A method for preparing porous nano-silicon carbide using silicate glass as raw material

A technology of silicate glass and nano-silicon carbide, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult to obtain porous structure, harsh reaction conditions and high cost , to achieve considerable economic effects, safe response, and sufficient response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the nano-silicon carbide is as follows: mix silicate glass, magnesium powder, carbon source and molten salt, and heat it to 600-750°C for 1-12 hours at a heating rate of 1-30°C / min under an inert atmosphere. After the product is cooled to room temperature with the furnace, it is acid-washed to obtain nano-silicon carbide.

[0039] Among them, the silicate glass is sodium silicate glass or calcium silicate glass; the molten salt is magnesium halide, including magnesium chloride, magnesium bromide or magnesium iodide, preferably magnesium chloride; coal tar is selected as the carbon source; silicate glass, magnesium powder , the molten salt and the carbon source are mixed according to a mass ratio of 1:(0.5-0.8):(5-8):(0.5-2).

[0040] Specifically, the preparation method includes the following steps:

[0041] (1) mechanically ball-milling the silicate glass into glass powder after cleaning to obtain powdered silicate glass;

[0042] (2) Mix th...

Embodiment 1

[0058] A preparation method for preparing porous nano-silicon carbide using silicate-based glass as a raw material is carried out according to the following steps:

[0059] (1) 5g silicate glass is mechanically ball-milled into powder after cleaning;

[0060] (2) Ball milled silicate glass powder, magnesium powder, molten salt (MgCl 2 ), coal tar is ball milled and mixed evenly according to the mass ratio of 1:0.6:8:1;

[0061] (3) Then put the mixture into a tube furnace and heat it to 650° C. for 3 hours at a heating rate of 5° C. / min. After the product is cooled to room temperature with the furnace, take it out;

[0062] (4) The obtained product was first washed in 1 mol / L hydrochloric acid for 1 hour, then washed in hydrofluoric acid with a mass fraction of 5% for 3 hours, filtered by suction and dried to obtain porous silicon carbide nanoparticles.

