Multifunctional surface enhanced Raman substrate material, and preparation method and application thereof

A surface-enhanced Raman and substrate material technology, applied in Raman scattering, material analysis, material excitation analysis, etc., can solve the problems of Au nanoparticle loss, non-reusable, weak stability, etc., and achieve good signal consistency , easy operation, and the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

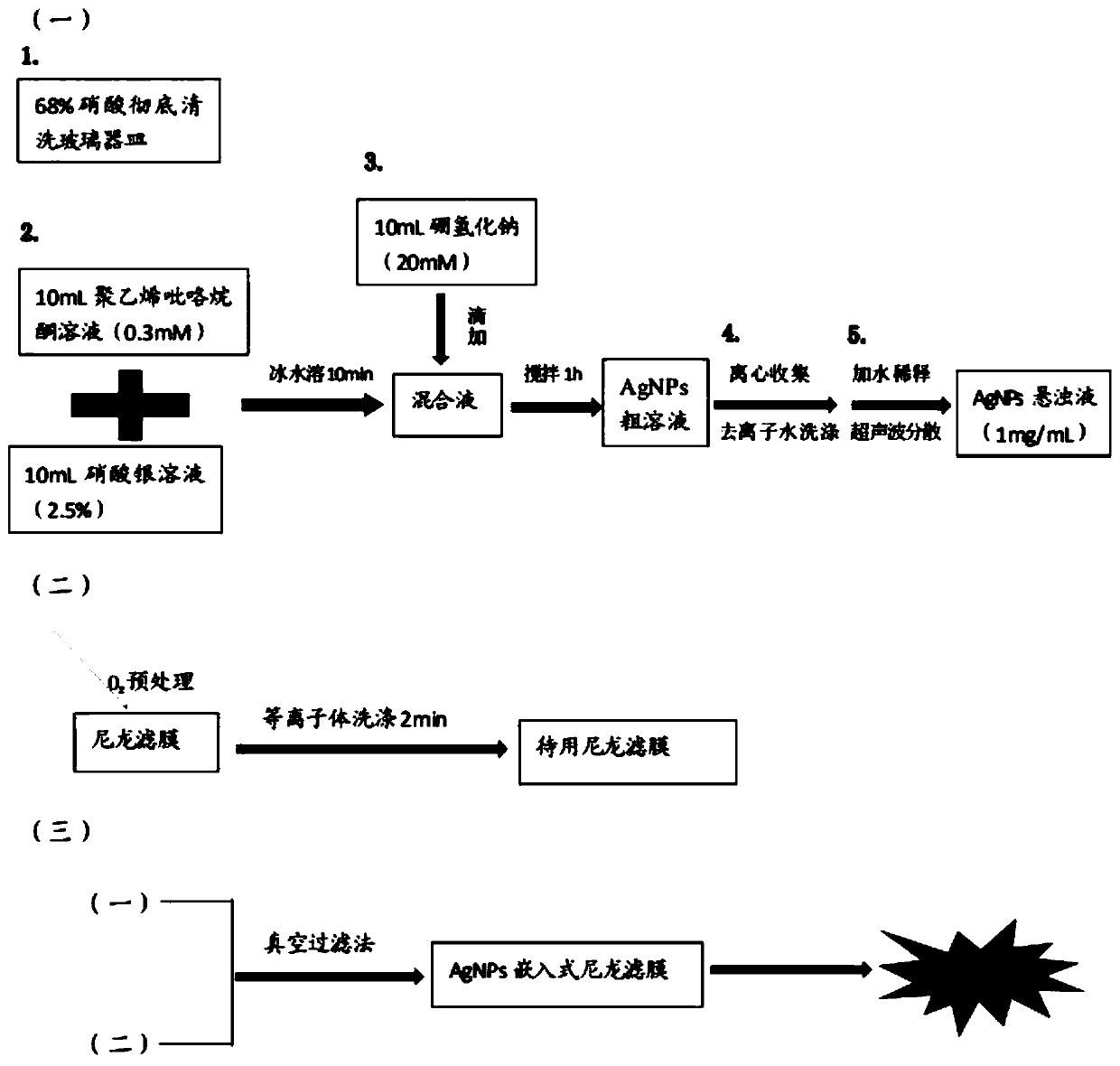

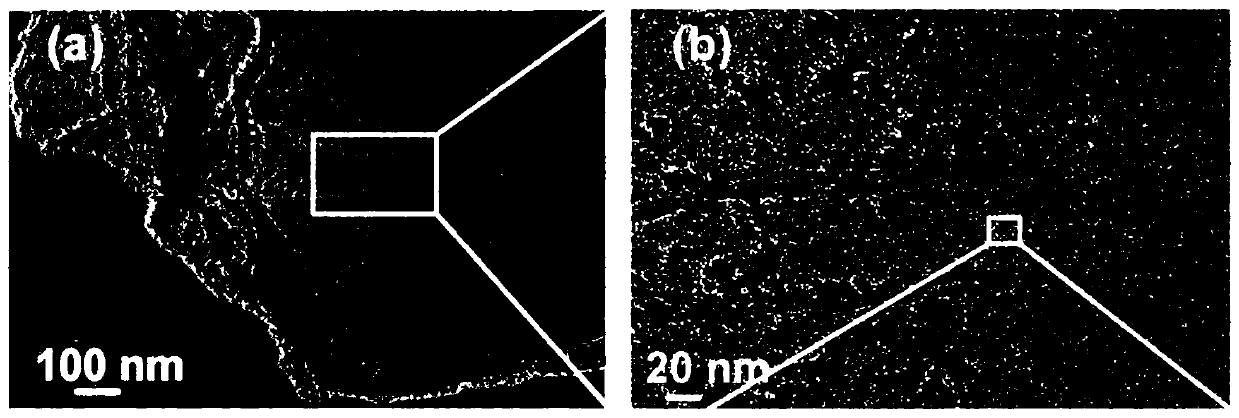

[0043] (1) Preparation of AgNPs suspension:

[0044] 1. Thoroughly clean glassware with 68% nitric acid;

[0045] 2. Then add 10mL 0.3mM polyvinylpyrrolidone (PVP, Mw~8000) solution and 10mL 2.5% silver nitrate solution into the beaker, and keep it in the ice-water bath for 10 minutes;

[0046] 3. Then 10 mL of 20 mM sodium borohydride was added dropwise to the mixture and stirred for 1 hour to form a crude solution of AgNPs;

[0047] 4. The formed AgNPs were collected by centrifugation and washed with deionized water (DI);

[0048] 5. Then disperse the AgNPs in the aqueous solution to prepare a 1 mg / mL AgNPs suspension, and thoroughly disperse the nanoparticles by ultrasonic waves for 30 minutes;

[0049] (2) Nylon filter membrane pretreatment: pretreatment with oxygen, then with plasma cleaning for 2 minutes to remove surface impurity molecules;

