Light flange plate hub and machining process thereof

A processing technology and lightweight technology, applied in the direction of flange connection, metal processing equipment, other manufacturing equipment/tools, etc., can solve the problems of multiple burrs, aggravated processing work, etc., and achieve reduced work intensity, clear light spots, and safe burr inspection simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

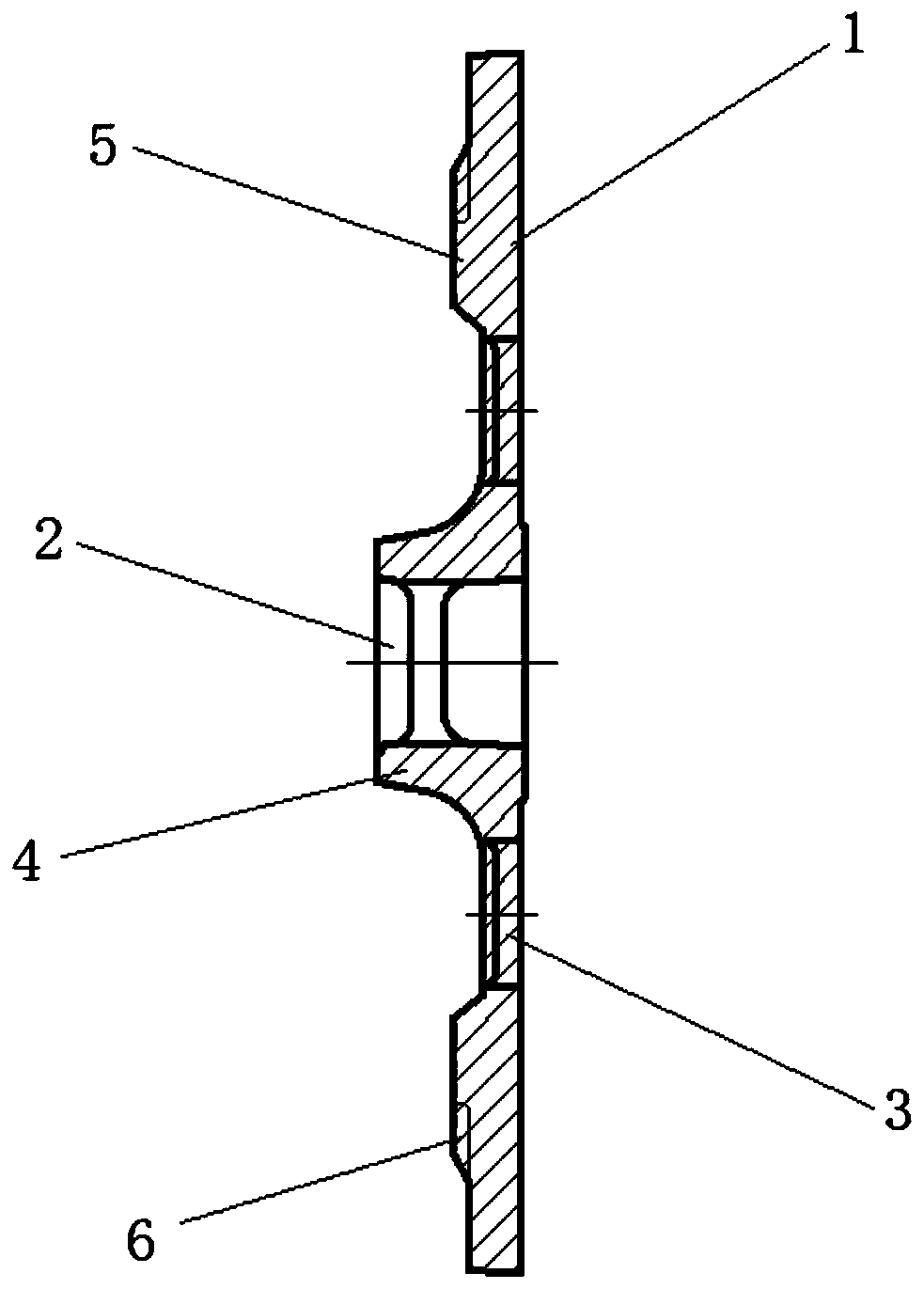

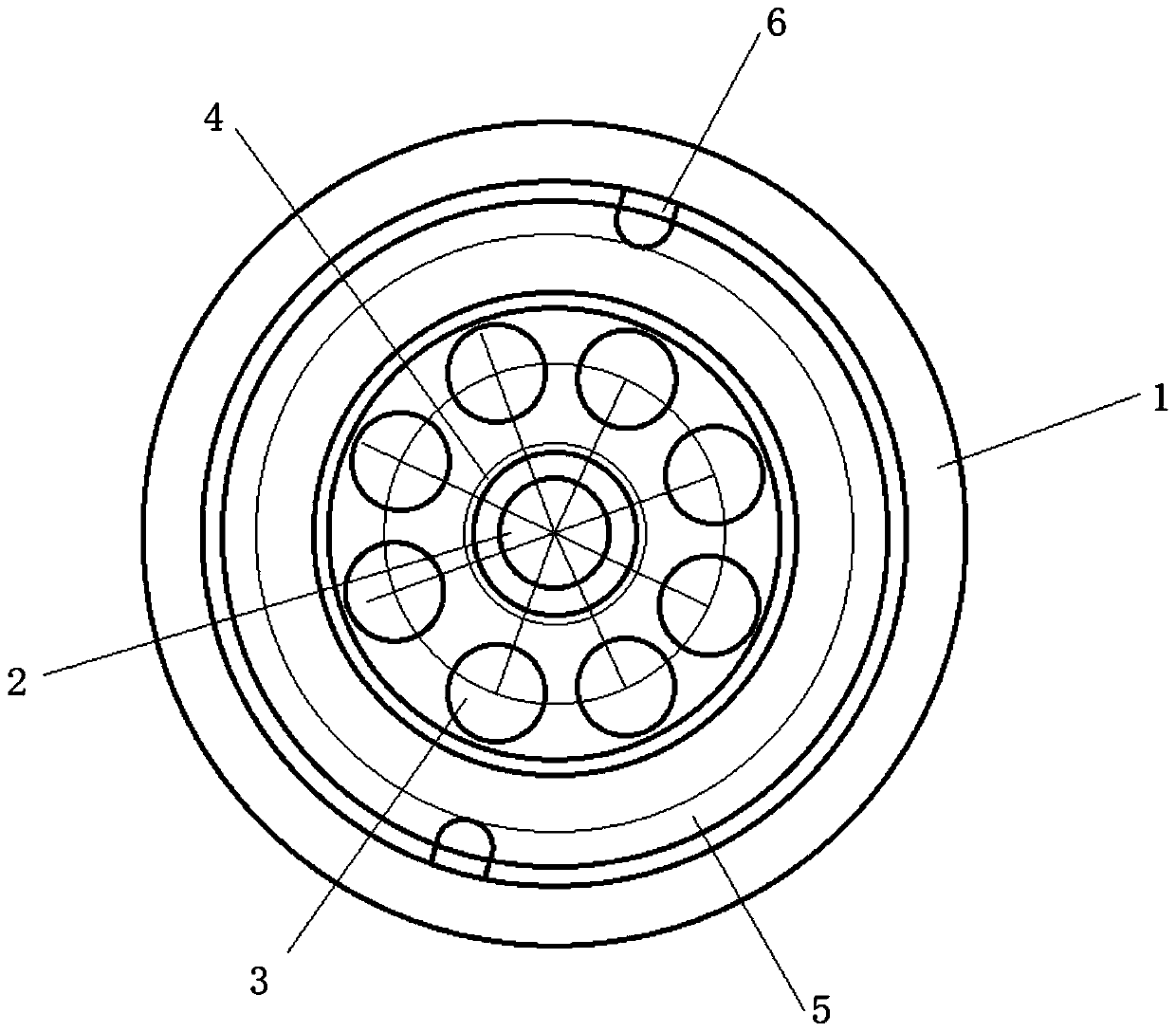

