Phase-change energy storage microcapsules and preparation method thereof

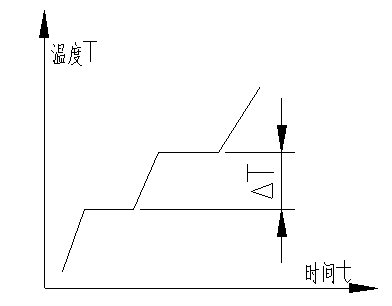

A technology of phase-change energy storage and microcapsules, which is applied in the field of phase-change energy storage, can solve the problems of poor stability, easy failure of phase-change energy storage microcapsules, and short service life, and achieve good stability, thermal shock buffer, and The effect of improving the service life of the cooling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

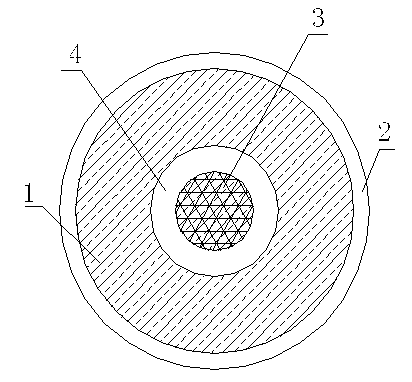

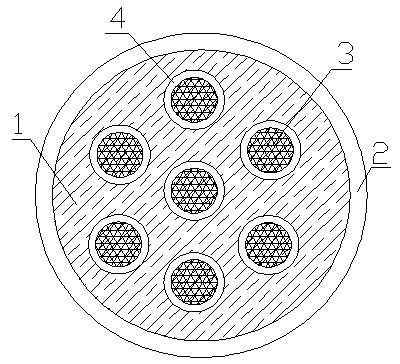

[0036] (1) Preparation of sub-microcapsules

[0037] Mix and emulsify the second phase change material, the prepolymer solution of the second wall capsule, and the emulsifier to form an emulsion; then place the emulsion in a constant temperature water bath, perform demulsification and filtration after the reaction is complete, and obtain a precipitate, and cleaning and drying the precipitate to obtain sub-microcapsules in which the second wall capsule wraps the second phase change material;

[0038] (2) Coating with the first phase change material

[0039]Dispersing the sub-microcapsules prepared in the above step (1) into the liquid first phase change material, stirring to form a uniform dispersion solution of sub-microcapsules;

[0040] (3) Preparation of the first wall capsule

[0041] Mix the uniform dispersion solution prepared in step (2), the prepolymer solution of the first wall capsule, and the emulsifier, and stir until uniformly mixed; then put the mixed solution ...

Embodiment 1

[0059] First, mix 10g of n-eicosane, 10g of styrene, and 0.1g of azobisisobutyronitrile at 45°C to form an oil phase; mix 0.1g of sodium dodecylbenzenesulfonate with 100g of water to form water box. Then the above oil phase and water phase are mixed and emulsified, the mechanical stirring speed is 350r / min, and the stirring time is 15min. , the water bath time is 8h. Cool naturally after the reaction is complete, then add saturated NaCl solution to the above cooling liquid, and filter until the solution has obvious flocculent precipitate or paste to obtain the precipitate. Then the precipitate was washed three times with distilled water and twice with absolute ethanol. After washing, vacuum-dry at 40° C. for 36 hours to obtain daughter microcapsules. It is determined that the average particle diameter of the sub-microcapsules is 100nm, and the average thickness of the second wall capsule is 20nm.

[0060] Melt 15g of n-heptadecane into a liquid, then disperse the obtained ...

Embodiment 2

[0062] First, 10 g of styrene, 10 g of n-nonadecane, 0.1 g of azobisisobutyronitrile, 0.1 g of sodium dodecylbenzenesulfonate, and 100 g of water were mixed and emulsified at 40°C to form an emulsion. Mechanical stirring and ultrasonic treatment were carried out during the emulsification process, the mechanical stirring speed was 350r / min, and the stirring time was 30min; the ultrasonic frequency was 28kHz, and the ultrasonic time was 1.5min. Then place the formed emulsion in a constant temperature water bath at 70°C, and the reaction time is 8 hours; after the reaction is complete, it is naturally cooled; then add saturated NaCl solution to the above cooling solution until the solution appears obvious flocculent precipitate or paste Filtration was carried out to obtain a precipitate; then the obtained precipitate was washed; wherein the distilled water was washed 3 times, and the anhydrous ethanol was washed 2 times. After washing, vacuum drying was carried out at 40° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com