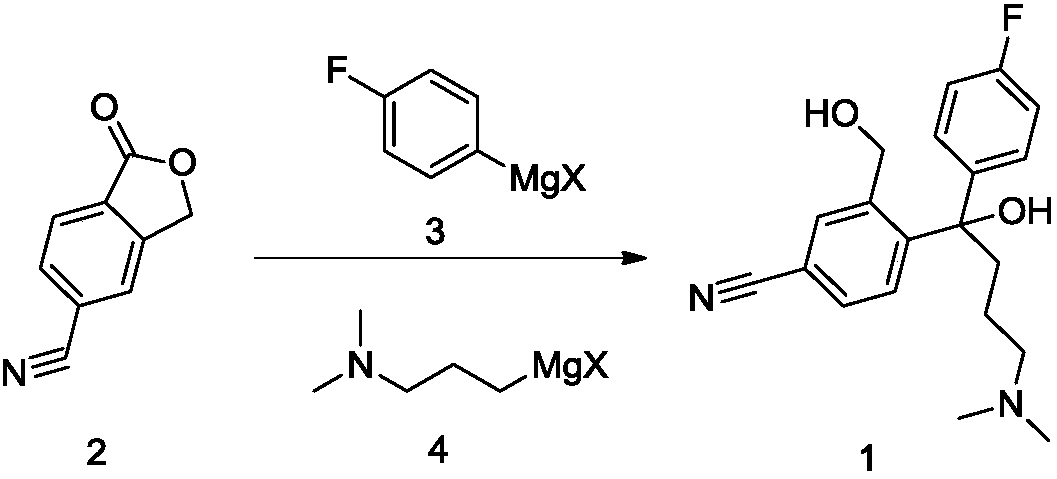

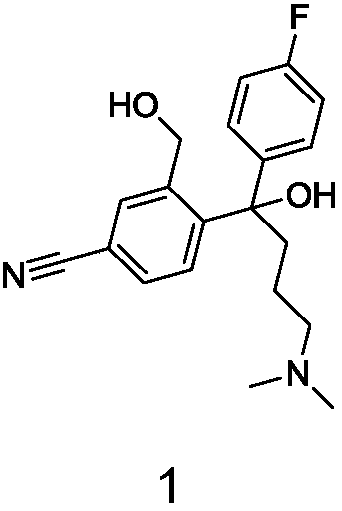

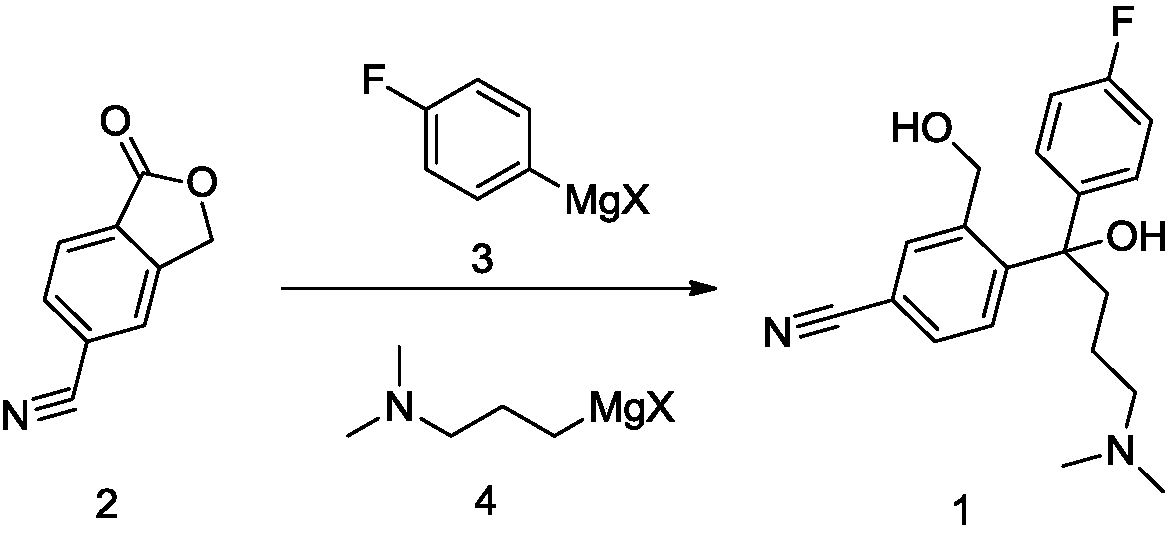

Method for continuously preparing citalopram diol

A technology of cyanodiol and cyanophthalide, which is applied in the field of continuous preparation of 5-cyanodiol, can solve the problems of not being able to control the formation of main impurities, unsatisfactory yield, and low production yield, and achieve the production process Simple and controllable, reducing the risk of reaction, and easy to industrialize the effect of amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Prepare feed solution A: 5-cyanophthalide tetrahydrofuran solution, concentration 0.23mmol / g;

[0038] Preparation of material solution B: Grignard reagent tetrahydrofuran solution, the concentration of raw material 3 is 0.19mmol / g, and the concentration of raw material 4 is 0.20mmol / g;

[0039] (2) Control the temperature of the microreactor at 10°C, and continuously transport the feed liquid B of the feed liquid A in step (1) into the microreactor at 12.0g / min and 15g / min respectively, with a residence time of 2.6min, at the end of the reactor The outlet is quenched with a saturated ammonium chloride solution, and the sample is detected to obtain the HPLC detection result of the reaction solution, and the results are shown in Table 2;

[0040] (3) Concentrate, extract, acidify, crystallize the quenched reaction solution in step (2), and finally centrifuge and dry to obtain 5-cyanodiol hydrochloride with a yield of 89.38%.

Embodiment 2

[0042] (1) Prepare feed solution A: 2-methyltetrahydrofuran solution of 5-cyanophthalide, concentration 0.50mmol / g;

[0043] Prepare material solution B: Grignard reagent ether solution, raw material 3 concentration 0.33mmol / g, raw material 4 concentration 0.33mmol / g;

[0044] (2) control microreactor temperature 3 ℃, feed liquid B in step (1) feed liquid A enters microreactor continuously with 15.0g / min and 23.0g / min respectively, residence time 3.2min, in reactor The terminal outlet was quenched with a saturated ammonium chloride solution, and a sample was taken for detection to obtain the HPLC detection result of the reaction solution, and the results are shown in Table 2;

[0045] (3) Concentrate, extract, acidify, crystallize the quenched reaction solution in step (2), and finally centrifuge and dry to obtain 5-cyanodiol hydrochloride with a yield of 88.74%.

Embodiment 3

[0047] (1) Prepared material solution A: 5-cyanophthalide toluene solution, concentration 0.30mmol / g; prepared material solution B: Grignard reagent 2-methyltetrahydrofuran solution, raw material 3 concentration 0.36mmol / g, raw material 4 concentration 0.26 mmol / g;

[0048] (2) Control microreactor temperature 80 ℃, feed liquid B in step (1) feed liquid A enters microreactor continuously with 8.0g / min and 18.0g / min respectively, residence time 0.9min, in reactor The terminal outlet was quenched with a saturated ammonium chloride solution, and a sample was taken for detection to obtain the HPLC detection result of the reaction solution, and the results are shown in Table 2;

[0049] (3) Concentrate, extract, acidify, crystallize the quenched reaction solution in step (2), and finally centrifuge and dry to obtain 5-cyanodiol hydrochloride with a yield of 88.26%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com