Carbon fiber polyamide prepreg preparation device and preparation method thereof

A technology for preparing equipment and carbon fiber, which is applied in the direction of coating, etc., can solve the problems of weak bonding ability of resin and carbon fiber, large porosity of coating machine coating, and toxicity of solution, and achieve strong adhesion, small porosity, and no Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

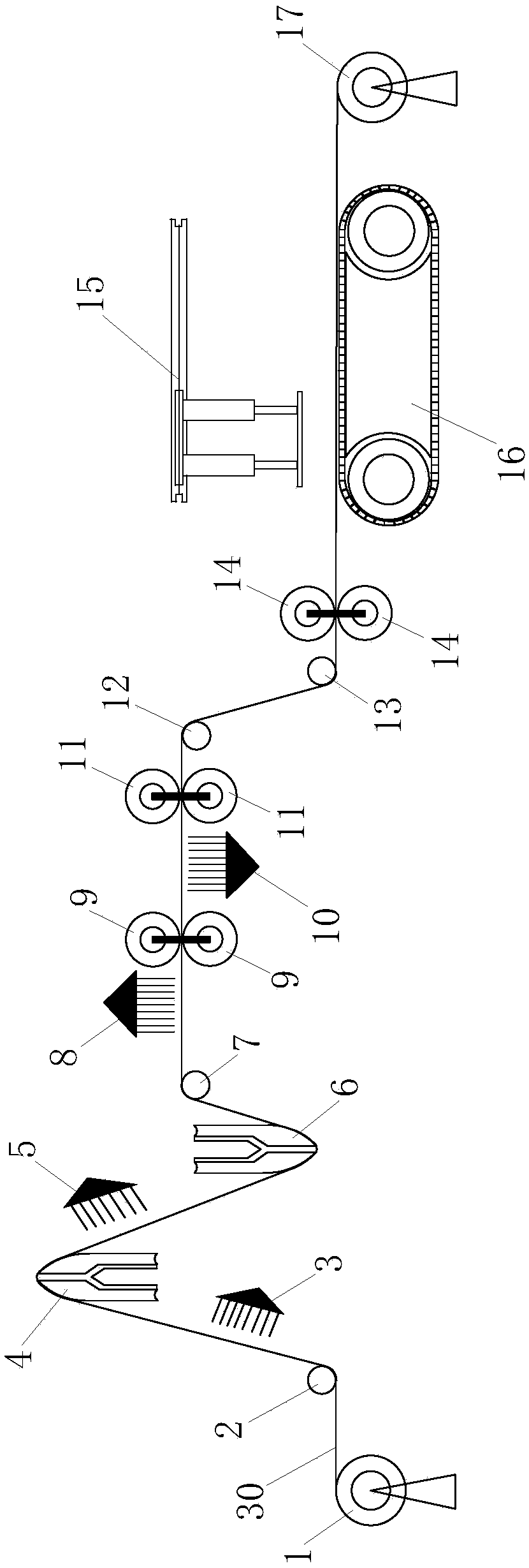

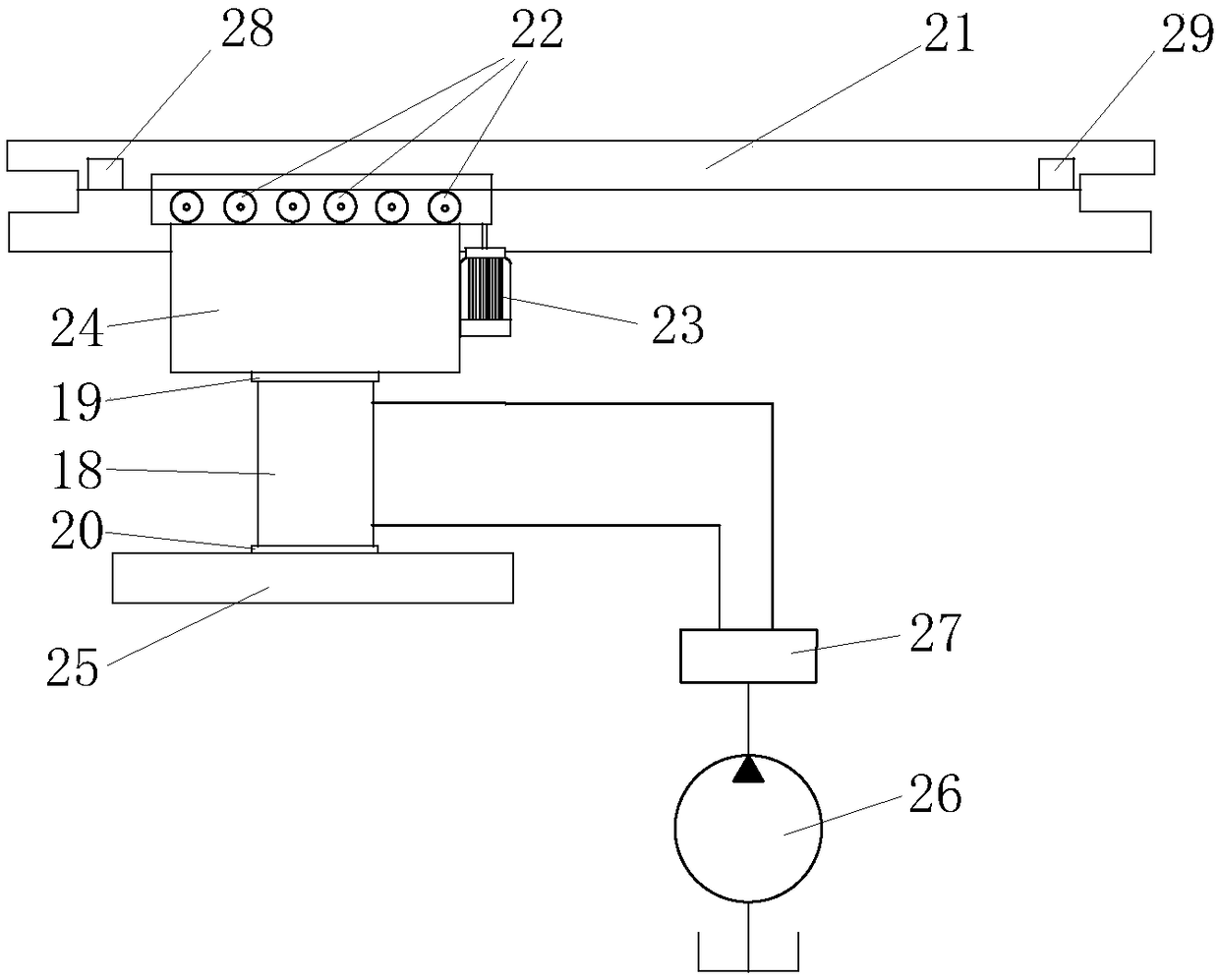

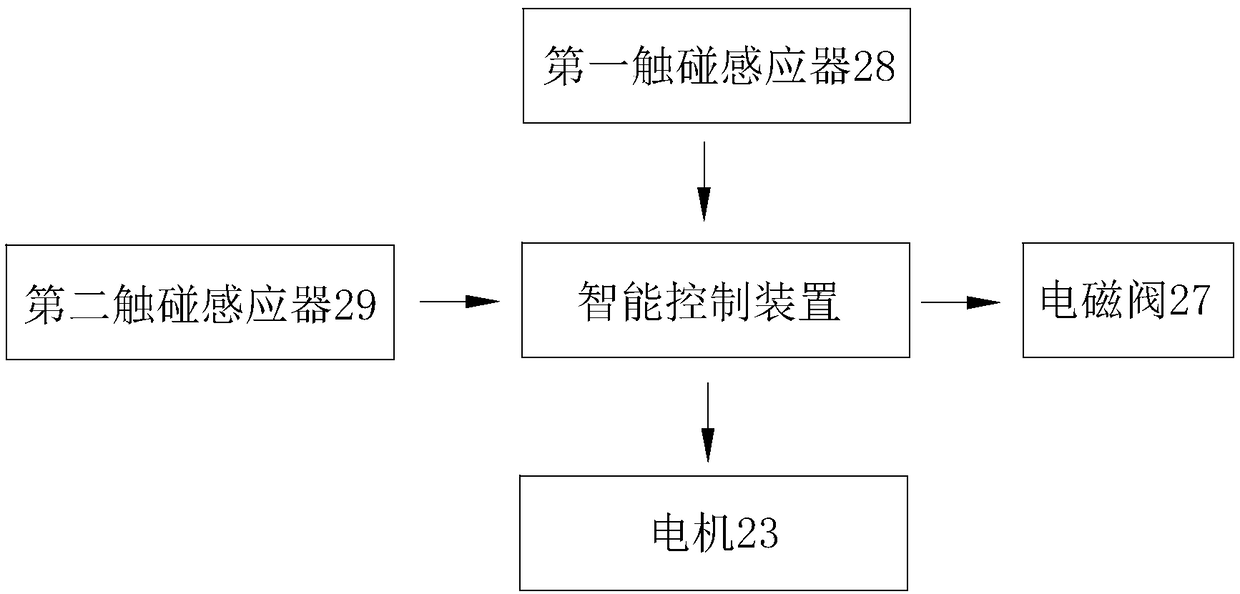

[0028] Depend on figure 1 As shown, the present invention provides a carbon fiber polyamide prepreg preparation device, which is sequentially provided with a carbon fiber pulley 1, a first tension pulley 2, a first infrared heater 3, a first U-shaped molten resin from left to right Nozzle 4, second infrared heater 5, second U-shaped molten resin nozzle 6, second tension wheel 7, third infrared heater 8, first heating roller 9, fourth infrared heater 10, second heating roller 11. The third tensioning wheel 12, the fourth tensioning wheel 13, the cooling roller 14, the press 15 and the conveyor belt 16, the driving roller 17; the first tensioning wheel 2, the