Thermally powered oxygen/nitrogen plant incorporating an oxygen selective ion transport membrane

An ion transfer membrane, a technology for selecting ions, applied in the direction of oxygen/ozone/oxide/hydroxide, oxygen preparation, membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

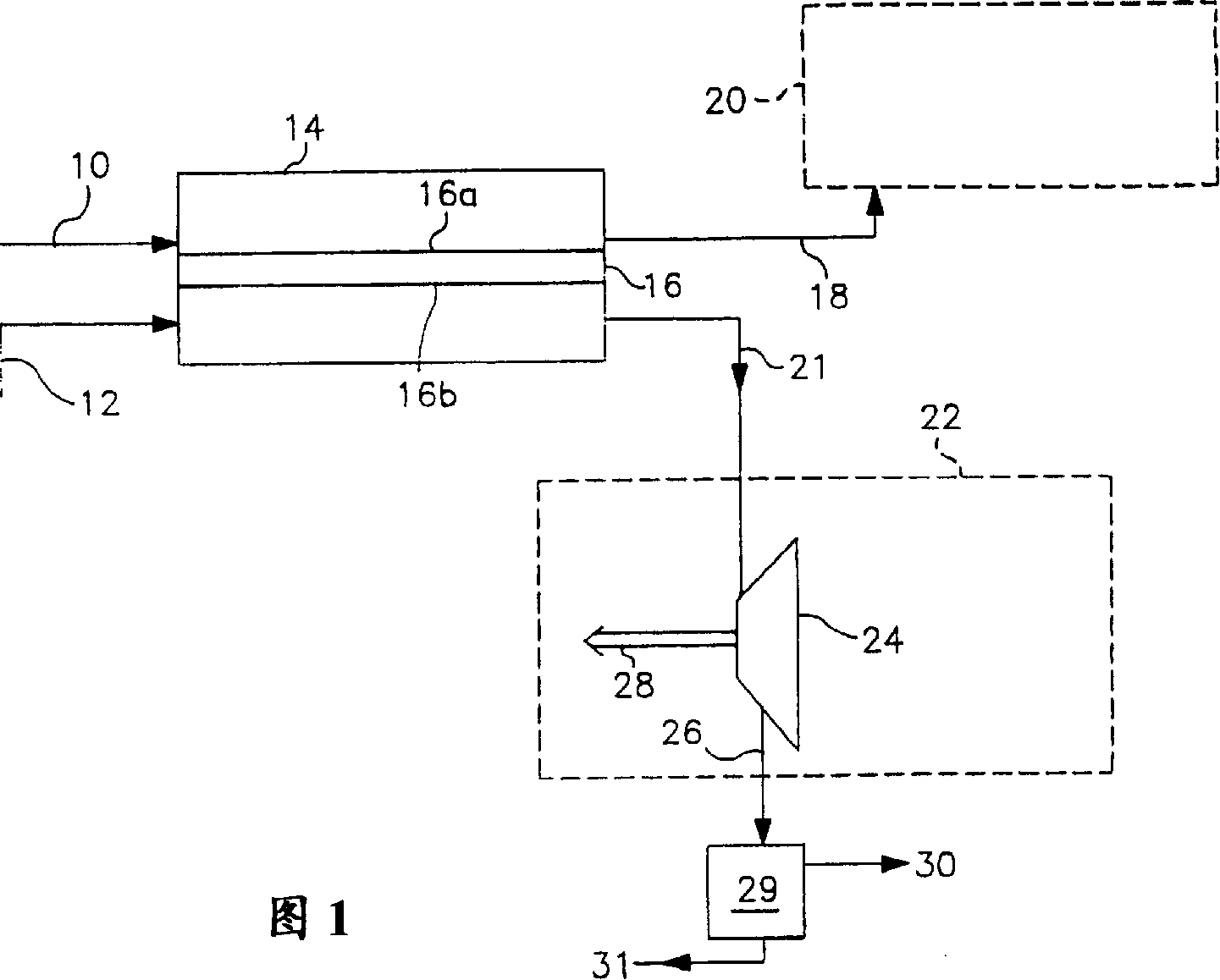

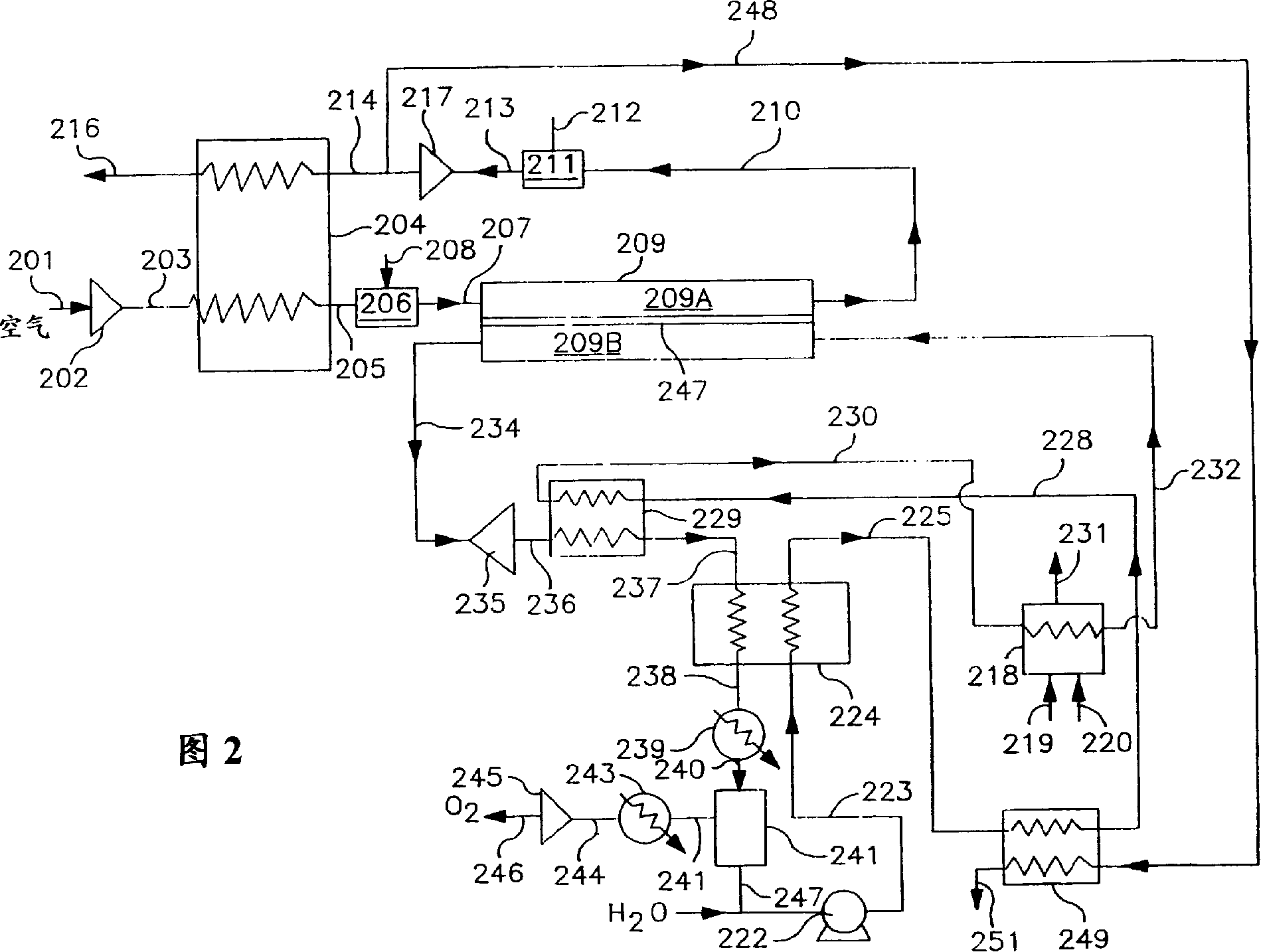

[0075] The following calculations were performed to compare the performance of three gas turbine cycles for simultaneous oxygen production: the system shown in Figure 2 of the present invention (case A); use of gas turbine exhaust to raise the temperature of the steam used to purge the permeate side of the ion transport generator, A cycle in which oxygen is delivered at elevated pressure (case B), and a gas turbine cycle with simultaneous oxygen production and no steam generation, where the turbine exhaust is used to regenerate preheated air (case C).

[0076] process conditions

[0077] Simultaneous production of oxygen: 1000 MNCFH

[0078] Air Compressor Discharge Pressure: 185 psia

[0079] Single-stage air compression AD. Eff=85%

[0080] Ion migration inlet temperature: 1650°F (900°C)

