Circuit board element and welding flux separating and recovery method and device thereof

A technology for separation and recovery of circuit boards, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as volatilization or oxidation of circuit boards, large consumption of hot air, damage to the shape of components, etc., to achieve complete separation of solder, The effect of low energy consumption and small thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

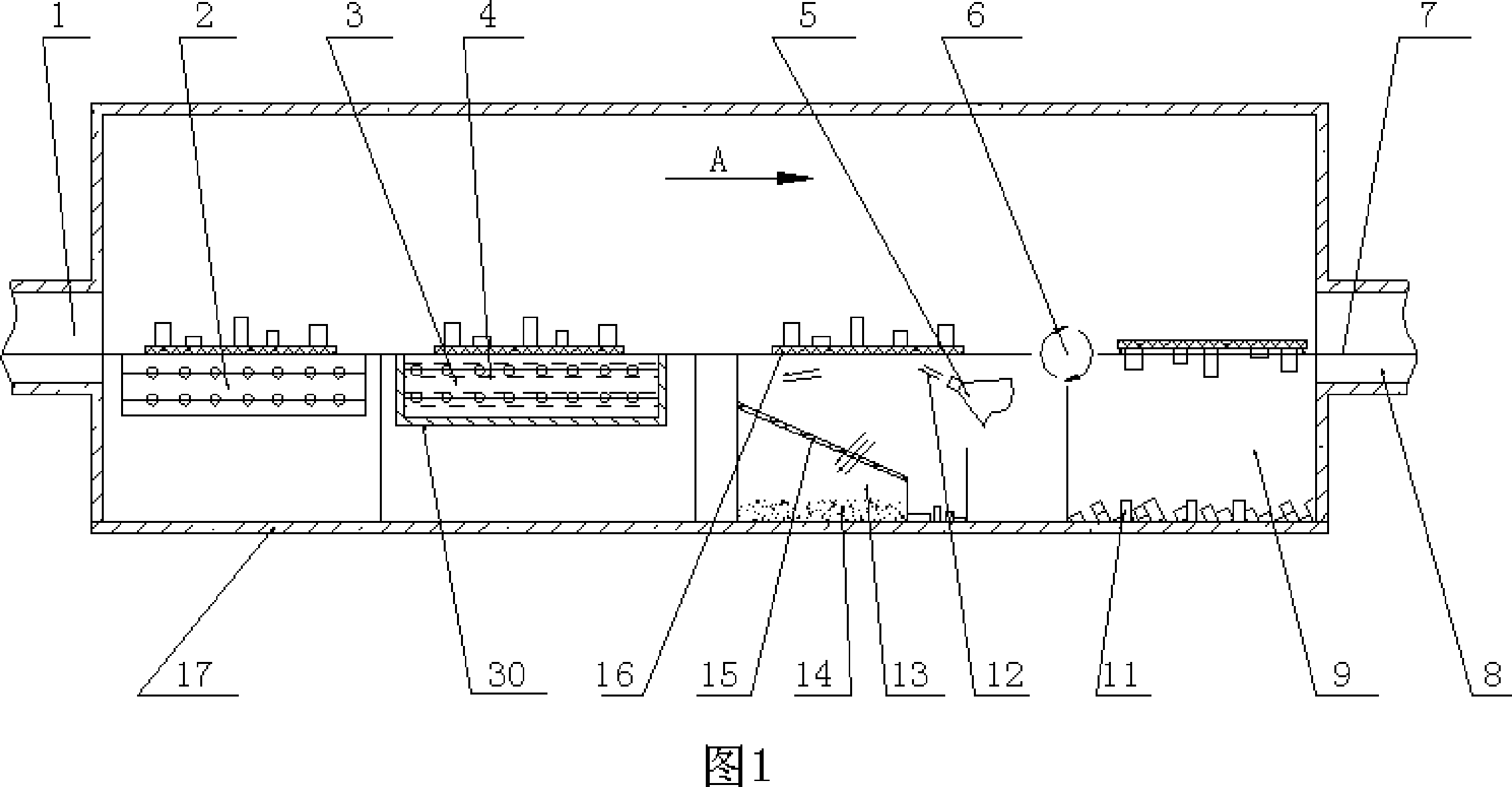

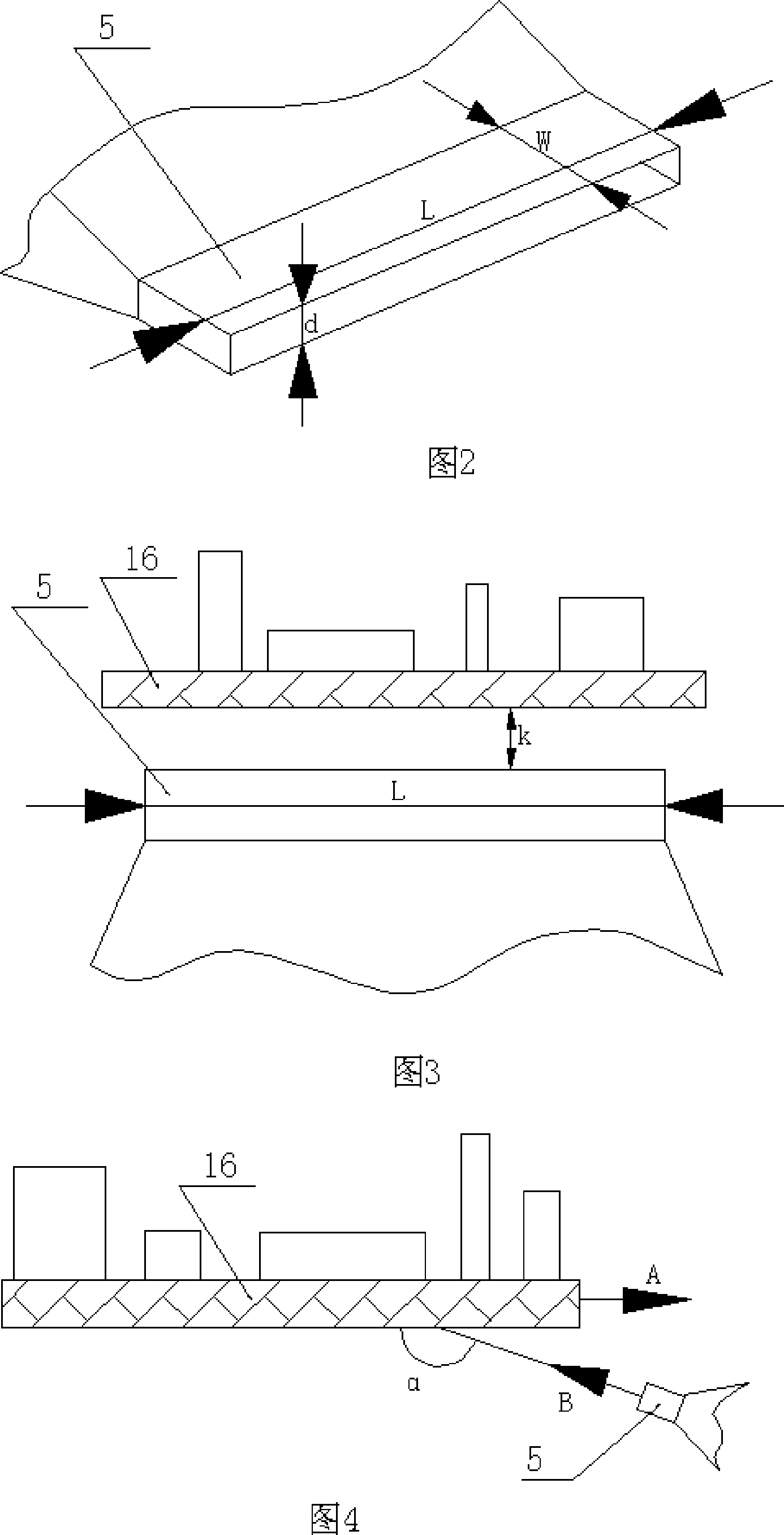

[0055] Referring to Fig. 1, after the circuit board 16 to be disassembled is clamped and fixed, it is transported to the preheating device 2 by the clamping and conveying mechanism 7 through the entrance 1 of the heat preservation chamber, and the whole is heated by the combination of the resistance wire or the infrared heating plate in the preheating device 2 and the hot air. The circuit board is preheated to 140-180°C.

[0056] The preheated circuit board 16 is sent to the heating device 3 to heat the circuit board 16 . The heating device 3 is composed of a solder melting tank 30 placed below the clamping and conveying mechanism 7. The molten solder 4 in the solder melting tank 30 is in contact with the soldering surface of the circuit board 16, and the soldering surface of the circuit board 16 is heated until the solder melts.

[0057] The heating method refers to the heating and welding process in the wave soldering process. The preheated circuit board 16 is passed throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com