Abrasion-resistant and ultraviolet-aging-resistant epoxy composite material and preparation method thereof

A wear-resistant, UV-resistant, and composite material technology, applied in the field of epoxy resin composite materials, can solve the problems of not having large-scale industrial production conditions, not being able to effectively improve the performance of epoxy resin, and not being able to combine two materials to achieve high efficiency. Stabilize UV absorbing ability, improve UV aging resistance, and effect of low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

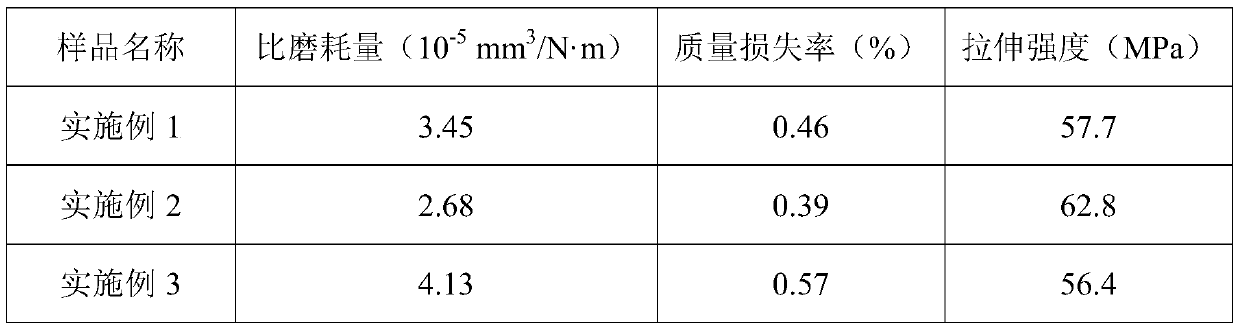

Examples

preparation example T

[0038] Preparation example TiO 2 / Ti 3 C 2 Preparation of nanocomposites

preparation example 1

[0040] 1) Add 1.25mmol of TBOT into 10mL ethanol solution, stir for 1h, and obtain TiO 2 Precursor solution; 2.5mmol of Ti 3 C 2 The powder was added to 30mL water and ethanol mixed solvent (the volume ratio of water and ethanol was 1:1), and ultrasonically dispersed for 0.5h to obtain Ti 3 C 2 Dispersion; TiO will be obtained 2 The precursor solution was slowly added dropwise to the Ti 3 C 2 In the dispersion liquid, stir vigorously at room temperature for 2 hours to obtain a uniform mixed solution;

[0041] 2) Transfer the mixed solution obtained in step 1) to a polytetrafluoroethylene liner, seal the autoclave, and react at 160° C. for 24 hours;

[0042] 3) After the reaction in step 2) is completed and cooled naturally, the powder obtained by the reaction is collected by centrifugation at 6000r / min, and then washed with deionized water and absolute ethanol respectively, and then the washed powder is placed in a vacuum drying oven at 60°C After drying for 12 hours, t...

preparation example 2

[0045] Other steps are identical with preparation example 1, and difference is that TBOT consumption is 2.5mmol in step 1), makes powdery TiO 2 / Ti 3 C 2 nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com