[0081] Turbine inlet pressure 180 psia

[0082] Turbine exhaust pressure 16 psia

[0083] Turbine Efficiency = 90%

[0084] Oxygen recovery rate: 5.6% of compressed air flow

[008...

Embodiment 2

[0110] Example 2 Oxygen Product: 1000 MNCFH at 145 psia Nitrogen Co-Product: 1670 MM NCFH Air Compressor Discharge Pressure: 155 psia Air Compression Stages: 4 (compressor driven by thermal expander, not gas turbine) Air Compressor Efficiency = 85% Hot Gas Turbine Inlet Pressure: 150 psia Hot Gas Turbine Inlet Temperature: 1750°F (955°C) Hot Gas Turbine Exhaust Pressure: 16 pisa Hot Gas Turbine Efficiency: 90% Ion Mobility Separator Inlet Temperature: 1650°F (900°C) Ion Transport Deoxygen Outlet Temperature: 1750°F Deoxygenated Fuel Dilution 79 MNCFH N 2 High pressure turbine inlet pressure: 1000 pisa High temperature turbine inlet temperature: 805°F (430°C) Low pressure turbine inlet pressure: 150 pisa Low pressure turbine inlet temperature: 1650°F Low pressure turbine exhaust gas pressure: 16 psia Turbine efficiency: 90% Steam condensing pressure: 14.7 Steam produced by pisa: 303 M lbs / Hr Result: Oxygen recovery: % of O in the feed air 2 83% of N under 145 pisa 2 Co-produc...

