid 0.3, sodium chloride 1.6, sunscreen agent 0.5, preservative 0.2 and essence 0.3.

[0073] The preparation method of low-foaming easy-to-bleach antibacterial laundry detergent is:

[0074] (1) Prepare dodecylbenzenesulfonic acid, fatty alcohol polyoxyethylene ether, polyacrylic acid sodium salt, lauryl potassium soap, sodium hydroxide, ethylenediaminetetraacetic acid, sodium chloride, sunscreen, preservative according to the ratio , essence and water;

[0075] (2) Add water to the batching kettle, add chelating agent and sodium hydroxide, start stirring, heat to 30°C...

Embodiment 3

[0085]The difference between embodiment 3 and embodiment 2 is that the raw materials do not include a sunscreen agent, and the amount of each raw material is different. The raw material percentage of embodiment 3 is as shown in table 2 namely dodecylbenzenesulfonic acid 11, fatty alcohol polyoxyethylene ether 10, polyacrylic acid sodium salt 1, oleic acid potassium soap 2, sodium hydroxide 1.5, ethylenediaminetetra Acetic acid 0.5, sodium chloride 1.6, preservative 0.1 and essence 0.3.

[0086] The preparation method of the low-foaming and easy-to-bleach antibacterial laundry detergent is similar to the preparation method of Example 1, lacking a sunscreen, and the mass percentages of raw materials are different in addition:

[0087] (1) Prepare dodecylbenzenesulfonic acid, fatty alcohol polyoxyethylene ether, polyacrylic acid sodium salt, potassium oleate soap, sodium hydroxide, ethylenediaminetetraacetic acid, sodium chloride, preservatives, essence and water;

[0088] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com