Novel energy-saving consumption-reducing dry-process cement clinker and preparation method thereof

A dry-process cement and cement clinker technology, which is applied in the field of cement clinker, can solve the problems of long firing time, slow solid-phase reaction speed, high firing temperature, etc., shorten the firing time, reduce the liquid phase viscosity, and shorten the The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

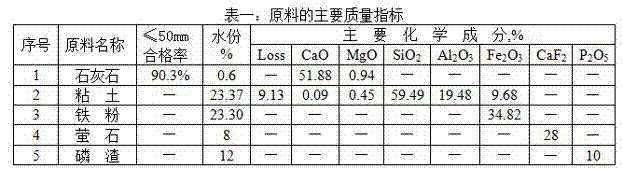

[0057] Step 2 of Example 10 is based on Step 2 of Examples 1 to 9, adding fluorite, or waste slag of fluorite, mixed with limestone, clay and iron powder to form dry raw meal powder, so that the clinker Calcium fluoride (CaF 2 ) composition, the specific weight percentage of fluorite and the added calcium fluoride (CaF 2 ) see Table 3 and Table 4 for the specific content;

Embodiment 11

[0058] Step 2 of Example 11 is based on Step 2 of Examples 1 to 9, and then add phosphorus slag, which is mixed with limestone, clay and iron powder and ground into dry raw meal powder, in order to increase P in the clinker. 2 o 5 composition, the specific weight percentage of phosphorus slag and the added P 2 o 5 See Table 3 and Table 4 for the specific content;

Embodiment 12

[0059] Step 2 of Example 12 is based on Step 2 of Examples 1 to 9, while adding fluorite and phosphorus slag. They are mixed with limestone, clay and iron powder and ground into dry raw meal powder. Their specific weight percentages and CaF 2 ,P 2 o 5 See Table 3 and Table 4 for the specific content;

[0060] (3) The dry raw meal powder obtained in step (2) enters the homogenization storehouse and is then sent to the preheater after being homogenized. After preheating, the temperature rises to 860-880°C and then enters the calciner. The decomposed raw meal enters the rotary kiln , Calcined clinker at 1300~1400°C for 30~40 minutes.

[0061] It can be known from Table 4 that the examples 10-12 not only have the best coal-saving effect, but also have the best strength index of cement clinker.

[0062]

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com