Super-thick metal anticorrosive coat and preparation technology thereof

A technology of metal anti-corrosion and preparation technology, applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve problems such as difficult to prepare, thick coatings, etc., and achieve the effect of strengthening the mechanical bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

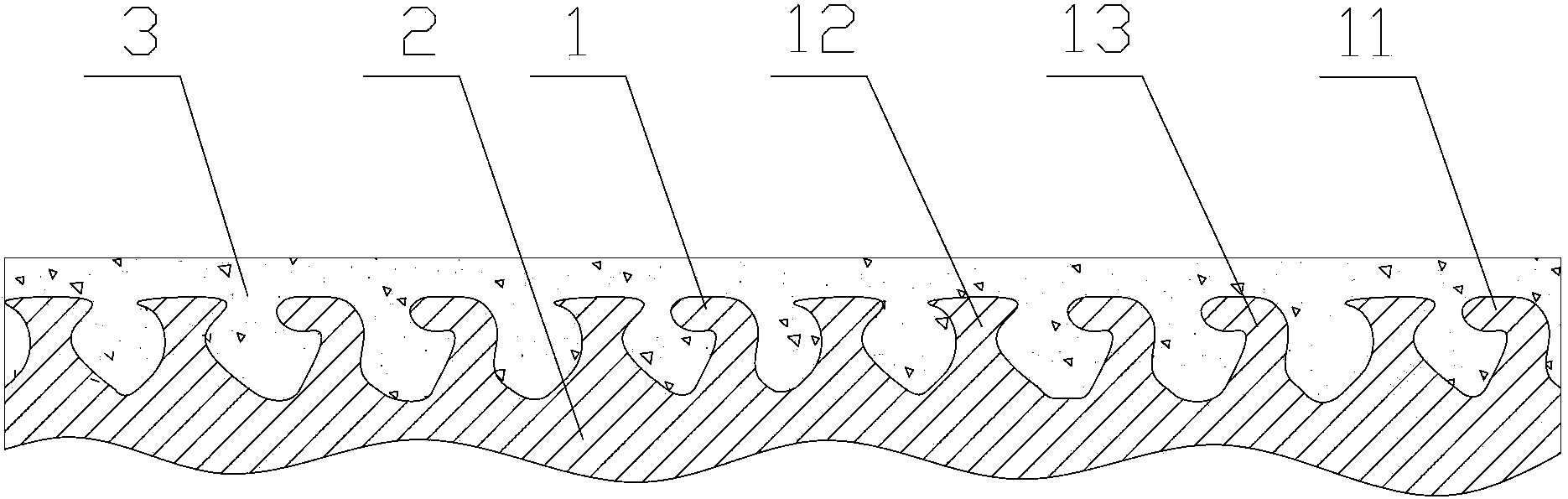

[0024] Ultra-thick metal anti-corrosion coatings, such as figure 1 As shown, it includes a metal substrate 2, a metal substrate anchor layer 1, and an anti-corrosion metal layer 3. The surface roughness of the metal substrate 2 is 300 μm, and the surface of the metal substrate 2 is provided with a metal substrate anchor layer. 1. The anchor hook layer 1 of the metal substrate includes a flat anchor hook 11, and the metal substrate 2 is embedded and anchored with the anti-corrosion metal layer 3 through the anchor hook layer 1 of the metal substrate. The metal base material 2 is connected to the anti-corrosion metal layer 3 through the metal base anchor hook layer 1 and the anti-corrosion metal layer 3. necessary conditions.

[0025] The flat-headed anchor hook 11 has a mushroom-shaped anchor pattern 12 and a hook-shaped anchor pattern 13. The cross-section of the mushroom-shaped anchor pattern 12 is a "T" shape, and the cross-section of the hook-shaped anchor pattern 13 is a ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the surface roughness of the metal substrate 2 is 651 μm. The metal base material 2 is connected to the anti-corrosion metal layer 3 through the metal base anchor layer 1 and the anti-corrosion metal layer 3. The mechanical bonding force between the anti-corrosion metal layer 3 and the metal base material 2 is improved, and the thickness of the anti-corrosion metal layer 3 is increased. necessary conditions.

[0033] The preparation process of the ultra-thick metal anti-corrosion coating comprises the following steps: a. preparing anchor patterns with a roughness of 651 μm on the surface of the metal substrate 2; b. applying pressure to the anchor patterns of the metal substrate 2 to form the anchor hooks of the metal substrate Layer 1; c, preparing an anti-corrosion metal layer 3 with a thickness of 1110 μm. In step b, the anchor pattern of the metal substrate 2 is pressed by rolling. In step c, the anti...

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the surface roughness of the metal substrate 2 is 731 μm. Prepare a roughness of 921 μm on the surface of the metal substrate 2, and form the anchor hook layer 1 of the metal substrate by applying pressure to the anchor pattern of the metal substrate 2, so that the original surface area of the metal substrate 2 is the same as the prepared roughness and the anchor hook. The ratio of the expanded area after the layer reaches 1: (1.6-4). The thickness of the anti-corrosion metal layer 3 reaches 1310 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com