Hydrogel fiber based on luminescent MOFs (Metal organic Frameworks), preparation method therefor and sensing device

A sensing device and hydrogel technology, which is applied in the field of optical fiber fluorescence sensing, can solve the problems of weak mechanical bonding between luminescent MOFs materials and optical fibers, difficulty in recycling for secondary use, and fragile fluorescent detection materials, so as to achieve distributed and multi-parameter real-time monitoring applications, enhanced mechanical integration, and improved sensor applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

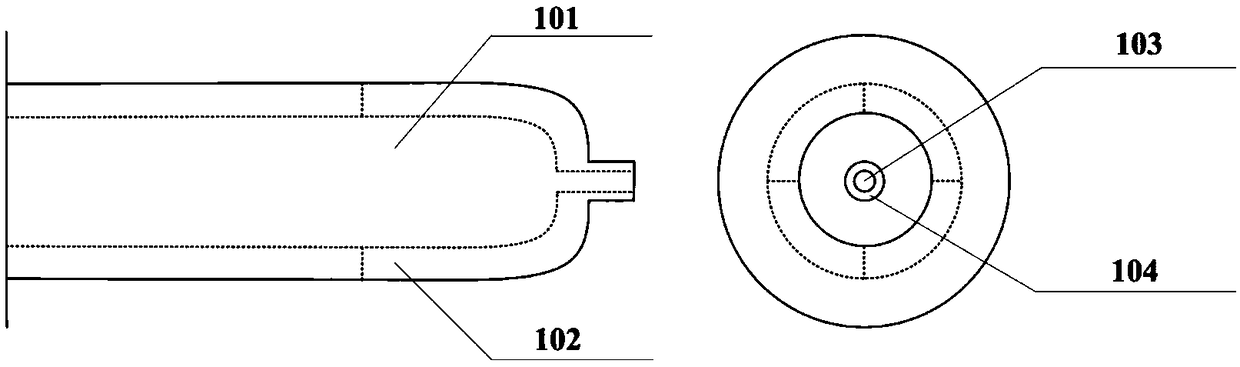

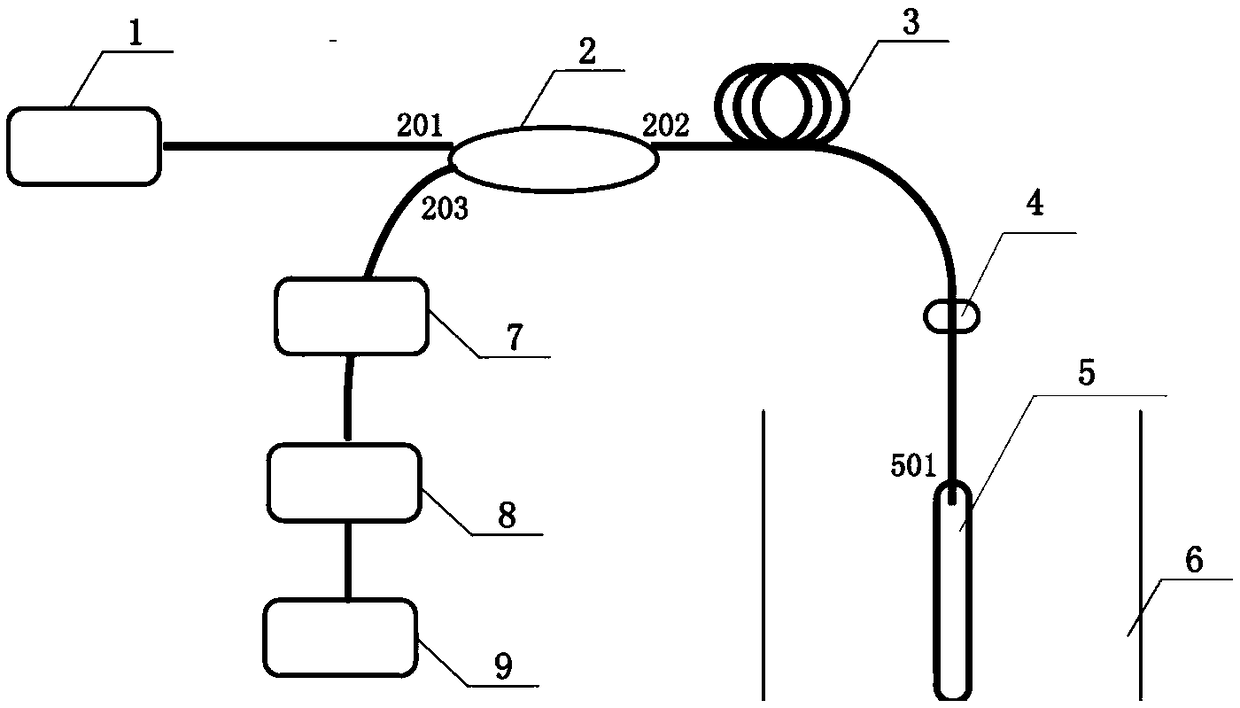

[0041] A method for fabricating a hydrogel optical fiber based on a luminescent metal-organic framework material.

[0042] Step 1: Preparation of europium-doped naphthalene dicarboxylic acid MOFs material with high hydrothermal stability: the chemical formula of europium-doped naphthalene dicarboxylate MOFs is

[0043] (CH 3 ) 2 NH 2 ] 2 [Eu 6 (m 3 -OH) 8 (1,4-NDC) 6 (H 2 O) 6 , where the mass fraction of Eu is 36%. The europium-doped naphthalene dicarboxylic acid MOFs were synthesized by a solvothermal method, specifically, 1,4-naphthalene dicarboxylic acid (9.41 mg, 0.0435 mmol), Eu(NO 3 ) 3 ·6H 2 O (19.4 mg, 0.0435 mmol), 2-fluorobenzoic acid (48.7 mg, 0.348 mmol) were dissolved in dimethylformamide (2.2 mL), H 2 O (0.5 mL), and HNO 3 (0.3 mL, the concentration is 3.5 mol / liter, the solvent is dimethylformamide), and then the glass bottle containing the mixed liquid is placed at 115 degrees Celsius for 60 hours.

[0044] The hydrogel precursor is mixed by po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com