Active admixture and preparation method thereof

A technology for active admixtures and raw materials, which is applied in the field of active admixtures and their preparation, can solve the problems of not being able to solve environmental protection problems well, enterprise enthusiasm, complicated product preparation processes, and imperfect utilization technologies, etc. Stable product performance and low activation temperature in medium heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

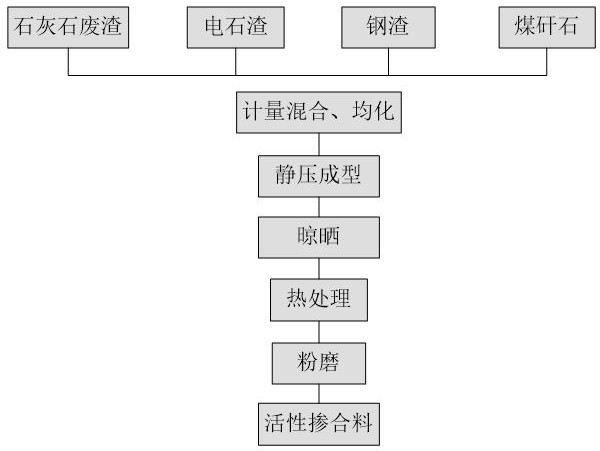

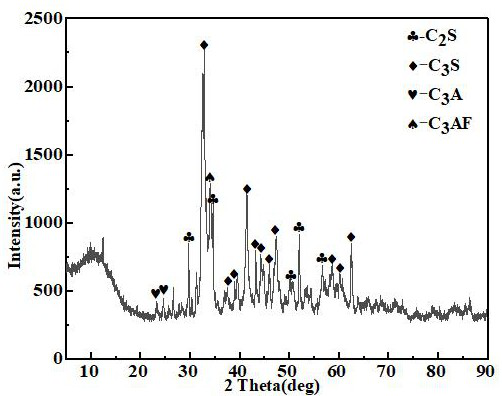

[0029] Embodiment 1: as figure 1 , 2 As shown, the active admixture is an active admixture made by pulverizing, mixing, pressing, heat-treating, and grinding the raw materials in the following mass percentages: limestone waste slag 45wt%, carbide slag 5wt%, steel slag 20wt%, coal gangue 30wt%. Limestone waste slag, steel slag, and coal gangue are crushed to pass 100 mesh and the sieve residue is less than 5%.

[0030] The preparation method of active admixture of the present invention, concrete preparation steps are as follows:

[0031] (1) Raw material pretreatment: Limestone waste slag, calcium carbide slag, steel slag, and coal gangue are respectively taken as raw materials, and the limestone waste slag, steel slag, and coal gangue are respectively crushed to pass 100 mesh and the sieve residue is less than 5%.

[0032] (2) Static pressure molding: Weigh the raw materials processed in step (1) according to the mass percentage, mix them evenly, put them into the static pre...

Embodiment 2

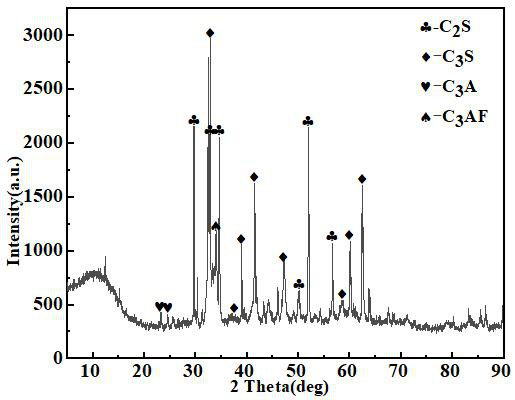

[0040] Embodiment 2: as figure 1 , 3 As shown, the active admixture is an active admixture made by pulverizing, mixing, pressing, heat-treating, and grinding the raw materials in the following mass percentages: limestone waste slag 50wt%, carbide slag 8wt%, steel slag 15wt%, coal gangue 27wt%. Limestone waste slag, steel slag, and coal gangue are crushed to 100 mesh, and the sieve residue is less than 5%.

[0041] The preparation method of active admixture of the present invention, concrete preparation steps are as follows:

[0042] (1) Raw material pretreatment: Limestone waste slag, calcium carbide slag, steel slag, and coal gangue are respectively taken as raw materials, and the limestone waste slag, steel slag, and coal gangue are respectively crushed to 100 mesh, and the sieve residue is less than 5%.

[0043] (2) Static pressure molding: Weigh the raw materials processed in step (1) according to the mass percentage, mix them evenly, put them into the static pressure mo...

Embodiment 3

[0051] Embodiment 3: as figure 1 , 4 As shown, the active admixture is an active admixture obtained by pulverizing, mixing, pressing, heat-treating, and grinding raw materials in the following mass percentages: limestone waste slag 60wt%, carbide slag 10wt%, steel slag 10wt%, and coal gangue 20wt%. Limestone waste slag, steel slag, and coal gangue are crushed to 100 mesh, and the sieve residue is less than 5%.

[0052] The preparation method of active admixture of the present invention, concrete preparation steps are as follows:

[0053] (1) Raw material pretreatment: Limestone waste slag, calcium carbide slag, steel slag, and coal gangue are respectively taken as raw materials, and the limestone waste slag, steel slag, and coal gangue are respectively crushed to 100 mesh, and the sieve residue is less than 5%.

[0054] (2) Static pressure molding: Weigh the raw materials processed in step (1) according to the mass percentage, mix them evenly, put them into the static pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com