Oxygen carrier for preparing synthesis gas by catalytic partial oxidation of methane

A technology for catalyzing partial oxidation and oxygen carrier, applied in catalyst activation/preparation, physical/chemical process catalyst, inorganic chemistry, etc., can solve the problems of unrealistic, high cost, high price, etc., achieve simple molding, strong adaptability, No secondary pollution effect

Inactive Publication Date: 2011-06-15

KUNMING UNIV OF SCI & TECH

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Through experimental research, the applicant of this patent has previously determined a composite oxygen carrier for the catalytic partial oxidation of methane to synthesis gas. A certain ratio of cerium, iron and zirconium metal composite oxides has excellent performance and excellent performance in the catalytic partial oxidation of methane. Good thermal stability, but simply using it as a catalyst is expensive and costly, and it is unrealistic in scaled-up industrial production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

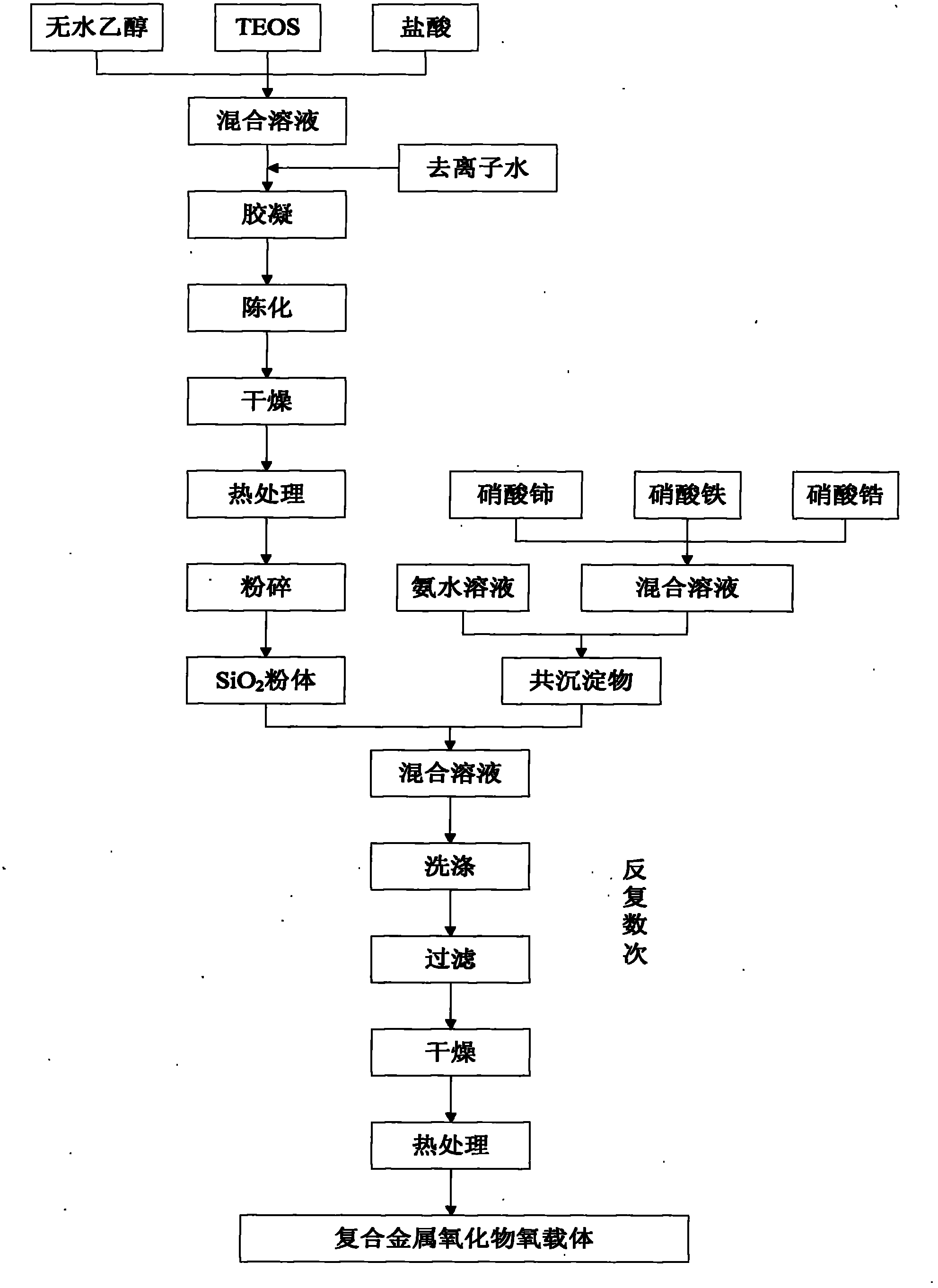

Login to View More Abstract

The invention discloses a cerium-iron-zirconium based composite oxygen carrier material with Al2O3, MgO and SiO2 as carriers, which is used for transmission of partial oxygen in a partial oxidation process. In the invention, three common cheap oxides are used as carriers, cerium-iron-zirconium of certain proportion and the carriers are mixed with a coprecipitation method or a sol-gel method so as to prepare the cerium-iron-zirconium based composite metallic oxide carrier with different carriers. The carrier is beneficial to improvement of oxygen storage capacity and cycle performance of the oxygen carrier, can improve the combustion efficiency of fuels at the same time of obviously reducing the cost, achieves the purpose of modification, and is easy to use in amplified production, wherein MgO is an alkaline oxide, Al2O3 is a neutral oxide and SiO2 is an acidic oxide.

Description

Oxygen carrier for catalytic partial oxidation of methane to synthesis gas technical field The invention relates to an oxygen carrier used for catalytic partial oxidation of methane to produce synthesis gas, which belongs to the field of energy efficient utilization. Background technique Direct partial oxidation of methane to synthesis gas by using lattice oxygen in solid oxygen carrier is a new method emerging in the field of natural gas application in recent years. The reaction is a gas-solid reaction. The whole process can be divided into two processes, which can be carried out in two connected reactors respectively. The first process takes place in the first reactor, called the partial oxidation chamber, in which lattice oxygen in solid oxygen carriers partially oxidizes methane to produce carbon monoxide and hydrogen, while oxygen carriers in higher valence states are reduced into a low-priced state. The second process is the oxygen carrier regeneration process, whi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B3/40B01J23/83B01J23/06B01J37/03

CPCY02P20/52

Inventor 王华程显名魏永刚李孔斋祝星胡建杭

Owner KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com