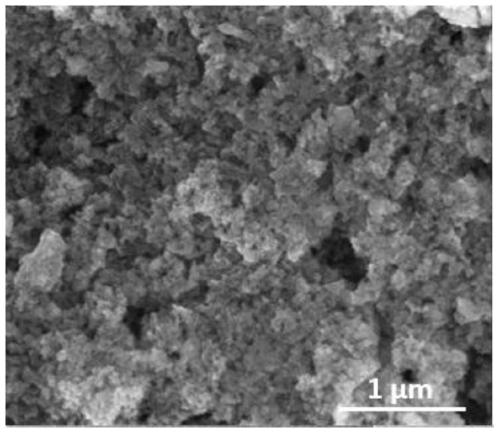

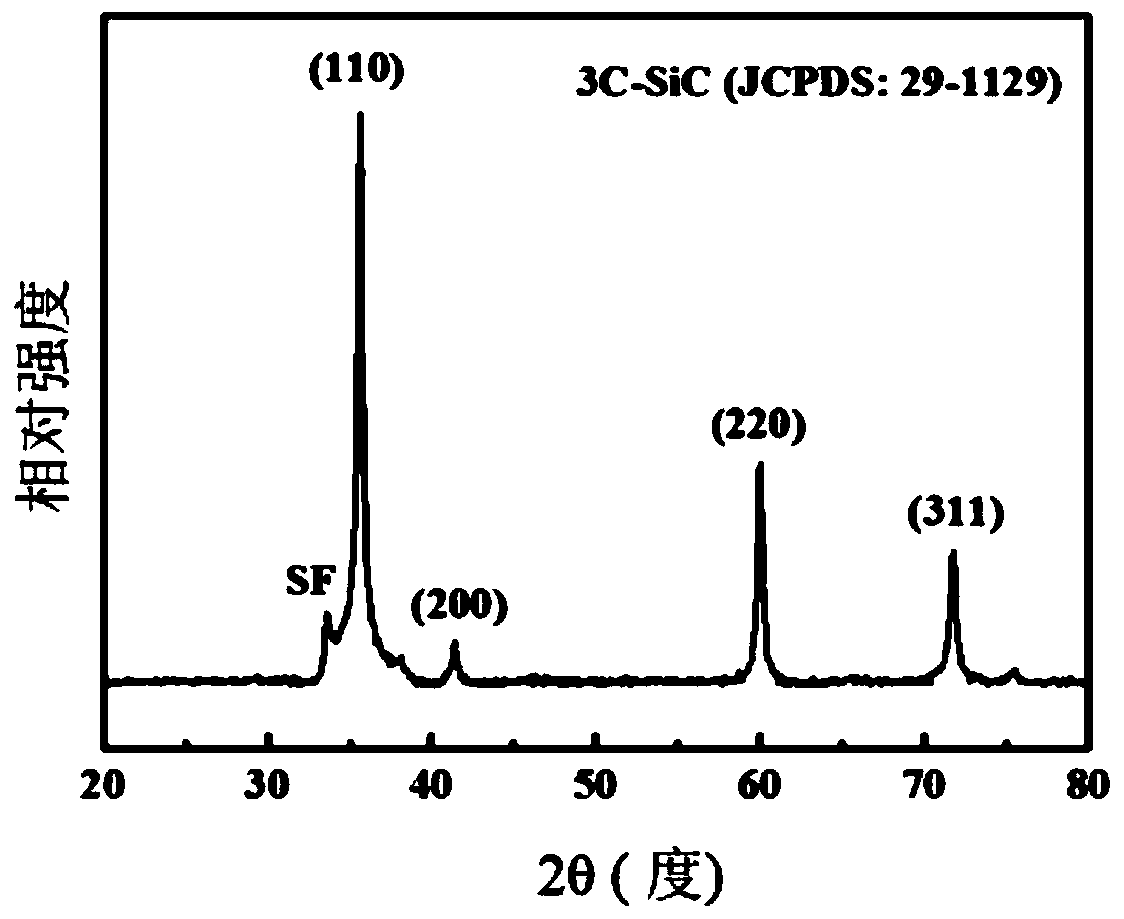

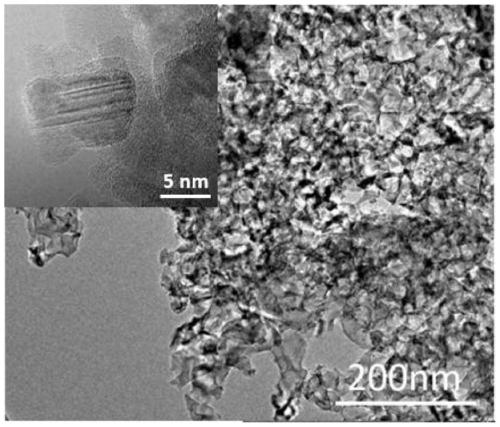

[0063] Characterization and analysis of the prepared porous nano-silicon carbide particles:

[0064] Depend on figure 1...

Embodiment 2

[0068] A preparation method for preparing porous nano-silicon carbide using silicate-based glass as a raw material is carried out according to the following steps:

[0069] (1) 5g silicate glass is mechanically ball-milled into powder after cleaning;

[0070] (2) Ball milled silicate glass powder, magnesium powder, molten salt (MgCl 2 ), coal tar is ball milled and mixed evenly according to the mass ratio of 1:0.6:7:1;

[0071] (3) Then put the mixture into a tube furnace and heat it to 600°C for 12 hours at a heating rate of 1°C / min, and take it out after the product is cooled to room temperature with the furnace;

[0072] The obtained product was first washed in 1 mol / L hydrochloric acid for 1 hour, then washed in hydrofluoric acid with a mass fraction of 5% for 3 hours, filtered by suction and dried to obtain porous silicon carbide nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com