Thermoplastic composite pipe with sealing and buckling joint, and manufacturing method

A technology of thermoplastics and crimping joints, which is applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, mechanical equipment, etc., can solve problems such as bulging and bursting of the outer protective layer, and structural instability of composite pipes, so as to achieve high production efficiency and improve production efficiency. Effect of sealing performance and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

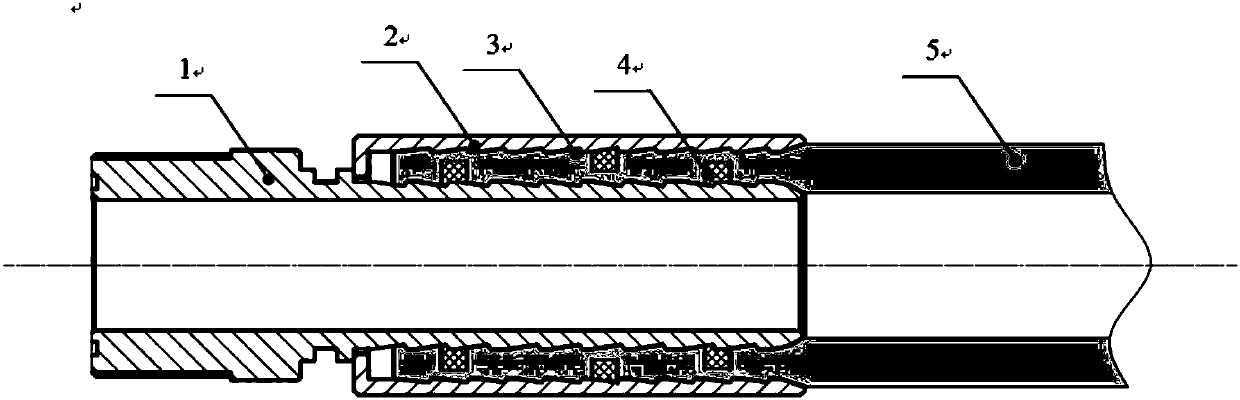

[0036] Improving the sealing performance of polyester fiber reinforced polyethylene composite pipe joints.

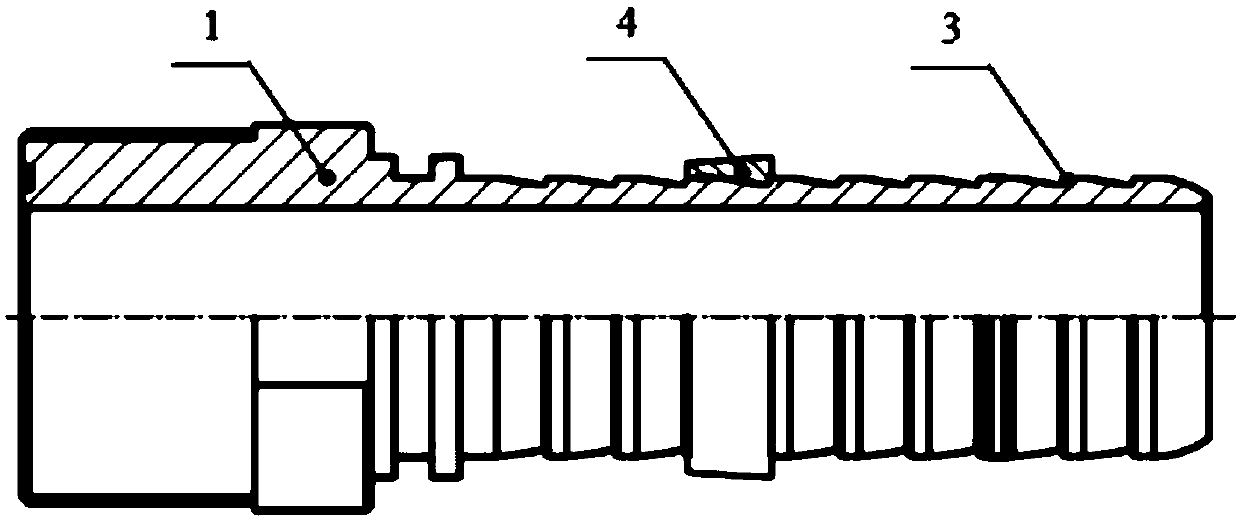

[0037](1) Shape memory alloy ring processing: select a shape memory alloy material with a transformation temperature of 25°C, adjust the indoor temperature to >25°C, and process the shape memory alloy ring 4 to ensure that the inner diameter of the shape memory alloy ring 4 is the same as the outer diameter of the core tube 1, The width of the shape memory alloy ring 4 is 10 mm, the minimum wall thickness is 5 mm, and the wedge angle of the outer surface of the shape memory alloy ring 4 is 10°; (2) Assembly of the shape memory alloy ring: assemble two pieces of shape memory alloy ring 4 to the outside of the core tube 1 , 2 shape-memory alloy rings 4 with a pitch of 5 sawtooth teeth (3); (3) shape-memory alloy ring treatment: adjust the indoor temperature 25°C, the shape memory alloy ring 4 will slowly and automatically recover the shape before the treatment, and its th...