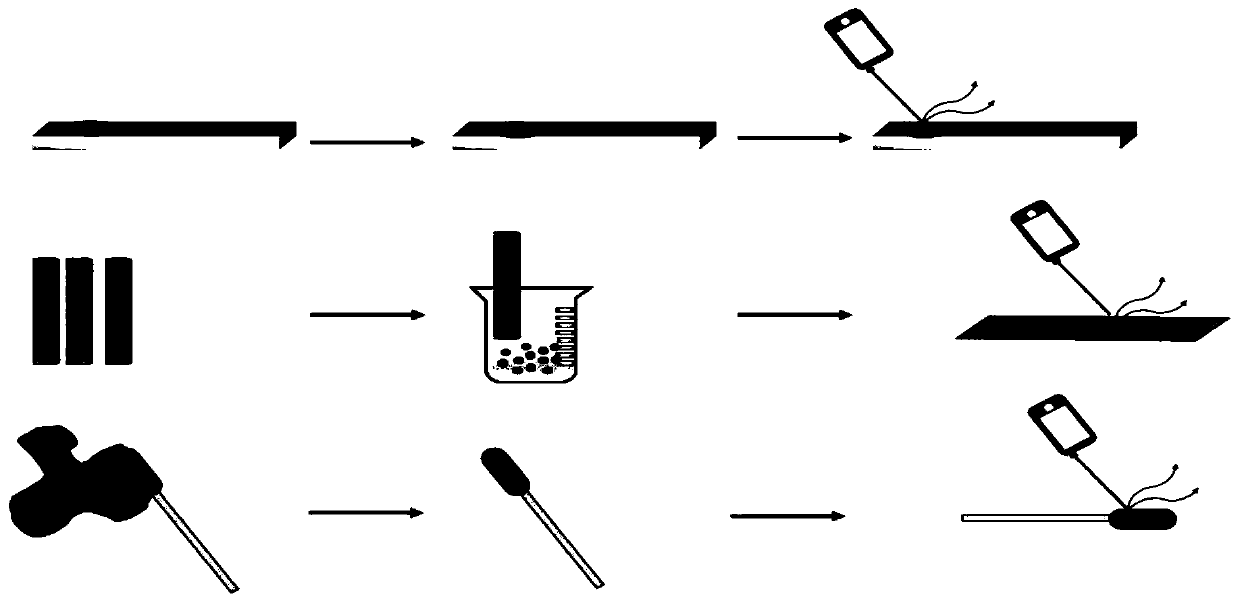

[0050] (3) Vacuum filtration: Pour the AgNPs suspension into a cylindrical funnel, and separate the solid and liquid through a...

Embodiment 2

[0055] (1) Preparation of AgNPs suspension:

[0056] 1. Thoroughly clean glassware with 68% nitric acid;

[0057] 2. Then add 5mL 0.1mM polyvinylpyrrolidone (PVP, Mw~8000) solution and 5mL 2.5% silver nitrate solution into the beaker, and keep it in the ice-water bath for 10 minutes;

[0058] 3. Then 8 mL of 20 mM sodium borohydride was added dropwise to the mixture and stirred for 1.5 hours to form a crude solution of AgNPs;

[0059] 4. The formed AgNPs were collected by centrifugation and washed with deionized water (DI);

[0060] 5. Then disperse the AgNPs in the aqueous solution to prepare a 5 mg / mL AgNPs suspension, and thoroughly disperse the nanoparticles by ultrasonic waves for 30 minutes;

[0061] (2) Nylon filter membrane pretreatment: pretreatment with oxygen, then with plasma cleaning for 2 minutes to remove surface impurity molecules;

[0062] (3) Vacuum filtration: Pour the AgNPs suspension into a cylindrical funnel, and separate the solid and liquid through t...

Embodiment 3

[0065] (1) Preparation of AgNPs suspension:

[0066] 1. Thoroughly clean glassware with 68% nitric acid;

[0067] 2. Then add 8mL 0.2mM polyvinylpyrrolidone (PVP, Mw~8000) solution and 7mL 2.5% silver nitrate solution into the beaker, and keep it in the ice-water bath for 10 minutes;

[0068] 3. Then 5 mL of 20 mM sodium borohydride was added dropwise to the mixture and stirred for 2 hours to form a crude solution of AgNPs;

[0069] 4. The formed AgNPs were collected by centrifugation and washed with deionized water (DI);

[0070] 5. Then disperse the AgNPs in the aqueous solution to prepare a 3 mg / mL AgNPs suspension, and thoroughly disperse the nanoparticles by ultrasonic waves for 30 minutes;

[0071] (2) Nylon filter membrane pretreatment: pretreatment with oxygen, then with plasma cleaning for 2 minutes to remove surface impurity molecules;

[0072] (3) Vacuum filtration: Pour the AgNPs suspension into a cylindrical funnel, and separate the solid and liquid through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com