Method for joining second-generation high-temperature superconducting wires by melting diffusion

A high-temperature superconducting and melting diffusion technology, applied in superconducting devices, superconducting parts, superconducting/high-conducting conductors, etc., can solve problems such as pollution and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described in detail through preferred embodiments below. Those skilled in the art should understand that the following examples are only used to specifically illustrate the present invention rather than limit the present invention. When describing the present invention in detail, the same reference numerals are assigned to the same parts, and repeated description thereof will be omitted.

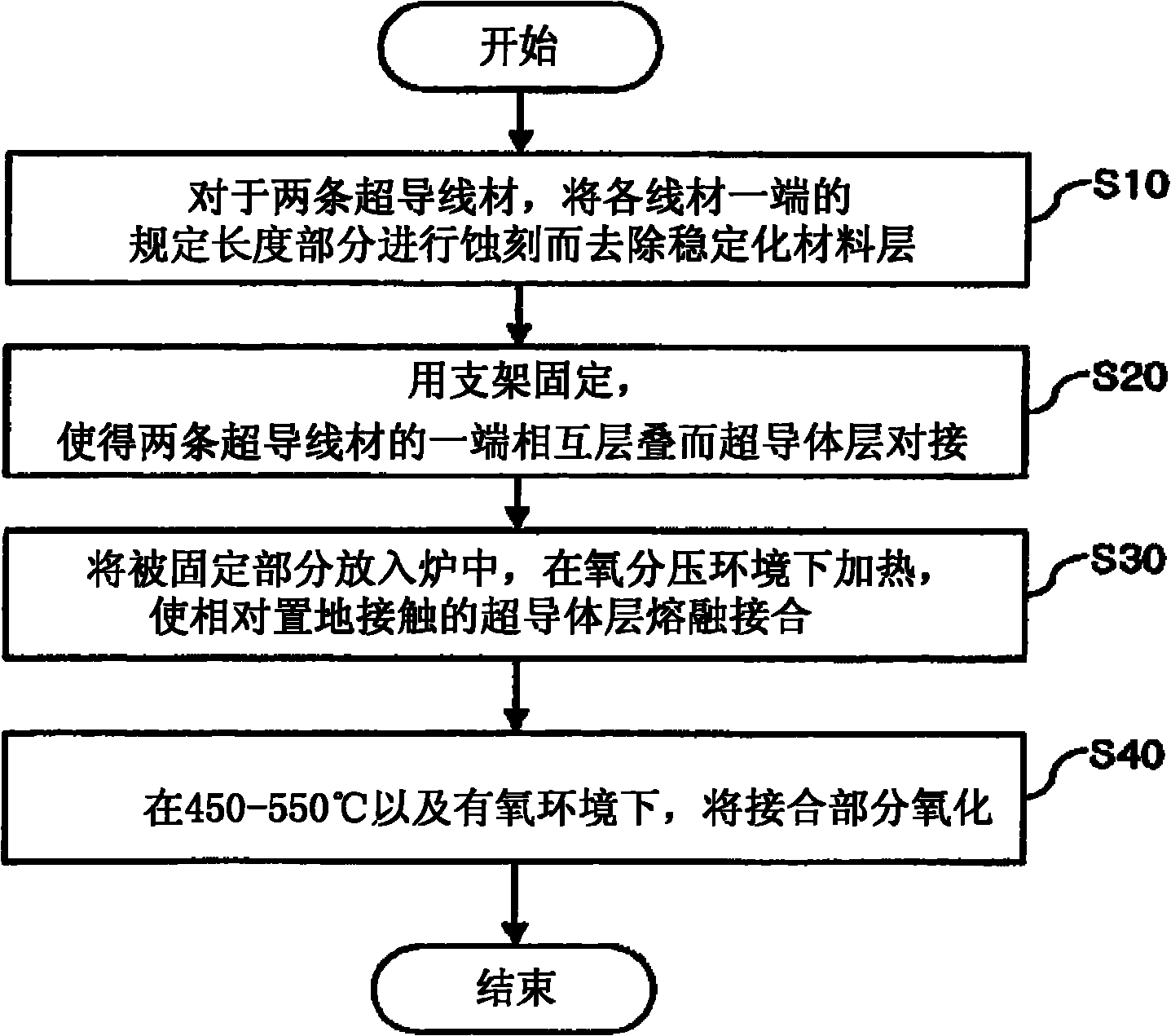

[0047] image 3 It is a flow chart illustrating a method of fusion-diffusion bonding of second-generation high-temperature superconducting wires by adjusting oxygen partial pressure in an embodiment of the present invention.