Embodiment 2

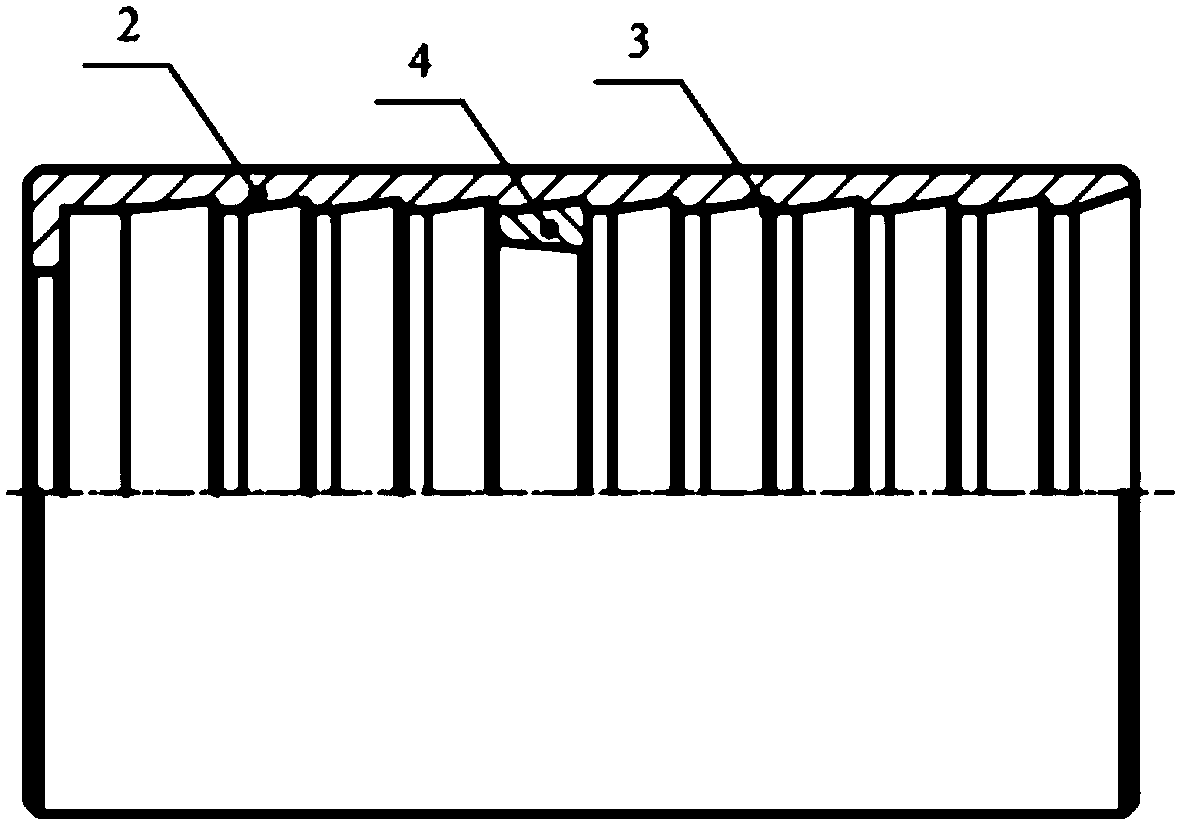

[0039] Improving the sealing performance of steel belt reinforced polyethylene composite pipe joints

[0040] (1) Shape memory alloy ring processing: select shape memory alloy materials with a transition temperature of 20°C, adjust the indoor temperature to >20°C, and process the shape memory alloy ring 4 to ensure that the diameter of the shape memory alloy ring 4 is the same as the inner diameter of the sleeve 2, and the shape The width of the memory alloy ring 4 is 12 mm, the minimum wall thickness is 6 mm, and the wedge angle of the inner surface of the shape memory alloy ring 4 is 15°; (2) Assembly of the shape memory alloy ring: assemble three pieces of shape memory alloy rings 4 to the inside of the sleeve 2, 3 pieces of shape memory alloy rings 4 have a pitch of 4 sawtooth teeth; (3) shape memory alloy ring treatment: adjust the indoor temperature 20°C, the shape memory alloy ring 4 will slowly and automatically recover the shape before the treatment, and its thickness...

Embodiment 3

[0042] Improving the sealing performance of continuous glass fiber tape reinforced polyethylene composite pipe joints

[0043] (1) Shape memory alloy ring processing: select a shape memory alloy material with a transformation temperature of 25°C, adjust the indoor temperature to >25°C, and process shape memory alloy rings matching the outer diameter of the core tube 1. The width of the shape memory alloy ring 4 is is 11mm, the minimum wall thickness is 5.5mm, and the wedge angle of the outer surface of the shape memory alloy ring 4 is 10°; at the same time, the shape memory alloy ring 4 matching the inner diameter of the sleeve 2 is processed, and the width of the shape memory alloy ring 4 is 10mm, and the minimum The wall thickness is 4mm, and the wedge angle of the inner surface of the shape memory alloy ring 4 is 11°; (2) Assembly of the shape memory alloy ring: assemble two shape memory alloy rings 4 to the outside of the core tube 1, and two shape memory alloy rings 4 to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com