Safety valve for nucleus

A safety valve, nuclear technology, applied in the field of safety valve, can solve the problems of pressure medium, high temperature impact, easy damage, etc., to achieve the effect of light weight, high reliability and wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

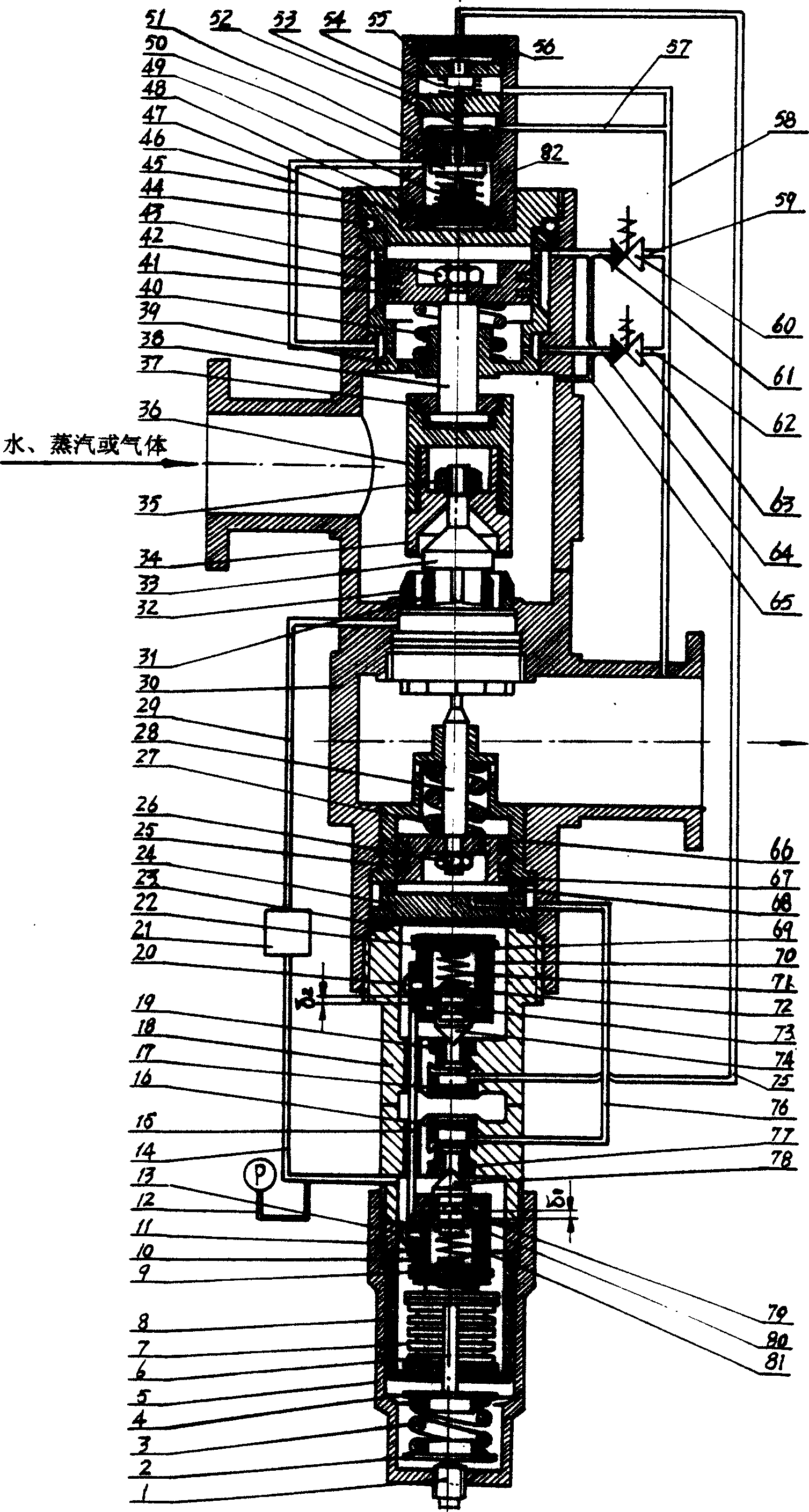

[0039] The novel nuclear safety valve provided by the invention is composed of an auxiliary valve, a main valve, a relay valve, and a forced opening and closing solenoid valve. The structure of the main valve is as figure 1 As shown, the main valve seat (31), (32) is screwed in the main valve body (30) from bottom to top in the form of threaded connection, and the annular space formed by the main valve seat (31), (32) and the pulse Pipe (29) is connected. The main valve disc (33) is covered on the main valve seat (31), and the main valve rod (28) fixedly connected with the main valve disc (33) has a threaded part at the lower end to pass through the piston (67). Nut (26) is affixed on the piston (67) with main valve stem (28). The compression force of the pre-tightening spring (27) acting on the piston (67) acts on the main valve disc (33) through the main valve rod (28), so that part of it becomes the pre-tightening sealing force of the main valve disc (33). . The other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com