Forming method of composite material tie rod and composite material tie rod

A composite material and molding method technology, which is used in the forming of composite material tie rods and the field of composite material tie rods, can solve the problems of failure of connecting parts and easy damage to composite material structures, and achieves improved bearing capacity, high strength, and enhanced mechanical bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for forming a composite tie rod provided in this embodiment includes the following steps:

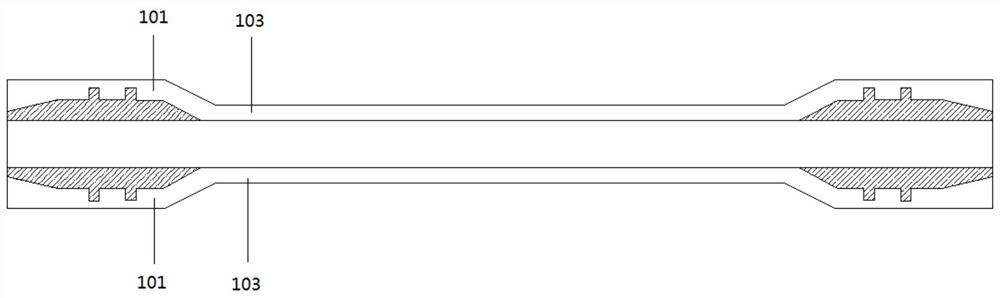

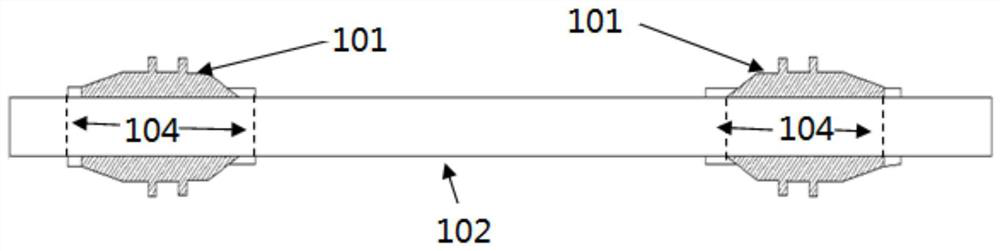

[0055] Step A, preparation of winding mold 102 and positioning of metal joint 101;

[0056] Specifically, in this step, the winding mold 102 is a round tube with an outer diameter of 54 mm and a length of 2 mm, with clamping ends at both ends, which can be clamped by a CNC winding machine. The inner diameter of the metal joint 101 is designed and prepared according to the outer diameter of the winding mold 102. The length of the metal joint 101 is 100mm, with two grooves with a depth of 2mm, and a score line 104 is designed on the outer surface of the winding mold 102 in the circumferential direction. The length is 1200mm, used to mark the position of the metal joint 101, such as image 3 shown. After marking the position of the metal joint 101, use carbon fiber yarn-12K to wrap the two ends of the metal joint 101 in a hoop direction (such as image 3 As shown), the p...

Embodiment 2

[0068] The forming method of the composite tie rod provided in this embodiment comprises the following steps:

[0069] Step A, winding molding mold preparation and metal joint positioning;

[0070] The outer diameter of the winding forming mold is 88mm, and the length is 2m. The inner diameter of the metal joint is designed according to the outer diameter of the winding forming mold to be 88mm, the outer diameter is 95mm, and the length is 100mm. Winding mold transitions such as Figure 4 As shown, there are engraved lines on the outer surface of the winding mold in the circumferential direction, which are used to mark the position of the metal joints, and the length of the engraved line is 1.5m;

[0071] Step B, wet winding;

[0072] Japan's Toray T700-12K carbon fiber is impregnated with resin. The resin material is TDE-85 / amine curing agent resin system, and then it is wound and formed on the winding molding mold with the metal joint 101 fixed by four-axis winding equipme...

Embodiment 3

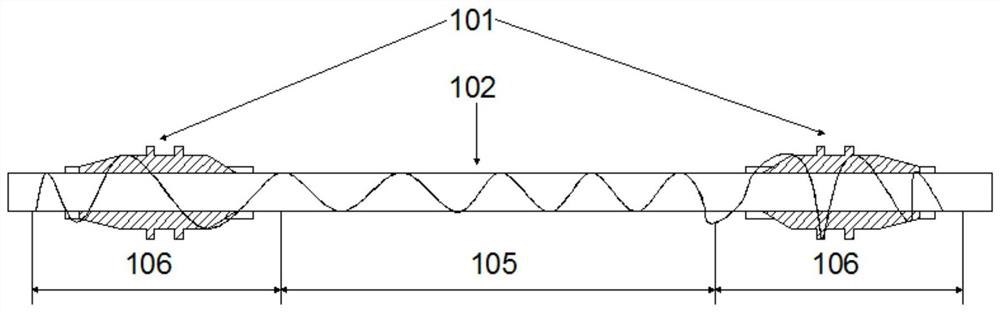

[0078] The composite pull rod provided in this embodiment includes a metal joint 101, the position where the two ends of the metal joint 101 are provided with a score line 104 and the position in the middle of the two ends of the metal joint are wrapped with dry fiber yarn, and the metal joint After winding 101 and dry fiber yarn, the resin infusion process is used to infuse resin. The main structure diagram is as follows: Figure 5 As shown, the outer diameter of the winding mold 102 is 65mm, and the length is 4.7m;

[0079] Metal joint 101, dry fiber yarn, and resin material are solidified integrally formed structures;

[0080] Preferably, the metal joint 101 has three concave-convex structures, and the length of the metal joint is 120 mm;

[0081] Specifically, the two ends of the metal joint 101 are inclined surfaces inclined at 30° to its axis, and the outer diameter of one end of the metal joint is 80 mm, and the outer diameter of the other end is 75 mm, and the overall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com