Waste lead-acid storage battery and lead-containing waste regenerated reduced lead ingredient and preparation method

A technology for waste lead-acid batteries and waste materials, which is applied in the field of lead-zinc smelting and secondary lead metallurgy, can solve the problems of tight supply in the iron filing market, high prices, and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

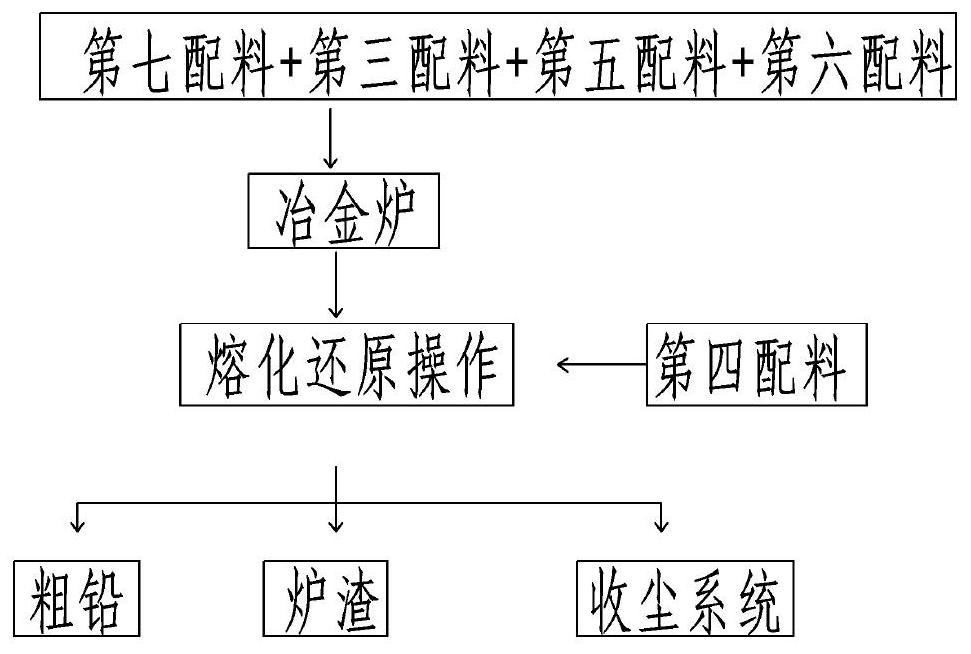

[0035] Basic as attached figure 1 Shown: a method for preparing waste lead-acid batteries and regenerated and reduced lead from lead-containing waste, comprising the following steps:

[0036] A. Ingredients, prepare iron filings, coal, iron ore slag, coke particles, return slag and main ingredients in advance; name the iron filings as the first ingredient, and the coal as the second ingredient, and the coal is white coal or anthracite; the second The mixture of the first ingredient and the second ingredient is named the third ingredient. The first ingredient and iron ore slag are mixed and named as the fourth ingredient, and the iron ore slag is pyrite slag. Scorched particles are named as the fifth ingredient, the returned slag is named as the sixth ingredient, and the main ingredient is named as the seventh ingredient. The main materials are wastes containing lead and lead compounds, including lead mud, lead paste, waste plates and other wastes. Return slag refers to the ...

Embodiment 2

[0043] The difference between this embodiment and Example 1 is that the amount of ingredients in step A is different. In this embodiment, 10 tons of the seventh ingredient is prepared; the third ingredient is prepared, accounting for 9% of the seventh ingredient, i.e. 900 kg. Among the third ingredients, the first ingredient accounts for 1 part, and the second ingredient accounts for 3 parts; the fifth ingredient is prepared, accounting for 1% of the seventh ingredient, that is, 100 kg; the sixth ingredient is prepared, accounting for 1% of the seventh ingredient, that is 100 kg. Prepare the fourth batch, which accounts for 3% of the seventh batch, i.e. 300 kilograms, wherein the first batch accounts for 9.5 parts in the fourth batch, and the iron ore slag accounts for 0.5 part.

[0044] 6.1 tons of reduced lead ingots were obtained by putting into the furnace, the water-reducing direct recovery rate reached 68.5%, and the total recovery rate reached 98.8%.

Embodiment 3

[0046] The difference between this embodiment and Example 1 is that the amount of ingredients in step A is different, and 10 tons of the seventh ingredient is prepared; the third ingredient is prepared, accounting for 9% of the seventh ingredient, that is, 900 kg, of which the third ingredient The first ingredient accounts for 1.8 parts, and the second ingredient accounts for 4 parts; prepare the fifth ingredient, which accounts for 1% of the seventh ingredient, or 100 kilograms; prepare the sixth ingredient, which accounts for 1% of the seventh ingredient, or 100 kilograms. Prepare the fourth batch, which accounts for 3% of the seventh batch, i.e. 300 kilograms, wherein the first batch accounts for 10 parts in the fourth batch, and the iron ore slag accounts for 0.1 part.

[0047] 6.04 tons of reduced lead ingots were obtained by putting into the furnace, the water-reduced direct recovery rate reached 70.2%, and the total recovery rate reached 97.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com