first U-shaped molten resin nozzle 4, the second U Type molten resin nozzle 6 and the second tensioning wheel 7 are arranged in an N shape; the first heating roller 9, the second heating roller 11, and the cooling roller 14 are all composed of a pair of rollers arranged side by side in the opposite direction of rotation; T...

Embodiment 2

[0034] The present invention provides a kind of carbon fiber polyamide prepreg preparation method, adopts the preparation device of embodiment 1, and the steps are as follows:

[0035] (1) Carbon fiber pretreatment: wash the carbon fiber with tetrahydrofuran solvent, then dry it under vacuum at 60°C for 12 hours, and finally put it into a reflux device with tetrahydrofuran for reflux treatment for 24 hours, and then put it into 60°C Vacuum drying for 12 hours to obtain Carbon fiber with sizing agent; put the carbon fiber without sizing agent into a nitric acid solution with a concentration of 15.2mol / L, keep it at 60°C for 40min, take it out and wash it with tetrahydrofuran, put it in a vacuum at 40°C for 12h, and complete Surface treatment of carbon fiber; finally get pre-treated carbon fiber;

[0036] (2) Preparation of molten resin: After uniformly mixing polyamide and polyphenylene ether grafted maleic anhydride in a weight ratio of 6:4, add the first U-shaped molten resin...

Embodiment 3

[0042] The present invention provides a kind of carbon fiber polyamide prepreg preparation method, adopts the preparation device of embodiment 1, and the steps are as follows:

[0043] (1) Carbon fiber pretreatment: wash the carbon fiber with tetrahydrofuran solvent, then dry it under vacuum at 60°C for 12 hours, and finally put it into a reflux device with tetrahydrofuran for reflux treatment for 24 hours, and then put it into 60°C Vacuum drying for 12 hours to obtain Carbon fiber with sizing agent; put the carbon fiber without sizing agent into a nitric acid solution with a concentration of 15.2mol / L, keep it at 60°C for 40min, take it out and wash it with tetrahydrofuran, put it in a vacuum at 40°C for 12h, and complete Surface treatment of carbon fiber; finally get pre-treated carbon fiber;

[0044](2) Preparation of molten resin: After uniformly mixing polyamide and polyphenylene ether grafted maleic anhydride in a weight ratio of 6:4, add the first U-shaped molten resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

| Thermal deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com