Method and device for improving heat efficiency of combustion furnace by oxygen-rich partial oxygen-enriched jet flow combustion supporting

A technology of a fuel injection device and a combustion furnace, which is applied in the field of comprehensive energy saving and emission reduction, can solve the problems of reducing the air intake, limited temperature measurement points, unscientific and other problems, and achieves the effects of reducing the combustion air volume, increasing the temperature, and improving the heat radiation of the flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

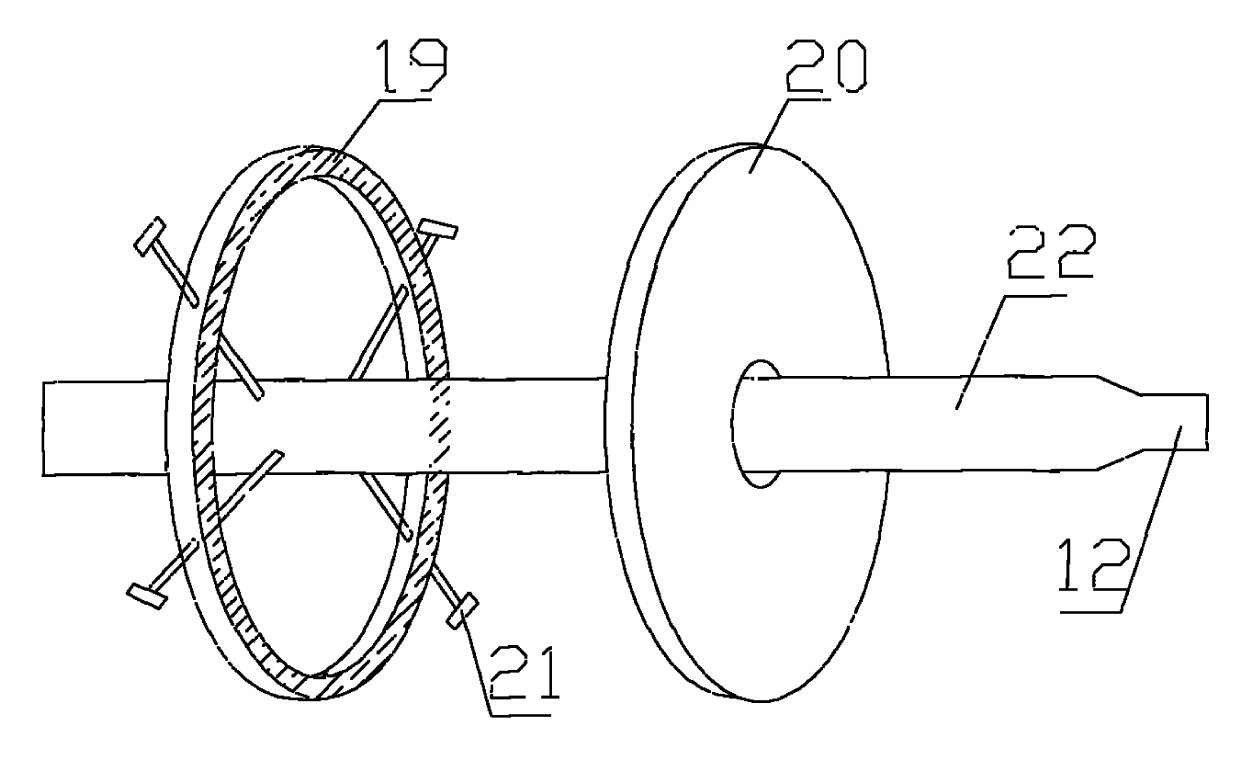

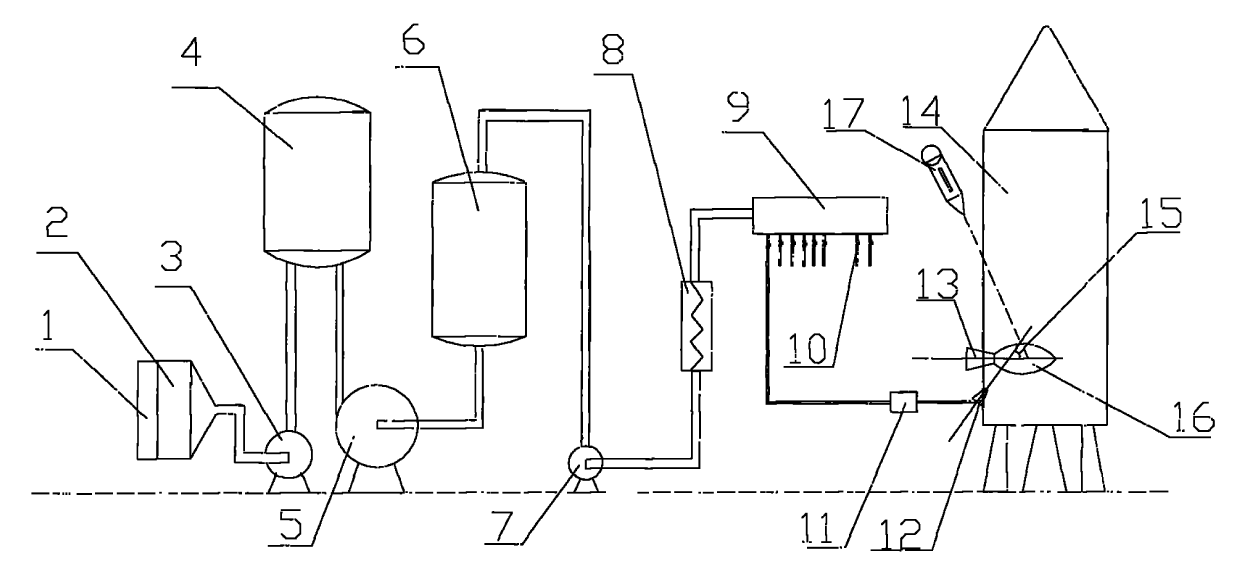

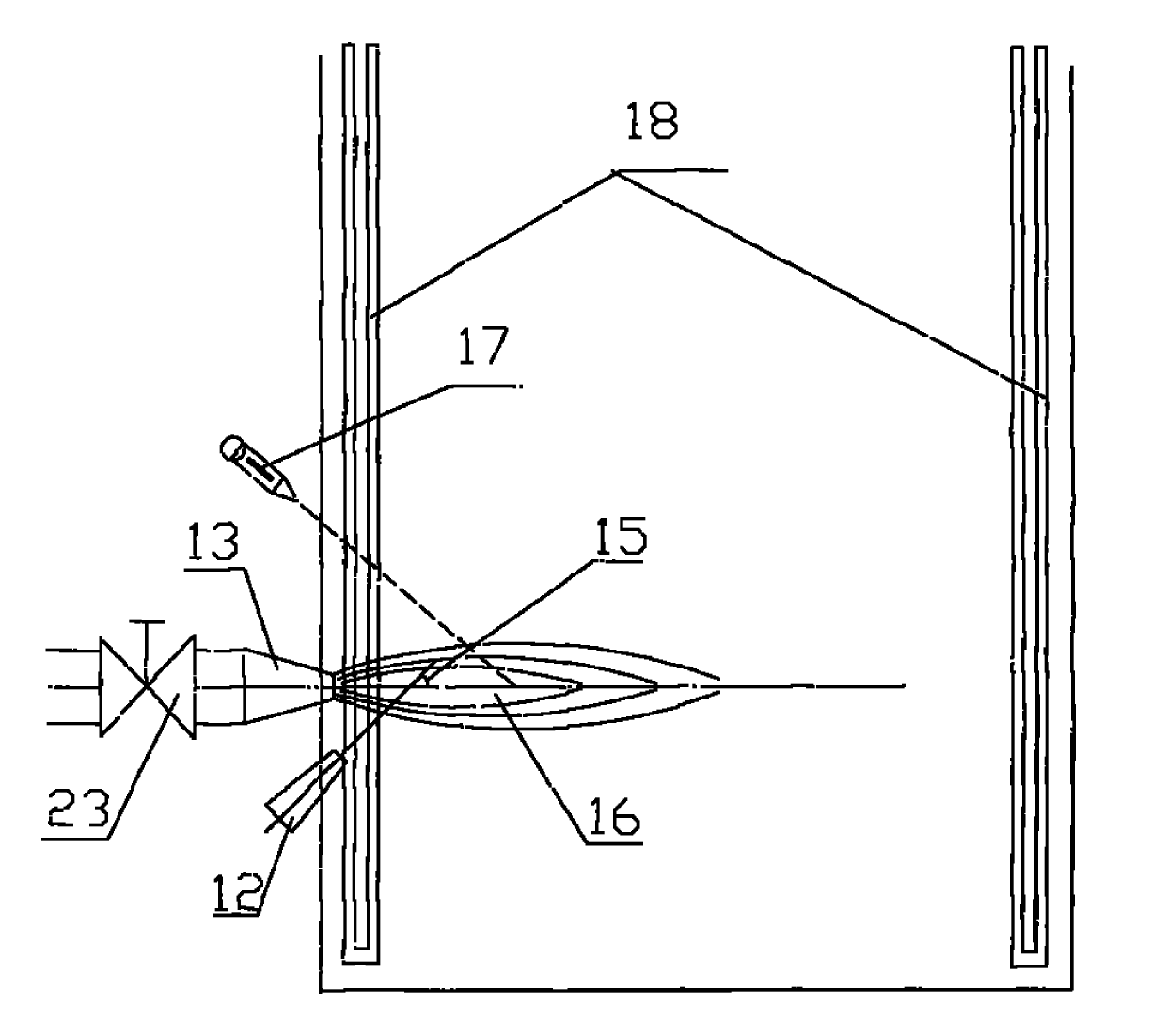

[0030] exist Figure 1-3In the shown embodiment: the filter cotton 1 is fixed on the inlet of the high efficiency air filter 2, the air supply device 3 is connected between the outlet of the high efficiency air filter 2 and the oxygen-enriched membrane device 4, and the outlet of the oxygen-enriched membrane device 4 is sequentially Connect the gas booster 7 through the vacuum pump 5 and the gas-water separation device 6, the gas booster 7 is a booster pump, the outlet of the gas booster 7 is connected to the inlet of the oxygen-enriched preheater 8, and the outlet of the oxygen-enriched preheater 8 The outlet is connected to the oxygen-enriched gas distributor 9, and each outlet pipeline of the oxygen-enriched gas distributor 9 is equipped with a regulating valve 10, and each regulating valve 10 is connected to a nozzle fine-tuning device 11 and a corresponding oxygen-enriched nozzle 12, a combustion furnace 14 Two oxygen-enriched nozzles 12 are arranged symmetrically on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com