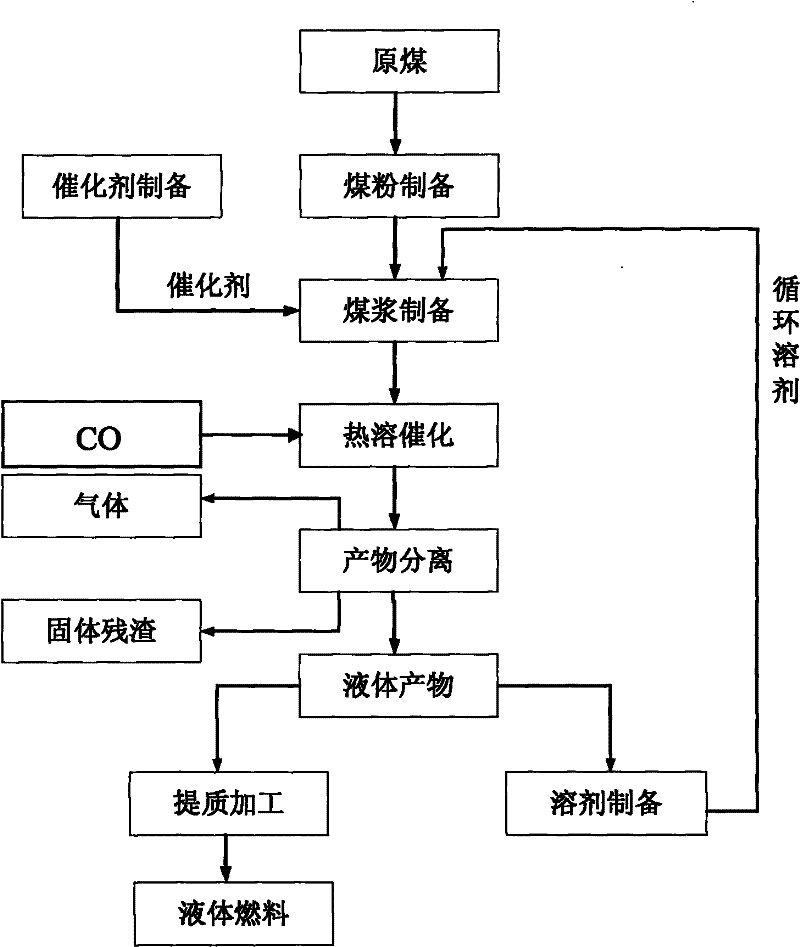

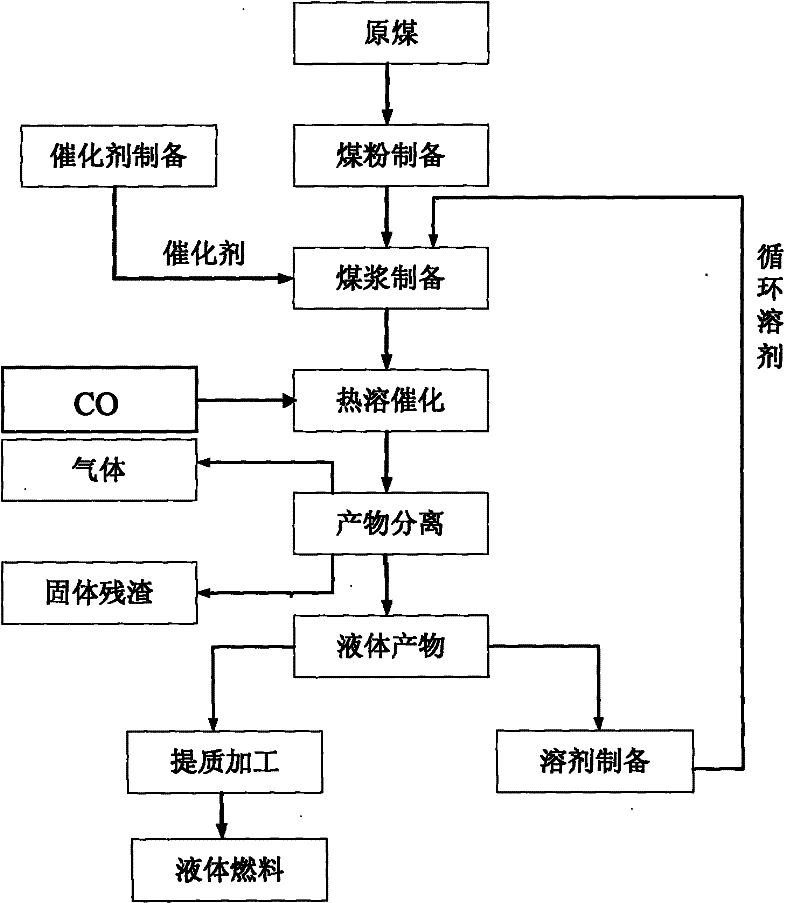

Lignite solubilizing and catalytic liquefaction method in non-hydrogen atmosphere

A catalytic liquefaction and atmosphere technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of increasing energy consumption and investment of coal drying equipment, high production costs, high energy consumption, etc., to reduce water pollution, cost Low, reduce the effect of water production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Lignite coal powder with a water content of about 15%, solvent (coal agent ratio: 1:2) and catalyst are fully stirred and mixed to form a coal slurry, FeS 2 The amount of catalyst added is 1% relative to the mass of pulverized coal. Feed pure CO gas, and the feed rate of CO gas is 25 cubic meters / Kg coal slurry. Under the condition of reaction temperature of 430°C, pressure of 8.0MPa, and reaction time of 30 minutes, the coal slurry was solubilized and catalyzed for liquefaction, and the yield of liquefied oil was 33.68%, and the yield of water was 9.11%. Compared with the result of the comparative example, the yield of liquefied oil is increased, and the yield of water is decreased.

Embodiment 2

[0031] Lignite coal powder with a water content of about 15%, solvent (coal agent ratio: 1:2) and catalyst are fully stirred and mixed to form a coal slurry, FeS 2 The amount of catalyst added is 1% relative to the mass of pulverized coal. Feed pure CO gas, and the feed rate of CO gas is 50 cubic meters / Kg coal slurry. Under the conditions of a reaction temperature of 430° C., a pressure of 8.0 MPa, and a reaction time of 30 minutes, the yield of liquefied oil was 35.27%, and the yield of water was 7.96%. Compared with the result of Example 1, the yield of liquefied oil is further improved, and the yield of water is greatly reduced. This shows that CO improves the effect of coal liquefaction to a certain extent and reduces the problem of water pollution.

Embodiment 3

[0033] Lignite coal powder with a water content of about 15%, solvent (coal agent ratio: 1:2) and catalyst are fully stirred and mixed to form a coal slurry, FeS 2 The amount of catalyst added is 1% relative to the mass of pulverized coal. Feed pure CO gas, and the feed rate of CO gas is 500 cubic meters / Kg coal slurry. Under the conditions of a reaction temperature of 430° C., a pressure of 8.0 MPa, and a reaction time of 30 minutes, the yield of liquefied oil was 37.46%, and the yield of water was 6.15%. Compared with the result of Example 2, the yield of liquefied oil is improved, but the increase is limited. This shows that the amount of CO added has a maximum value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com