Underwater unmanned remote-control heavy-load work vehicle

The technology of a working vehicle and a frame is applied in the field of underwater unmanned remote control heavy-duty working vehicles, which can solve the problems of reducing the accuracy of mineral exploration, and achieve the effects of improving the performance of crossing the ditch, reducing the disturbance and enhancing the passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

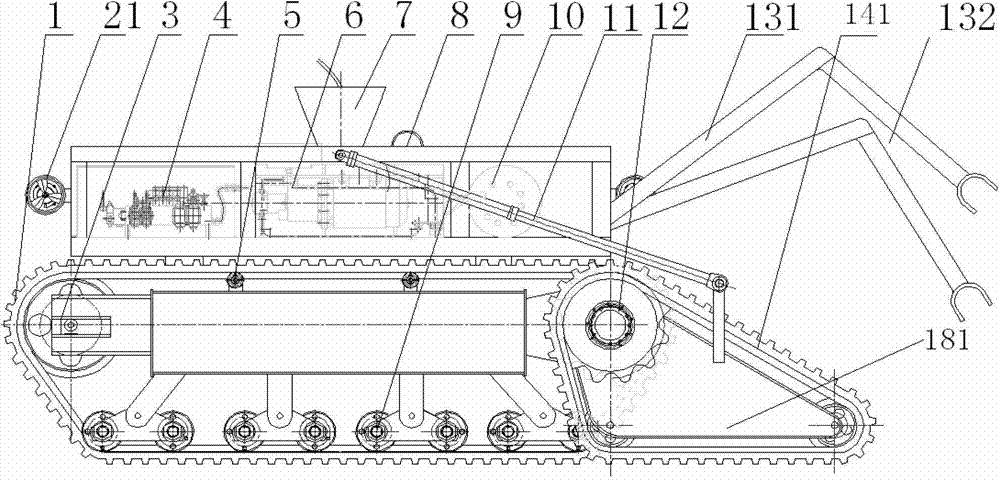

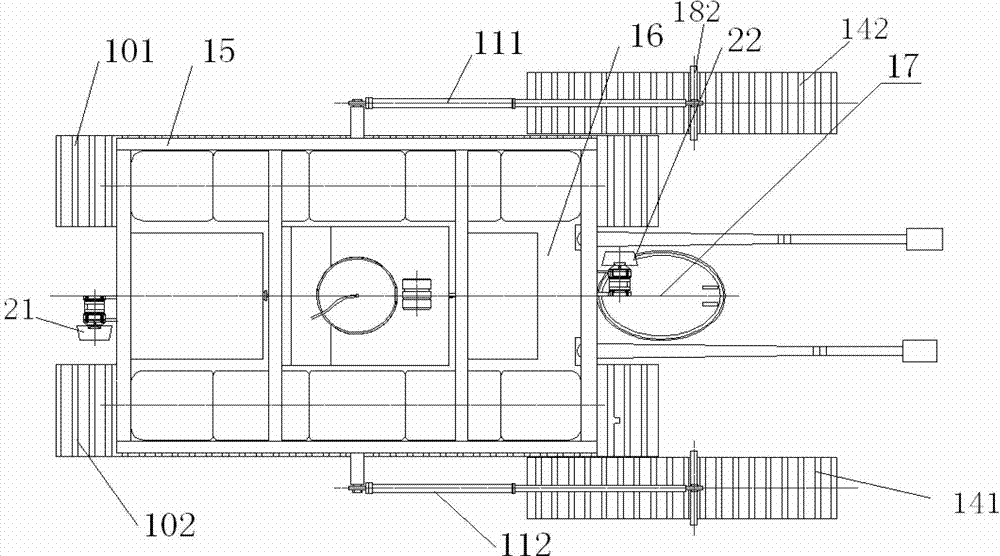

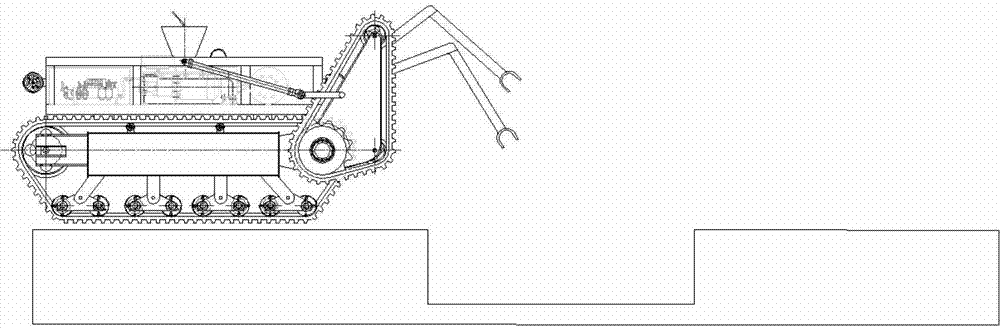

[0034] see figure 1 and figure 2, the main body of the work vehicle adopts the crawler walking mode, the vehicle frame 15 is high from the ground, the first walking crawler 101 and the second walking crawler 102 are rubber wide crawlers, the involute tooth shape is adopted, and the floating roller 9 is adopted, which has a large approach angle and departure angle. The electronic cabin 10, the hydraulic valve cabin 4, and the hydraulic pump station cabin 6 are independently arranged on the vehicle frame 15, and a pressure compensation device 8 and a cable protective net cover 7 are installed at the same time. In addition, a rear propeller 21 and a front propeller 22 are installed at the center of front and rear symmetry of the vehicle frame 15, and their rotation axes are parallel to the axis of the driven wheel 3 of the walking track, and are arranged oppositely to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com