Process of preparing portland cement with waste ceramic tile polishing material

A technology of ceramic polished bricks and Portland cement, which is applied in the direction of cement production, etc., can solve the problems of difficult sustainable development of the cement industry, shortage of natural resources, ecological environment pollution, etc., and achieve the goal of protecting farmland, saving natural resources and reducing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

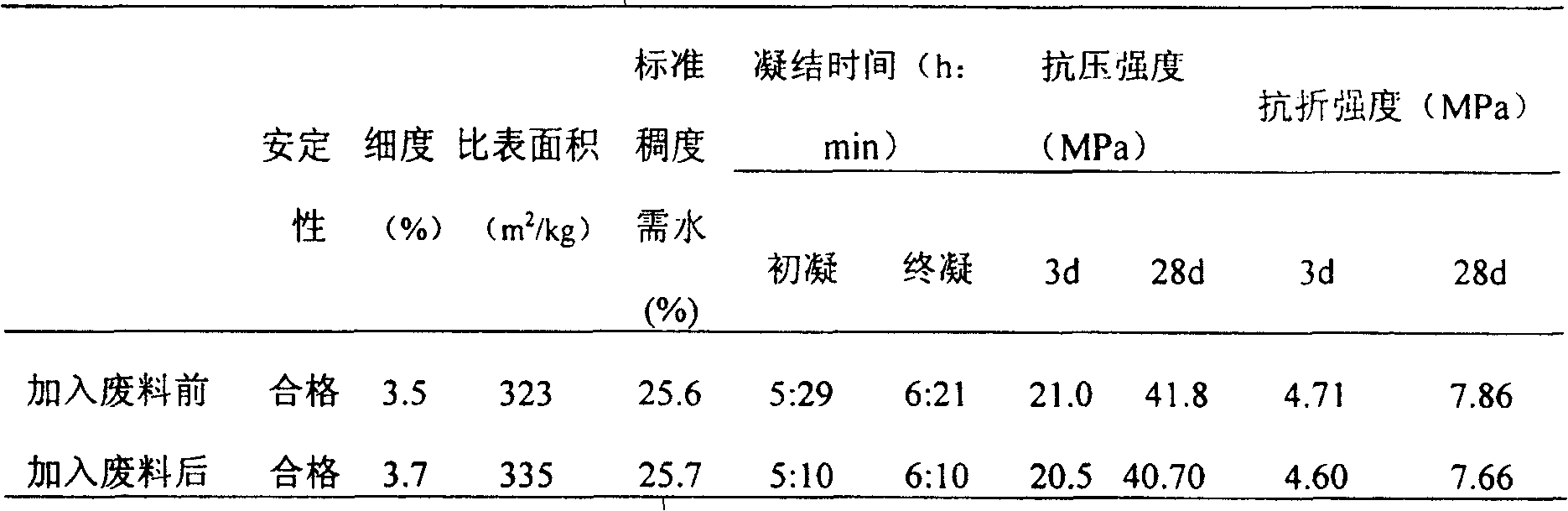

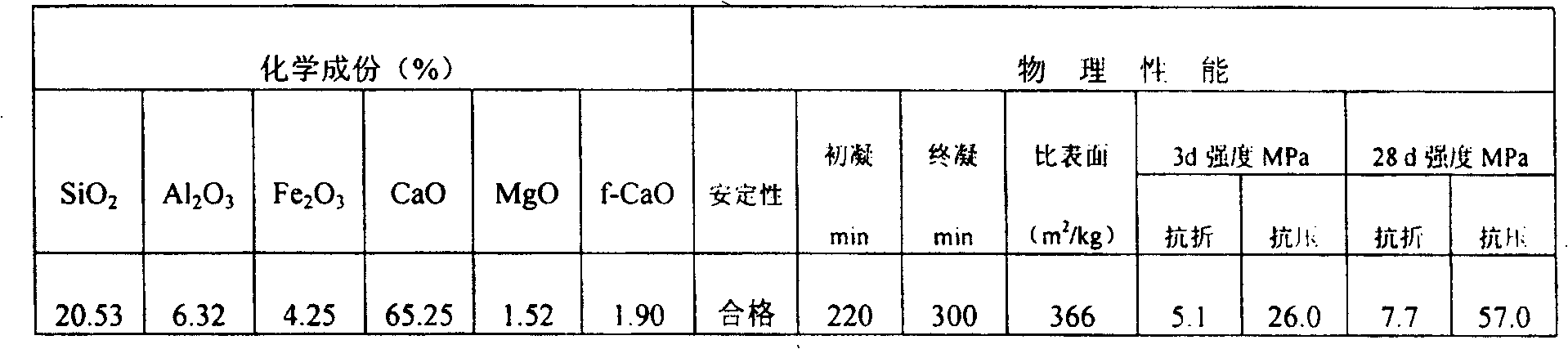

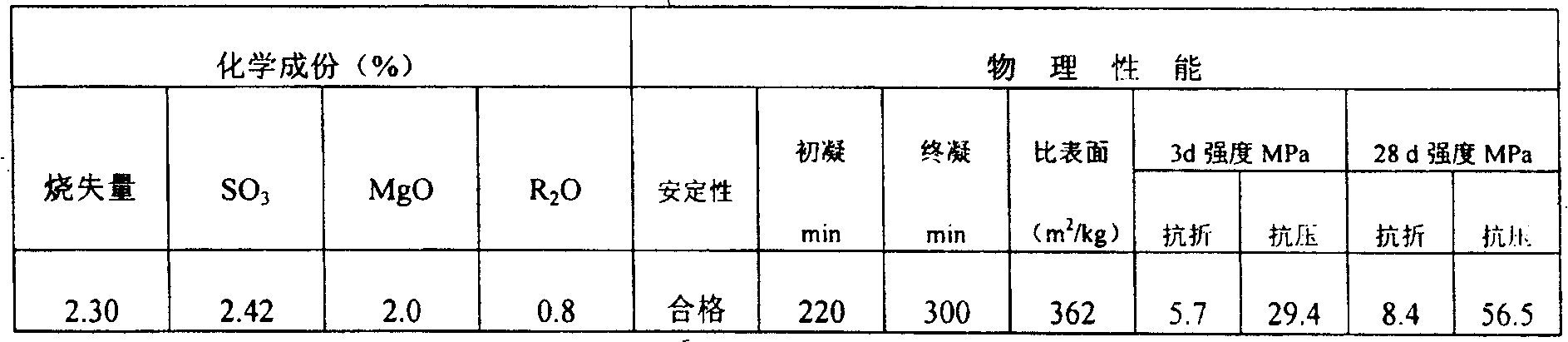

Embodiment 1

[0037] The method for preparing portland cement by utilizing ceramic polished brick waste materials comprises the steps of:

[0038] (1) Pretreatment of ceramic polished tile waste: First, the ceramic polished tile waste that has been dried in the sun and contains about 20% water from the ceramic polished tile factory is first ground in the equipment of the roller press, and then sieved to remove large Block or fibrous impurities make it a non-cohesive, fluid and uniform powder.

[0039] (2) Pretreat the ceramic polished tile waste according to step (1) to make it a non-bonding, fluid and uniform powder, replace about 25% of the clay raw material ingredients, and make the ceramic polished tile Waste: Limestone: Clay: Iron Calibration raw material: Fluorite: Phosphogypsum: Anthracite is made into cement raw meal according to the weight ratio of 2.5:76.0:5.2:3.1:0.8:2.5:12, and the cement raw meal saturation ratio KH is controlled to be 0.91 ~0.94, silicic acid rate N is 1.90~2...

Embodiment 2

[0046] The method for preparing portland cement by utilizing ceramic polished brick waste materials comprises the steps of:

