Preparation method of phenyl-polysilsesquioxane modified meta-aramid insulating paper

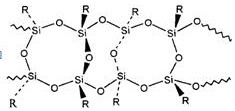

A technology of polysilsesquioxane and insulating paper, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of limited insulation life, poor mechanical properties and thermal stability, and achieve dielectric Reduced constant, improved shielding and cushioning effects, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

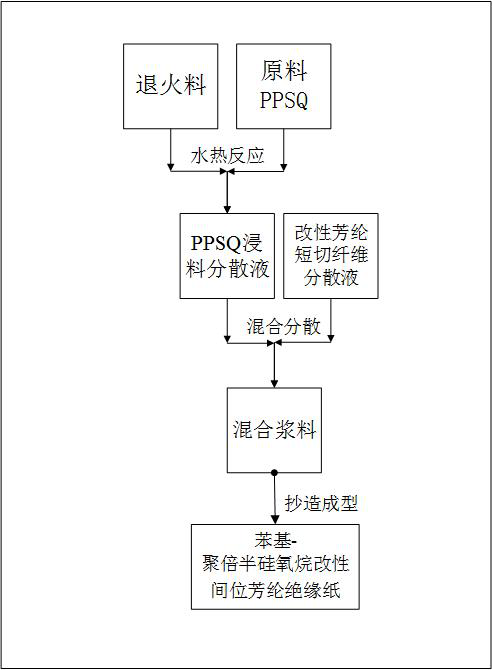

Method used

Image

Examples

example 1

[0038] In parts by weight, take 50 parts of sepiolite, 8 parts of aluminate coupling agent, and 100 parts of absolute ethanol in sequence, pour them into a ball milling tank, and add zirconia ball milling beads according to the mass ratio of balls to materials at 30:1 , after ball milling and mixing for 6 hours, the material was discharged to obtain a ball mill, and then the obtained ball mill was transferred to a vacuum drying oven, and the temperature was 95° C., and the pressure was 80Pa. Foam: In parts by weight, 80 parts of silicate, 30 parts of aluminum alkoxide, 200 parts of absolute ethanol, 40 parts of oleic acid, and 10 parts of modified sepiolite are mixed and poured into a three-necked flask. And transfer the three-necked flask into an ultrasonic disperser, and ultrasonically disperse for 60 minutes under the condition of an ultrasonic frequency of 55 kHz, then move the three-necked flask to a digital display speed measuring constant temperature magnetic stirrer, an...

example 2

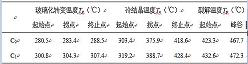

[0040] Add aramid chopped fiber and water into the reaction kettle at a mass ratio of 1:8, stir and disperse with a stirrer at a speed of 600r / min for 30 minutes, then add dopamine with 3% mass of aramid chopped fiber, and add dopamine solution lye with a mass of 10%; after continuing to stir and react for 2 hours, drop a silane coupling agent ethanol solution with a mass of 15% aramid chopped fibers into the reactor at a rate of 10mL / min, and wait until the silane coupling agent ethanol solution is added dropwise , continue to stir and react for 5 hours to obtain a modified aramid chopped fiber dispersion; then use a paper sample machine to copy the mixed slurry into shape, and heat press to obtain a dry paper sheet, and then use a calender to calender. That is to obtain the modified insulating paper hand-sheet, which is denoted as C0; the aramid chopped fiber is 6mm in length and 15um in diameter; the ethanol solution of the silane coupling agent is made of silane coupling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com