Power generation system with partial oxygen-enriched combustion combined with calcium-based chain and CO2 capturing method

A power generation system, oxygen-enriched combustion technology, applied in the combustion method, separation method, combustion air/fuel supply, etc., can solve the problems of concentration drop, lower capture rate, etc., to achieve CO2 concentration increase, increase power generation, reduce requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

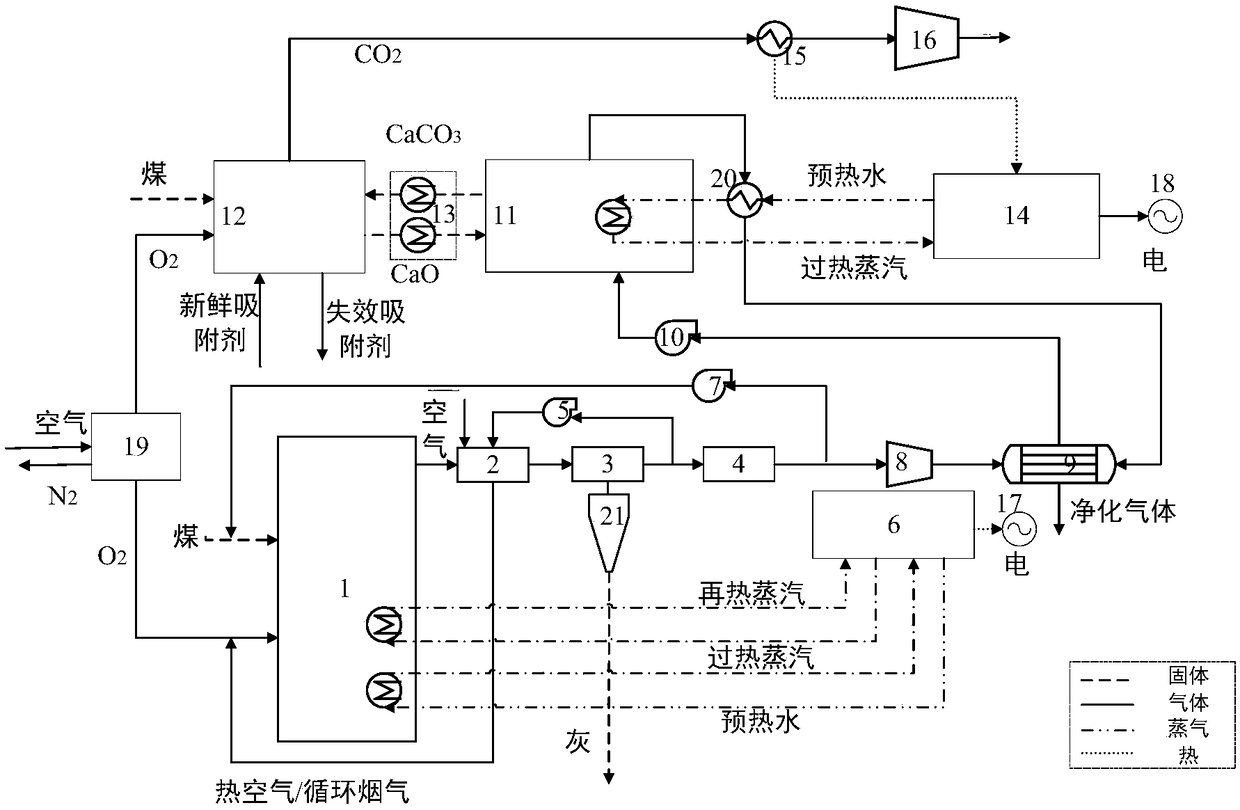

[0030] A coal-fired power generation system with partial oxygen-enriched combustion combined with calcium-based chemical chains and CO 2 The capture method is a partial oxygen-enrichment method using a mixture of air, oxygen and recirculated flue gas as a combustion aid, so that the boiler outlet flue gas CO 2 The gas concentration is increased to 30% to 60%, and the flue gas enters the calcium-based chemical chain combustion post-combustion capture device, and then deeply removes CO 2 .

[0031]The partial oxygen-enriched combustion coal-fired power generation system combined with calcium-based chemical loop mainly includes flue gas circulation partial oxygen-enriched coal-fired boiler, flue gas dust removal and desulfurization device, main steam power generation system, post-combustion capture device based on calcium-based chemical looping, Secondary steam power generation system, CO 2 Cools compression units and air separators.

[0032] Boiler outlet flue gas CO 2 The r...

Embodiment 2

[0042] Such as figure 1 as shown, figure 1 is a schematic diagram of a coal-fired power generation system with partial oxyfuel combustion combined with a calcium-based chemical chain. Such as figure 1 As shown, it uses a mixture of air, oxygen and recycled flue gas as a combustion aid, in which the mass flow rate of oxygen is 96.4kg / s, the volume of circulating flue gas is 616kg / s, and the proportion of flue gas circulation is 72%. The mass flow rate of air is 100.2kg / s, so that the boiler outlet flue gas CO 2 The gas concentration is increased to 45%, and the flue gas enters the calcium-based chemical loop post-combustion capture device for deep removal, CO 2 The capture efficiency increased to 97.6%.

[0043] The partial oxygen-enriched combustion coal-fired power generation system combined with calcium-based chemical loop mainly includes flue gas circulation partial oxygen-enriched coal-fired boiler, flue gas dust removal and desulfurization device, main steam power gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com