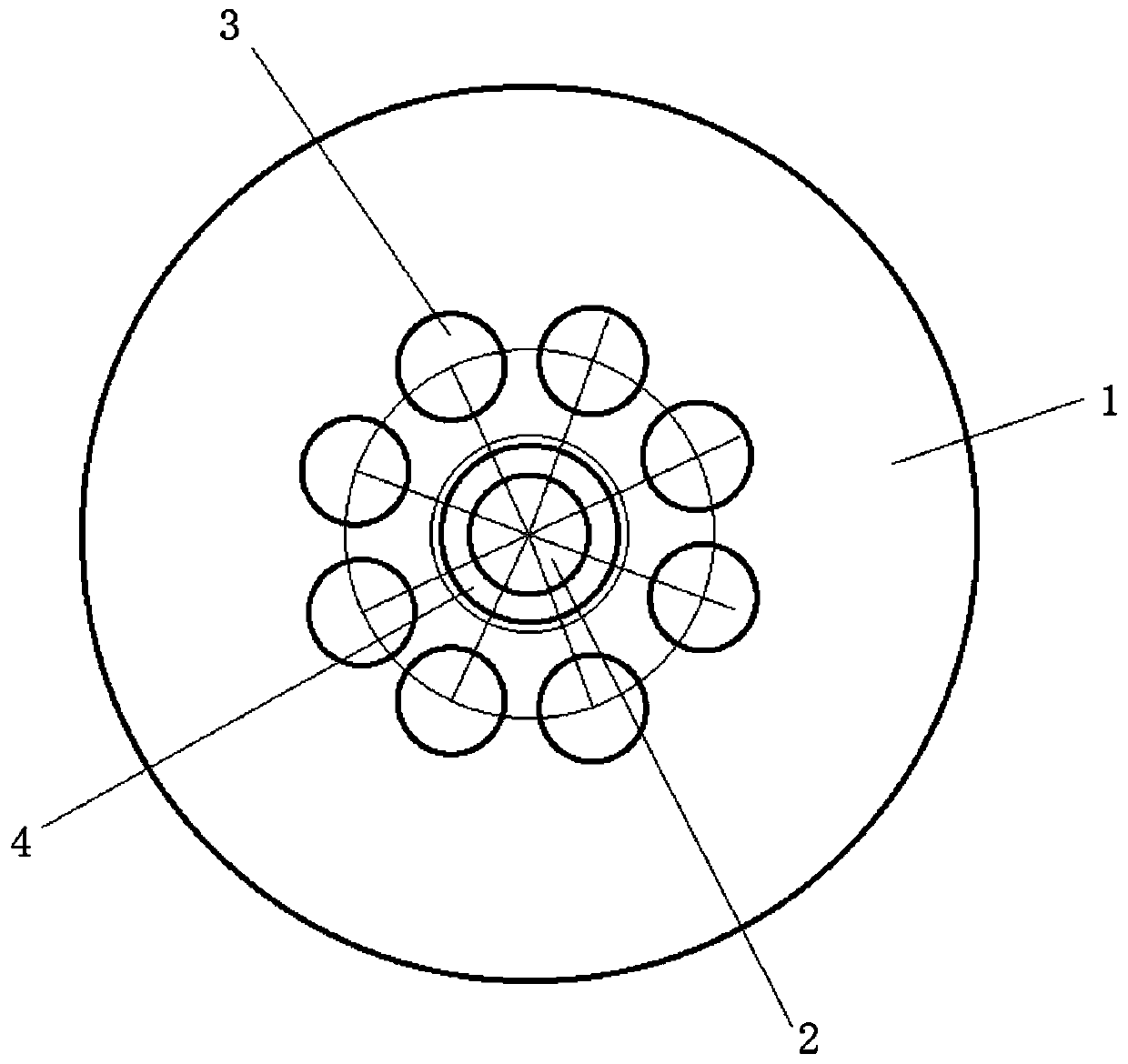

[0046] see figure 1 , figure 2 and image 3 , a lightweight flange hub, comprising a flange base 1, a central through hole 2 is dug in the center of the flange base 1, and an annular limiter matching the central through hole 2 is arranged at the center of the flange base 1 The position part 4 and the reinforcing protrusion 5, and the annular limiting part 4 and the reinforcing protrusion 5 are integrally formed with the flange base 1, the reinforcing protrusion 5 is located outside the annular limiting part 4, and the annular limiting part 4 and the reinforcing A plurality of outer holes 3 are drilled on the flange base 1 between the protrusions 5, and the plurality of outer holes 3 are arranged equidistantly around the central through hole 2, and a pair of U-shaped grooves 6 are dug on the reinforcing protrusions 5, and the center Both the through hole 2 and the outer hole 3 are punched by a punching auxiliary device, which can prevent deformation and largely avoid punchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com