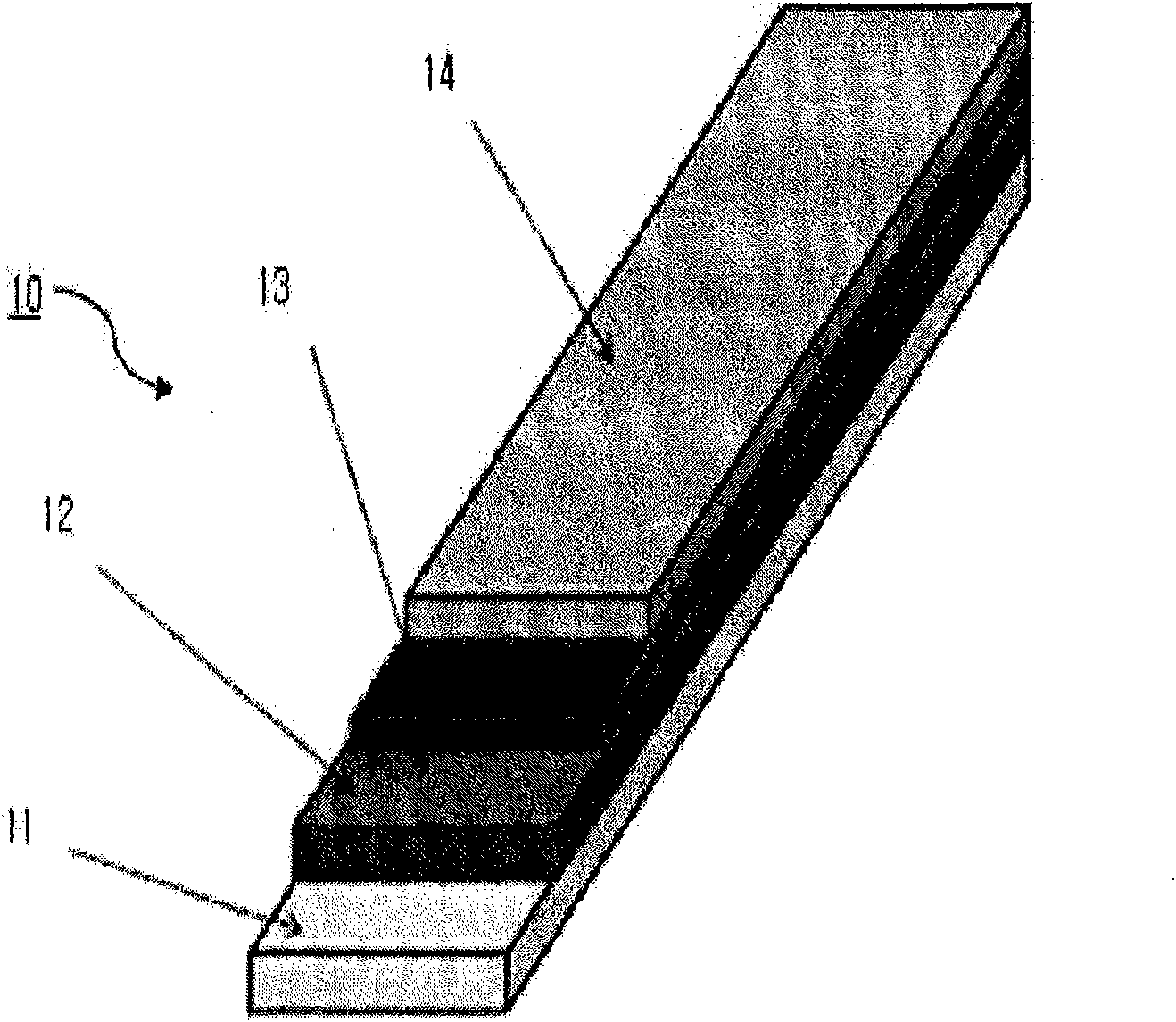

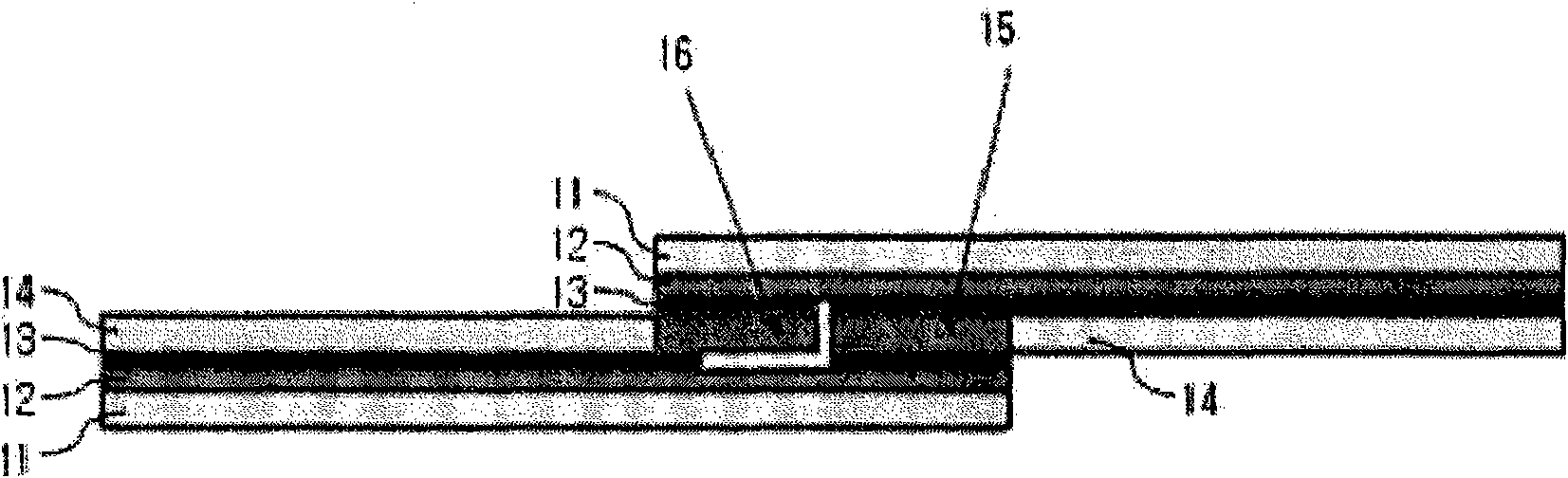

[0048] Figure 4 It is a diagram illustrating a second-generation high-temperature superconducting wire (YBCO-CC) after removing a stabilizing material layer from one end of the superconducting wire in an embodiment of the present invention. In one embodiment of the present invention, the second generation high temperature sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com