Ionic liquid electrolyte for magnesium alloy surface treatment and method for electroplating aluminum on surface of magnesium alloy

An ionic liquid and surface treatment technology, which is applied in the field of ionic liquid electrolyte for magnesium alloy surface treatment and electroplating aluminum on the surface of magnesium alloy, can solve the problems of poor bonding force, affecting the quality of coating, high surface chemical activity, etc., and achieve good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

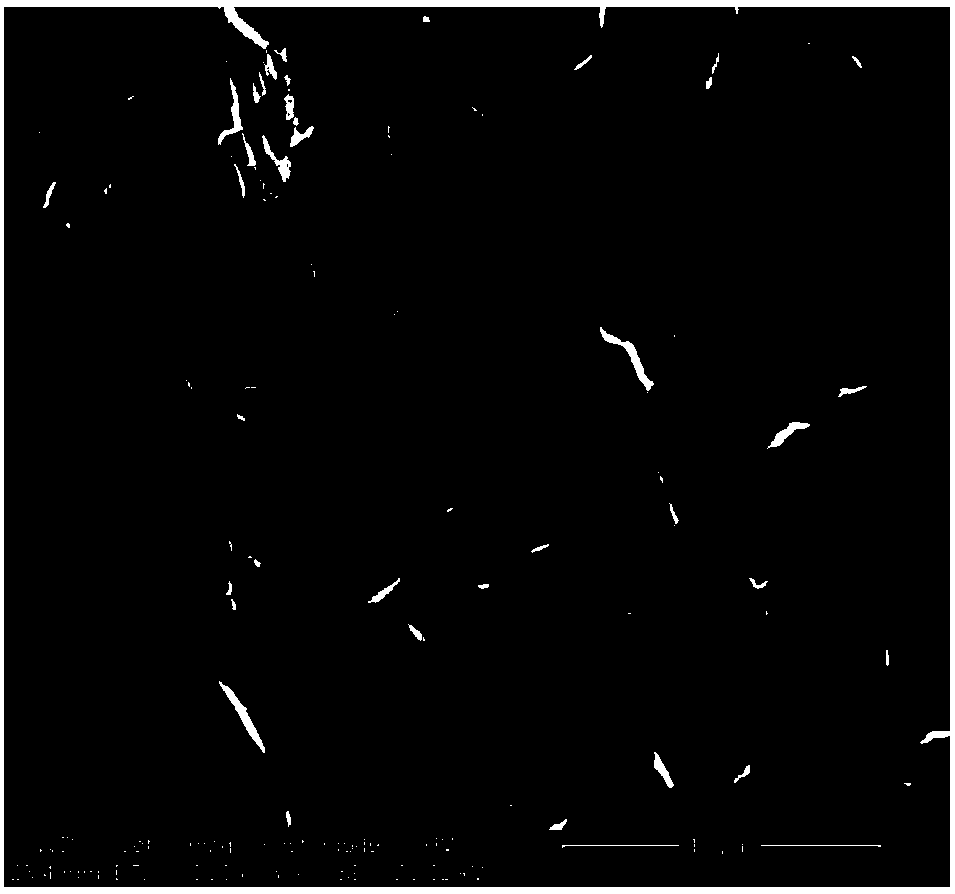

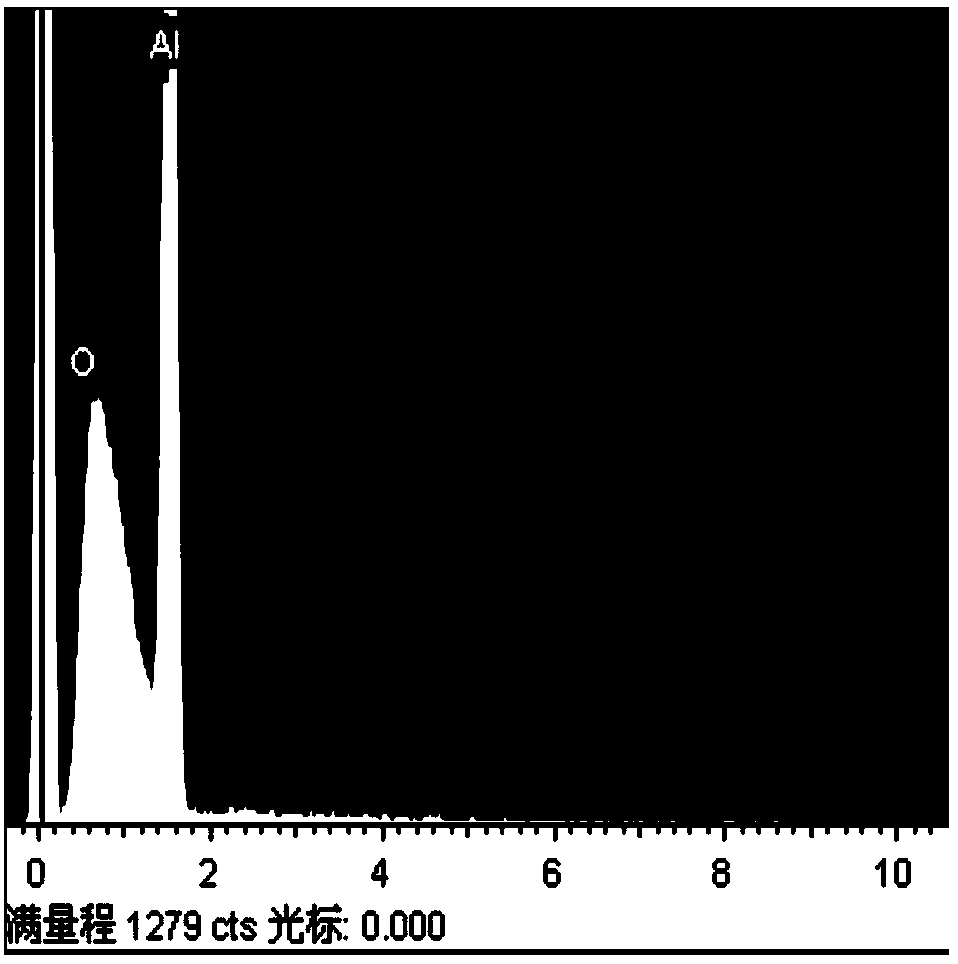

Image

Examples

Embodiment 1

[0037] The composition of the electrolyte and the steps of the electroplating aluminum method are as follows:

[0038] (1) Electrolyte configuration:

[0039] Configure AlCl with a molar ratio of 2:1 3 : EMIC (aluminum chloride-1-ethyl-3-methylimidazole chloride) room temperature ionic liquid is the electrolyte, and its preparation process is as follows:

[0040] ① Weighing. Weigh 200gEMIC, 365gAlCl respectively 3 .

[0041] ② preparation. AlCl 3 Add the powder to the EMIC powder in portions with constant stirring until all is dissolved.

[0042] ③ refined. Wash the high-purity aluminum wire with acid and alkali, then wash it with alcohol, dry it, put it in the prepared ionic liquid, and let it stand at room temperature for a week. The ionic liquid becomes clear and transparent, and you can try plating.

[0043] All processes were carried out in a glove box under an argon atmosphere.

[0044] AlCl 3 : The following reaction occurs when EMIC ionic liquid is configured...

Embodiment 2

[0057] Prepare aluminum coating on the surface of AM60 magnesium alloy, the composition of electrolyte and the step of electroplating aluminum method are as follows:

[0058] (1) Electrolyte configuration:

