Preparation method of flexible self-supporting silicon/graphene cathode material of lithium ion battery

A lithium-ion battery, graphene negative electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of limiting the commercial application of silicon-based negative electrodes, reducing electrochemical performance, and hindering ion transport and other issues to achieve the effect of avoiding rapid decline, avoiding capacity, and ensuring high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

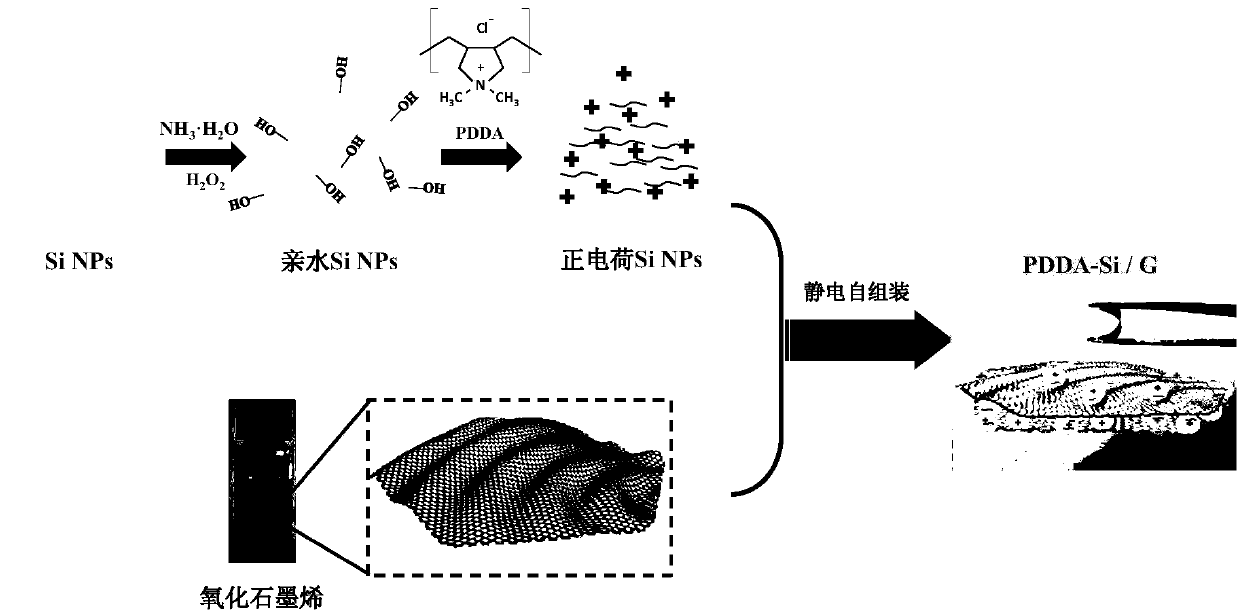

[0032] The preparation method of the present embodiment comprises the following steps:

[0033]Step 1. Disperse 200 mg of nano-silicon particles in 250 mL of boiling mixed solution and heat for 40 minutes, then wash with deionized water for 3 times and then centrifuge; the size of the nano-silicon particles is 50 nm to 100 nm; Aqueous ammonia with a concentration of 25%, hydrogen peroxide and water with a mass concentration of 20% are prepared according to a volume ratio of 1:1:5;

[0034] Step 2. Disperse the precipitate obtained by centrifugation in step 1 in a polydiene dimethyl ammonium chloride solution at room temperature for ultrasonic treatment for 1 hour, and then wash it with deionized water for 5 times. Vacuum drying to obtain positively charged nano-silicon particles;

[0035] Step 3, the positively charged nano-silicon particles obtained in step 2 are formulated into 20 mL of nano-silicon solution with a concentration of 1 mg / mL and ultrasonically treated, and th...

Embodiment 2

[0043] The preparation method of the present embodiment comprises the following steps:

[0044] Step 1. Disperse 200 mg of nano-silicon particles in 250 mL of boiling mixed solution and heat for 40 min, then wash with deionized water for 3 times and then centrifuge; the mixed solution is composed of 25% ammonia water and 20% Hydrogen peroxide and water are prepared according to the volume ratio of 1:1:4;

[0045] Step 2. Disperse the precipitate obtained by centrifugation in step 1 in a polydiene dimethyl ammonium chloride solution at room temperature for ultrasonic treatment for 1 hour, and then wash it with deionized water for 5 times. Vacuum drying to obtain positively charged nano-silicon particles;

[0046] Step 3, the positively charged nano-silicon particles obtained in step 2 are formulated into 20 mL of nano-silicon solution with a concentration of 1 mg / mL and ultrasonically treated, and then added dropwise to 10 mL of a graphene oxide solution with a concentration o...

Embodiment 3

[0050] The preparation method of the present embodiment comprises the following steps:

[0051] Step 1. Disperse 200 mg of nano-silicon particles in 250 mL of boiling mixed solution and heat for 40 min, then wash with deionized water for 3 times and then centrifuge; the mixed solution is composed of 25% ammonia water and 20% Hydrogen peroxide and water are prepared according to the volume ratio of 1:1:5;

[0052] Step 2. Disperse the precipitate obtained by centrifugation in step 1 in a polydiene dimethyl ammonium chloride solution at room temperature for ultrasonic treatment for 1 hour, and then wash it with deionized water for 5 times. Vacuum drying to obtain positively charged nano-silicon particles;

[0053] Step 3, the positively charged nano-silicon particles obtained in step 2 are formulated into 20 mL of nano-silicon solution with a concentration of 1 mg / mL and ultrasonically treated, and then added dropwise to 10 mL of a graphene oxide solution with a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com