[0047] (1) Pretreatment of ceramic polished tile waste: First, the ceramic polished tile waste that has been dried in the sun and contains about 20% water from the ceramic polished tile factory is first ground in the equipment of the roller press, and then sieved to remove large Block or fibrous impurities make it a non-cohesive, fluid and uniform powder.

[0048] (2) Replace 25% of the clay raw material with the pretreated ceramic polished tile waste as previously described, and use the ceramic polished tile waste: limestone: clay: iron correction raw material: fluorite: phosphogypsum: anthracite by 2.0: 75.0: 4.5 : 3.0: 0.7: 2.0: 11 weight ratio to make cement raw meal, control the cement raw meal saturation ratio KH is 0.91 ~ 0.94, the silicic acid rate N is 1.90 ~ 2.05 and the aluminum oxygen rate P is 1.4 ~ 1.6. The ball forming disc is made into ...

Embodiment 3

[0055] The method for preparing portland cement by utilizing ceramic polished brick waste materials comprises the steps of:

[0056] (1) Pretreatment of ceramic polished tile waste: First, the ceramic polished tile waste that has been dried in the sun and contains about 20% water from the ceramic polished tile factory is first ground in the equipment of the roller press, and then sieved to remove large particles. Block or fibrous impurities make it a non-cohesive, fluid and uniform powder.

[0057] (2) Replace 25% of the clay raw material with the pretreated ceramic polished tile waste as previously described, and use the ceramic polished tile waste: limestone: clay: iron correction raw material: fluorite: phosphogypsum: anthracite according to 3.0: 77: 5.8 : 3.2: 0.9: 3.0: 13 weight ratio to make cement raw meal, control the cement raw meal saturation ratio KH is 0.91 ~ 0.94, the silicic acid rate N is 1.90 ~ 2.05 and the aluminum oxygen rate P is 1.4 ~ 1.6. The ball forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com