Synthetic method of triazine net series herbicides

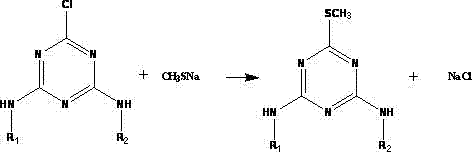

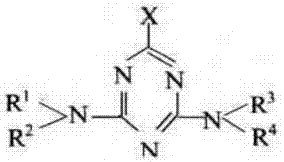

A technology of s-triazine and synthesis method, which is applied in the synthesis of s-triazine net series herbicides and the synthesis field of s-triazine herbicides. Deal with difficult problems and achieve considerable economic and social benefits, good product quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 1L reaction kettle, put 350mL of isopropanol, 245.88g of 20wt% sodium methyl mercaptide liquid and 160.00g of 97wt% atrazine respectively. After sealing, stir and mix and heat up to 115°C for 50min. The pressure was 0.34 MPa, and the temperature was lowered to 60° C. after the reaction. Stand still, divide the water, and the water layer is almost odorless after the solvent is recovered by distillation. The oil layer was transferred to a 500mL four-neck flask to distill and recover the solvent, and the residue was poured into a tray, cooled, crystallized and pulverized to obtain 163.02g of white powder. The content of arazine was 97.62% as determined by HPLC, and the yield based on atrazine was 97.31%.

Embodiment 2

[0034] In a 1L reaction kettle, put 350mL of isopropanol, 247.14g of 20wt% sodium methyl mercaptide liquid and 160.00g of 97% atrazine respectively. After sealing, stir and mix and heat up to 120°C for 45min. The pressure was 0.37MPa, and the temperature was lowered to 62°C after the reaction. Stand still, separate the water, and the water layer has no peculiar smell after the solvent is recovered by distillation. The oil layer was transferred to a 500mL four-neck flask to distill and recover the solvent, and the residue was poured into a tray, cooled, crystallized and pulverized to obtain 164.81g of white powder. The content of arazine was 96.88% as detected by HPLC, and the yield based on atrazine was 97.63%.

Embodiment 3

[0036] In a 1L reaction kettle, put 350mL of isopropanol, 249.66g of 20wt% sodium methyl mercaptide liquid and 160.00g of 97% atrazine respectively. After sealing, stir and mix and heat up to 118°C for 50min. The pressure is 0.35 MPa, and the temperature is lowered to 60° C. after the reaction. Stand still, divide the water, and the water layer is almost odorless after the solvent is recovered by distillation. The oil layer was transferred to a 500mL four-neck flask to distill and recover the solvent, and the residue was poured into a tray, cooled, crystallized and pulverized to obtain 165.48g of white powder. The content of arazine detected by HPLC was 96.97%, and the yield based on atrazine was 98.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com