[0059] Configure AlCl with a molar ratio of 1.5:1 3 : EMIC (aluminum chloride-1-ethyl-3-methylimidazole chloride) room temperature ionic liquid is the electrolyte, and its preparation process is as follows:

[0060] ① Weighing. Weigh 250gEMIC, 342gAlCl respectively 3 .

[0061] ② preparation. AlCl 3 Add the powder to the EMIC powder in portions with constant stirring until all is dissolved.

[0062] ③ refined. Wash the high-purity aluminum wire with acid and alkali, then wash it with alcohol, dry it, put it in the prepared ionic liquid, and let it stand at room temperature for a week. The ionic liquid becomes clear and transparent, and you can try plating.

[0063] All processes were carried out in a glove box under an argon atmosphere.

[0064] AlCl 3 : The reac...

Embodiment 3

[0070] Prepare aluminum coating on the surface of AM60 magnesium alloy, the composition of electrolyte and the step of electroplating aluminum method are as follows:

[0071] (1) Electrolyte configuration:

[0072] Configure AlCl with a molar ratio of 1.2:1 3 : EMIC (aluminum chloride-1-ethyl-3-methylimidazole chloride) room temperature ionic liquid is the electrolyte, and its preparation process is as follows:

[0073] ① Weighing. Weigh 300gEMIC, 328gAlCl respectively 3 .

[0074] ② preparation. AlCl 3 Add the powder to the EMIC powder in portions with constant stirring until all is dissolved.

[0075] ③ refined. Wash the high-purity aluminum wire with acid and alkali, then wash it with alcohol, dry it, put it in the prepared ionic liquid, and let it stand at room temperature for a week. The ionic liquid becomes clear and transparent, and you can try plating.

[0076] All processes were carried out in a glove box under an argon atmosphere.

[0077] AlCl 3 : The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com