Preparation method of titanium surface multilevel porous structure

A technology with multi-level pores and mass concentration, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of low bone tissue bonding strength, low bioactivity of titanium and titanium alloys, etc., to promote bonding and improve Osteoblast function, effect of contact promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

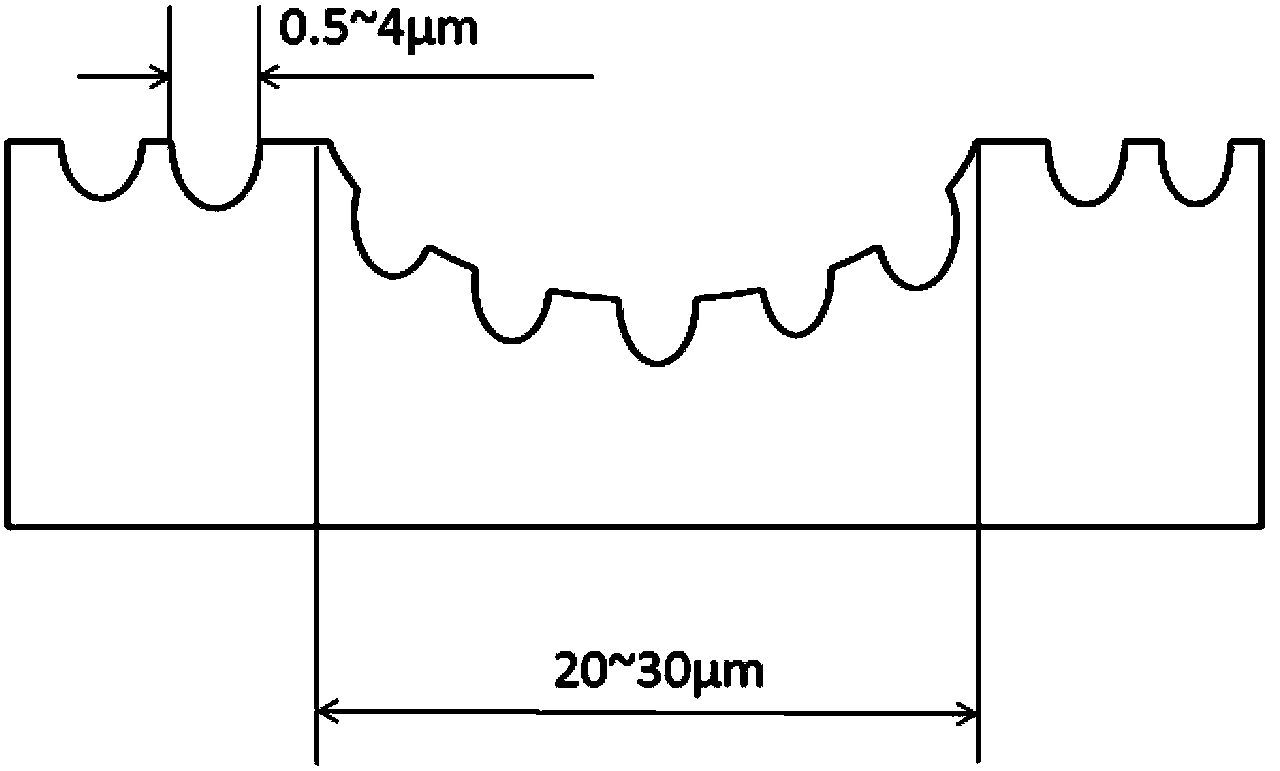

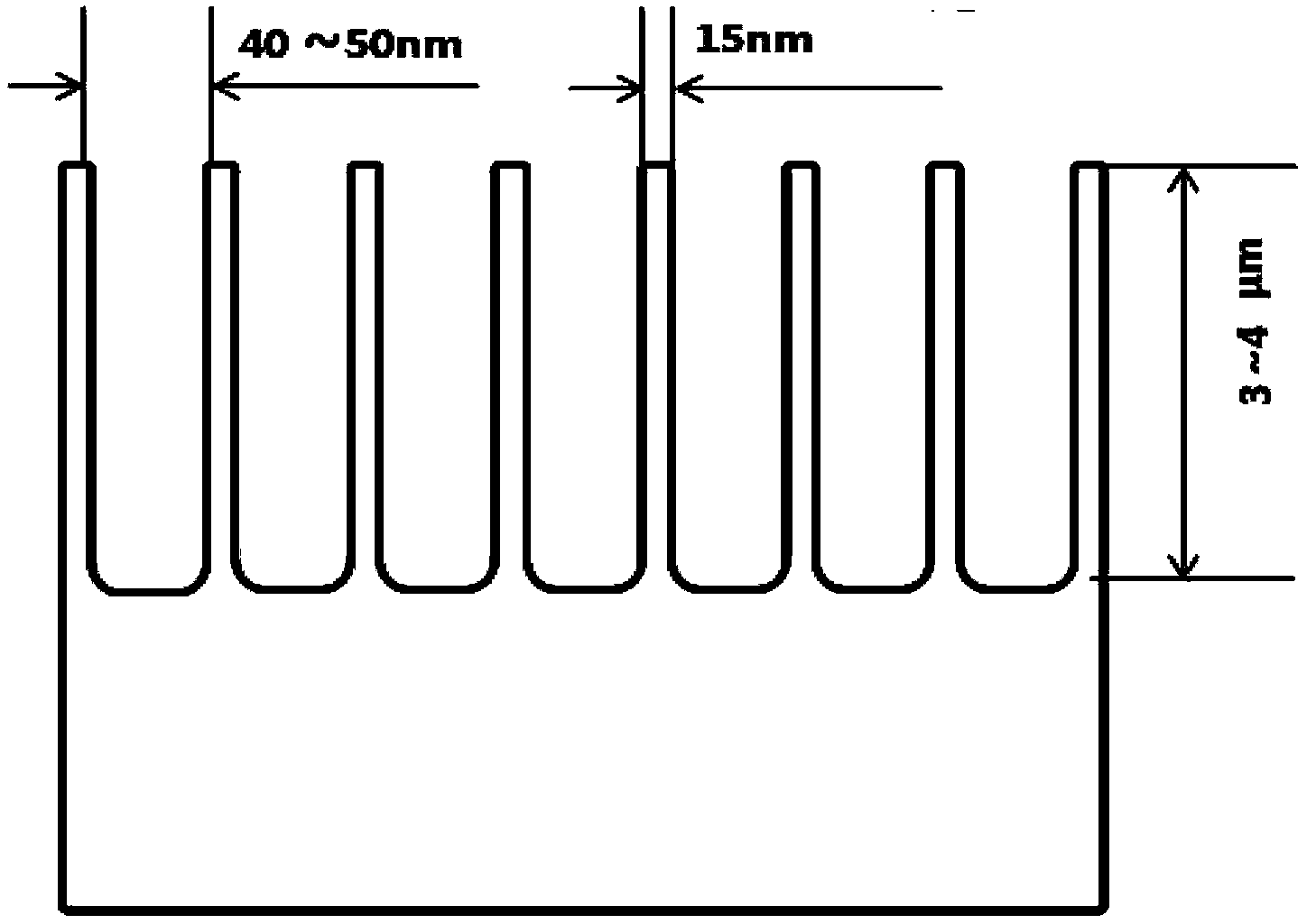

[0012] Specific embodiment one: the method for preparing the titanium surface hierarchical porous structure in this embodiment is carried out through the following steps: 1. The titanium material is polished step by step with 240 mesh, 600 mesh and 1000 mesh metallographic sandpaper, and then successively use Ultrasonic cleaning with acetone and absolute ethanol for 10 to 15 minutes and drying to obtain the treated titanium material; 2. Sandblasting the titanium material treated in step 1 with alumina particles; 3. Sandblasting the titanium material after the sandblasting treatment Soak in a sulfuric acid solution with a mass concentration of 40% to 60% at 40°C to 60°C for 30 to 60 minutes to obtain an acid-etched titanium material; 4. Use the acid-etched titanium material as the anode and platinum as the cathode , placed in NH with a mass concentration of 1-2 g / L 4 F aqueous solution, under the voltage of 20 ~ 30V, anodize treatment for 20 ~ 30min, obtain the titanium materia...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium material is pure titanium or titanium alloy. Others are the same as the first embodiment.

[0016] The pure titanium in this embodiment is industrial pure titanium TA1, TA2, TA3 or TA4.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the particle size of alumina particles in the oxygen sand blasting treatment in the step two is 100-500 μm, the treatment air pressure is 50-60KPa, and the sand blasting time is 1 ~2min. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com