A cooling system for hydrogen energy tram fuel cell

A fuel cell and cooling system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of high heat dissipation requirements, high rated power of hydrogen fuel cells, and affecting the service life of hydrogen fuel cell reaction exchange membranes, etc. problem, achieve the effect of ensuring the cooling effect and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

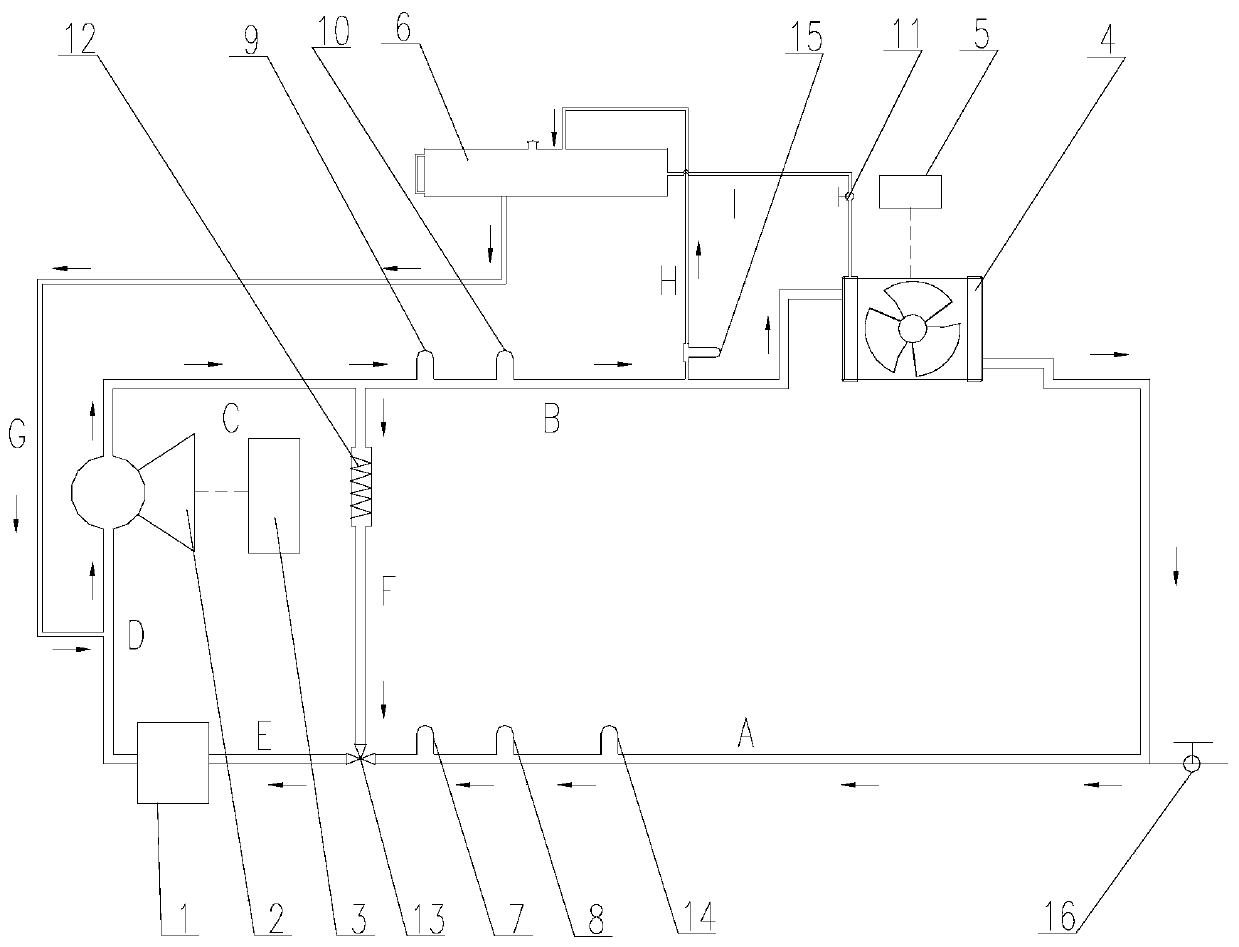

[0032] Such as figure 1 As shown, the present invention provides a cooling system for a hydrogen energy tram fuel cell, including a cooling cycle formed by sequentially connecting the hydrogen fuel cell 1, a circulation device and a cooling device through pipelines;

[0033] The cooling system also includes an electric heating tube 12, the electric heating tube 12 communicates with the circulation device through a pipeline at one end, and communicates with the hydrogen fuel cell 1 through a pipeline at the other end, forming a heating circulation loop.

[0034] Specifically, the hydrogen fuel cell 1 in this embodiment generates electric energy, and hydrogen and oxygen in the air react to generate electricity and water under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com