Metal terminal block adapted for surface mounting and method of mounting the same

A metal wiring and surface mount technology, which is applied in the field of metal wiring terminals, can solve the problems of thin flexible printed circuit board, weak welding strength, and large contact resistance, etc., and achieve the effect of enlarged grounding area, easy welding, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described below with reference to the accompanying drawings.

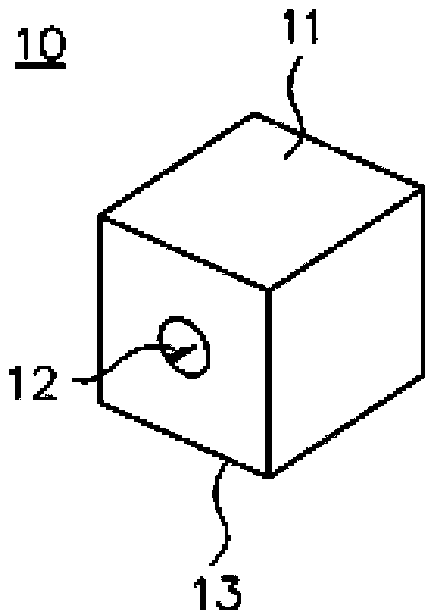

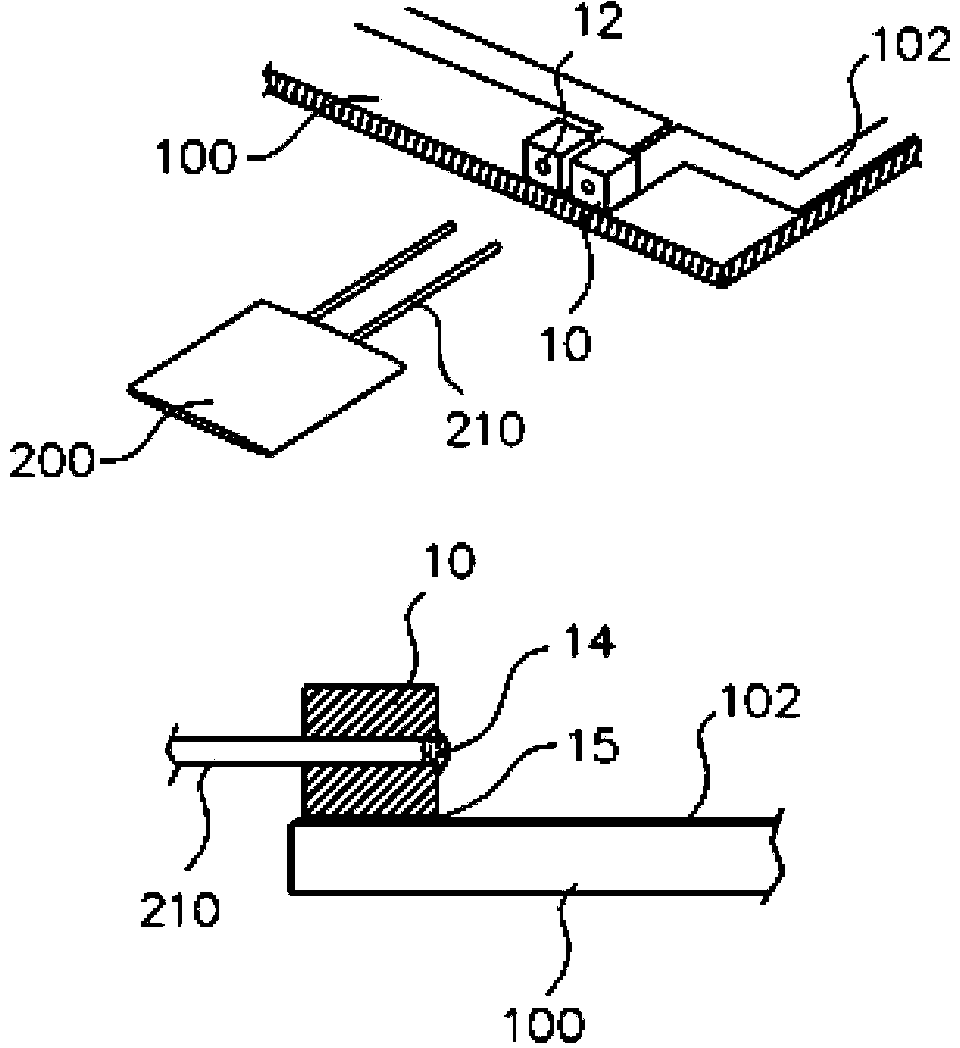

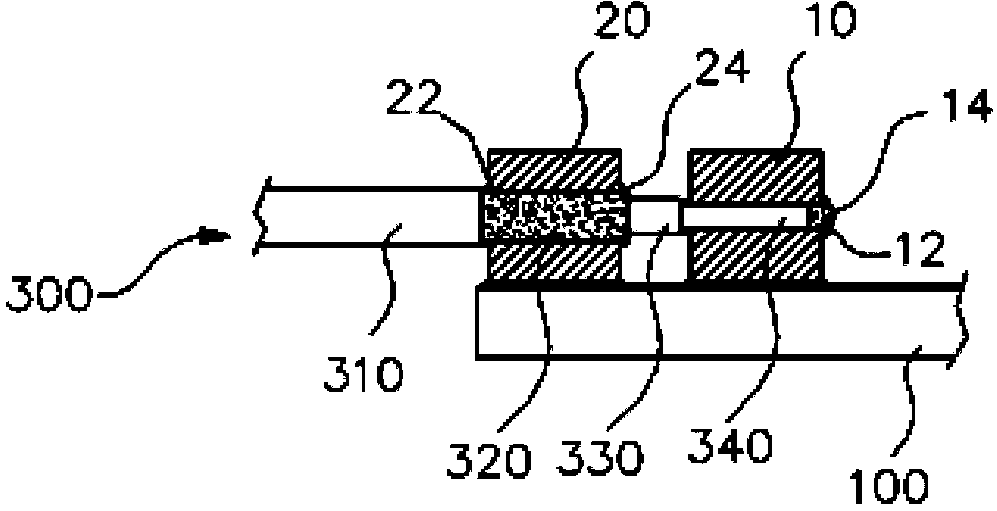

[0044] figure 1 Shown is a metal connection terminal 10 according to one embodiment of the present invention, figure 2 Shown are a state in which a metal terminal is applied to a circuit board and a state in which a metal lead of a thermistor as an electronic component is bonded to the metal terminal.

[0045] As shown in the figure, the metal connection terminal 10 has a three-dimensional shape, for example, a hexahedron shape, and the surface 11 and the bottom surface 13 are horizontal planes and formed of a single body of metal material. Since the bottom surface 13 is a horizontal plane, reflow soldering can be performed; since the surface 11 is a horizontal plane, surface mounting can be performed by vacuum pick-up.

[0046] Insertion holes 12 are formed through the front and rear sides to insert core wires of cables or metal leads of electronic components,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com