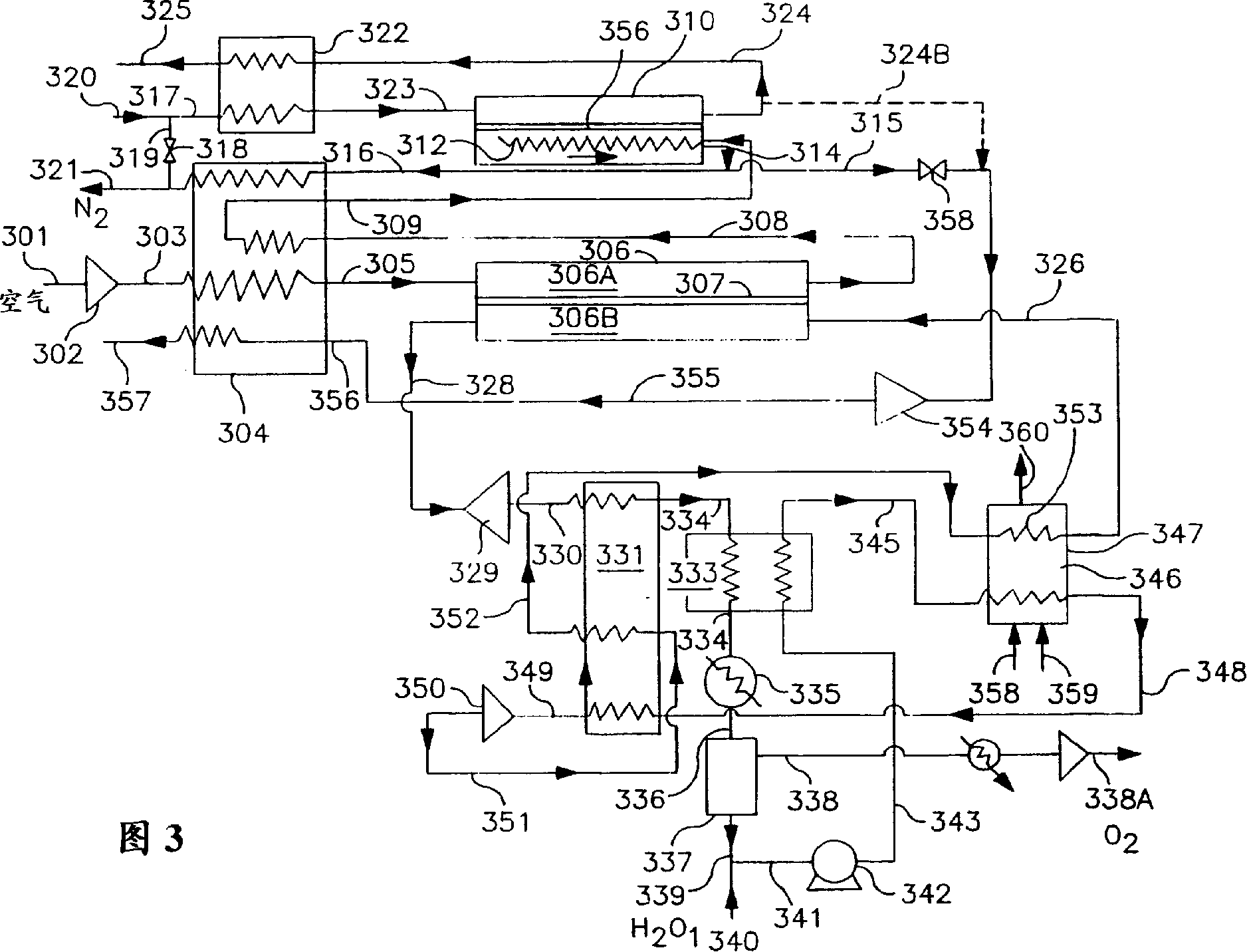

Embodiment 3

[0159] The following embodiment is to apply the process shown in Figure 4 and Figure 5 The reactor design shown is obtained assuming the following conditions:

[0160] Air Flow: 1130 MNCFH.

[0161] The air is compressed to 115 psia in 3 stages, which has a thermal insulation efficiency of 85%.

[0162] Flow into Reactor Separator Cooler:

[0163] 225 MNCFH at 120°F

[0164] 905 MNCFH, 400°F

[0165] Maximum Oxygen Transport Membrane (OTM) Operating Temperature: 1760°F

[0166] Average OTM separator driving force: log(PO 阴极 / PO 阳极 )=0.3

[0167] Nitrogen exits separator reactor cooler at 1300°F

[0168] Turbine Flow: 680 NCFH of N at 1300°F 2 .

[0169] Turbine Efficiency: 68%

[0170] Purge steam: 4.21 1bs / hr.

[0171] Fuel: 900 BTU / NCFH low calorific value natural gas

[0172] Fuel Consumption: 18900 NCFH

[0173] Product flow:

[0174] 200 MNCFH of oxygen (91.4% O 2 , 8.6% CO 2 ), 15 psia.

[0175] The nitrogen of 212 MNCFH (O 2 <10 ppm), 100 psia

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com