Air supplying device of blast furnace as well as combustion method and oxygen-enriching method of injected coal powder thereof

An air supply device and a blast furnace technology, which are applied in the blast furnace air supply device, blast furnace coal injection technology and blast furnace air supply field, can solve the problems of not becoming a practical technology, limited actual effect, and hindering blast furnace tuyere opening and blocking operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

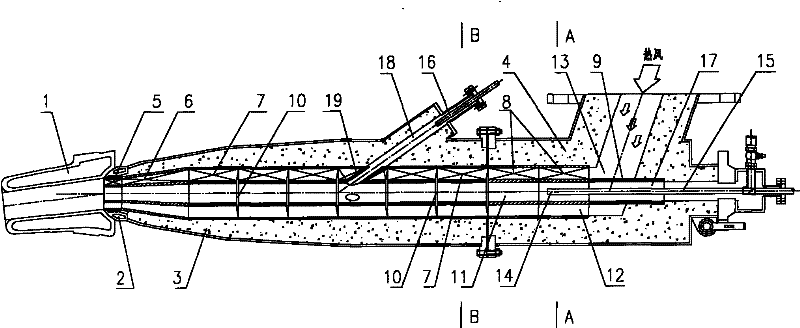

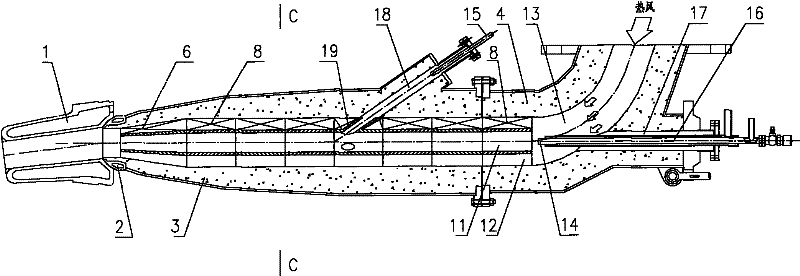

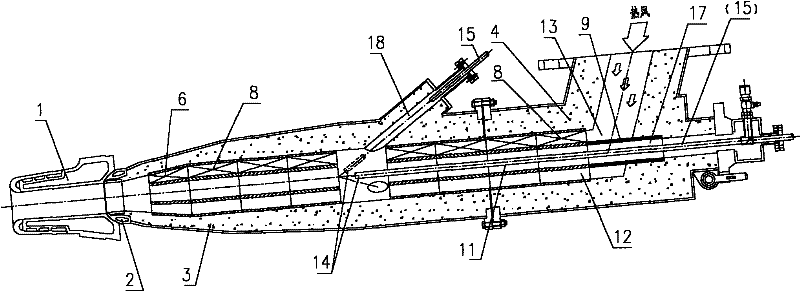

[0047] Such as figure 1 Among them, a blast furnace air supply device is composed of a straight blow pipe 3, an elbow 4 and pipe bricks 5, 6, 7, 8, and 9. The convex spherical end 2 of the straight blow pipe 3 in contact with the tuyere 1 is a water cooling structure. From the peephole channel 17 in the elbow 4 to the entire hot air channel 13 at the outlet of the straight blow pipe 3, use A, B, C, D, E type bricks 5, 6, 7, 8, 9 from the straight blow pipe 3 outlet in turn Start the masonry and build it until the peephole passage 17 of the elbow 4. Except for the E-type brick 9 which is a tube, the A, B, C, and D-type bricks 5, 6, 7, and 8 are all double-layered, and each has an inner tube 21 and an outer tube 22. Each of A, B, C, D type bricks 5, 6, 7, 8 are built according to the method of close contact between the outer tube 22 and the inner tube 21 aligned with each other. The outer wall of their outer tube 22 is in close contact with the inner wall of the hot air duct 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com